Electric adjusting device for pipe shaping

A technology of electric adjustment and adjustment device, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., to achieve the effects of reducing production cost and labor intensity, improving molding efficiency, convenient and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

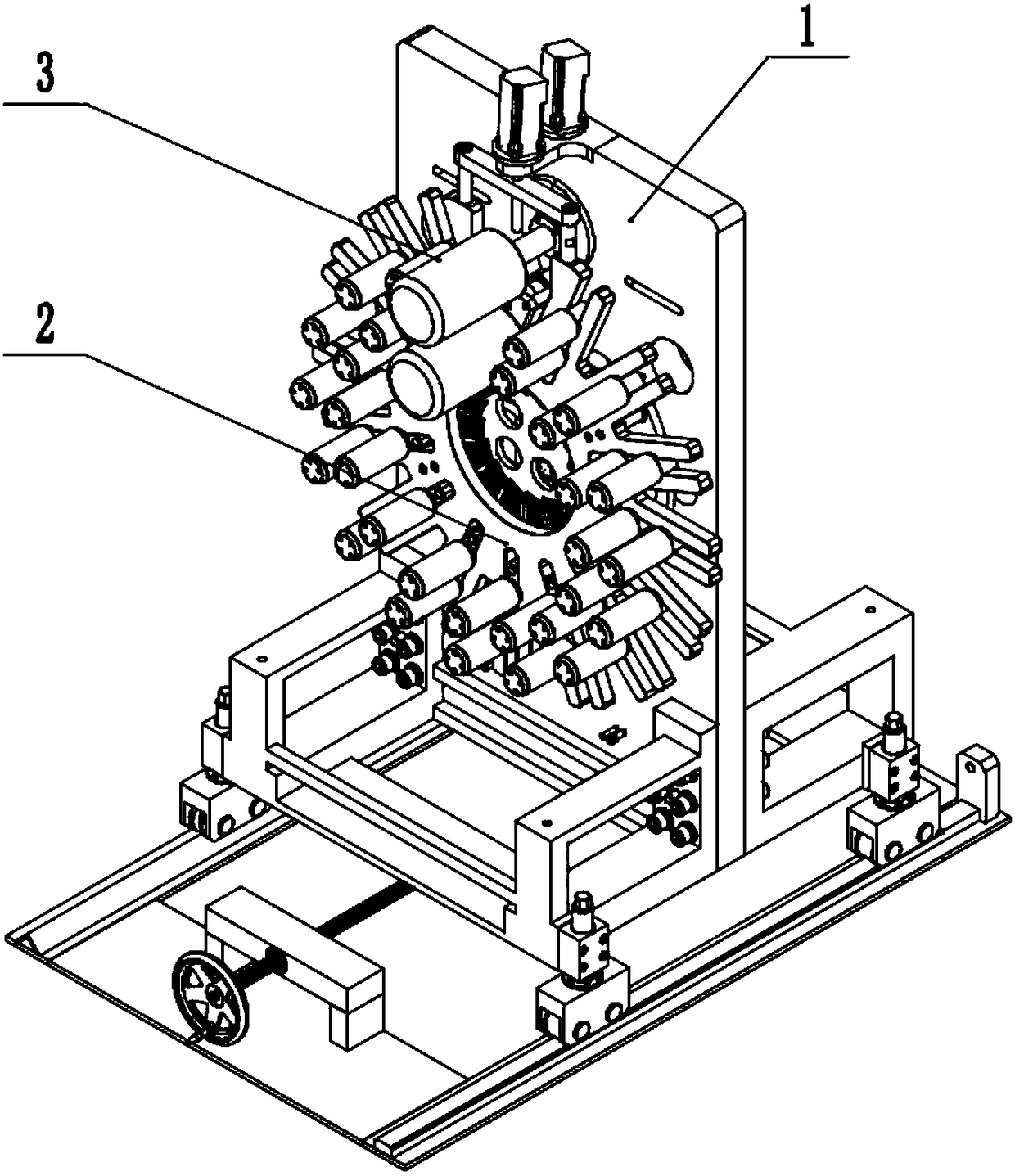

[0027] Such as figure 1 As shown, an electric adjustment device for pipe shaping includes a frame plate 1 and a pipe diameter adjusting structure 2 and a wall thickness adjusting structure 3 installed on the frame plate.

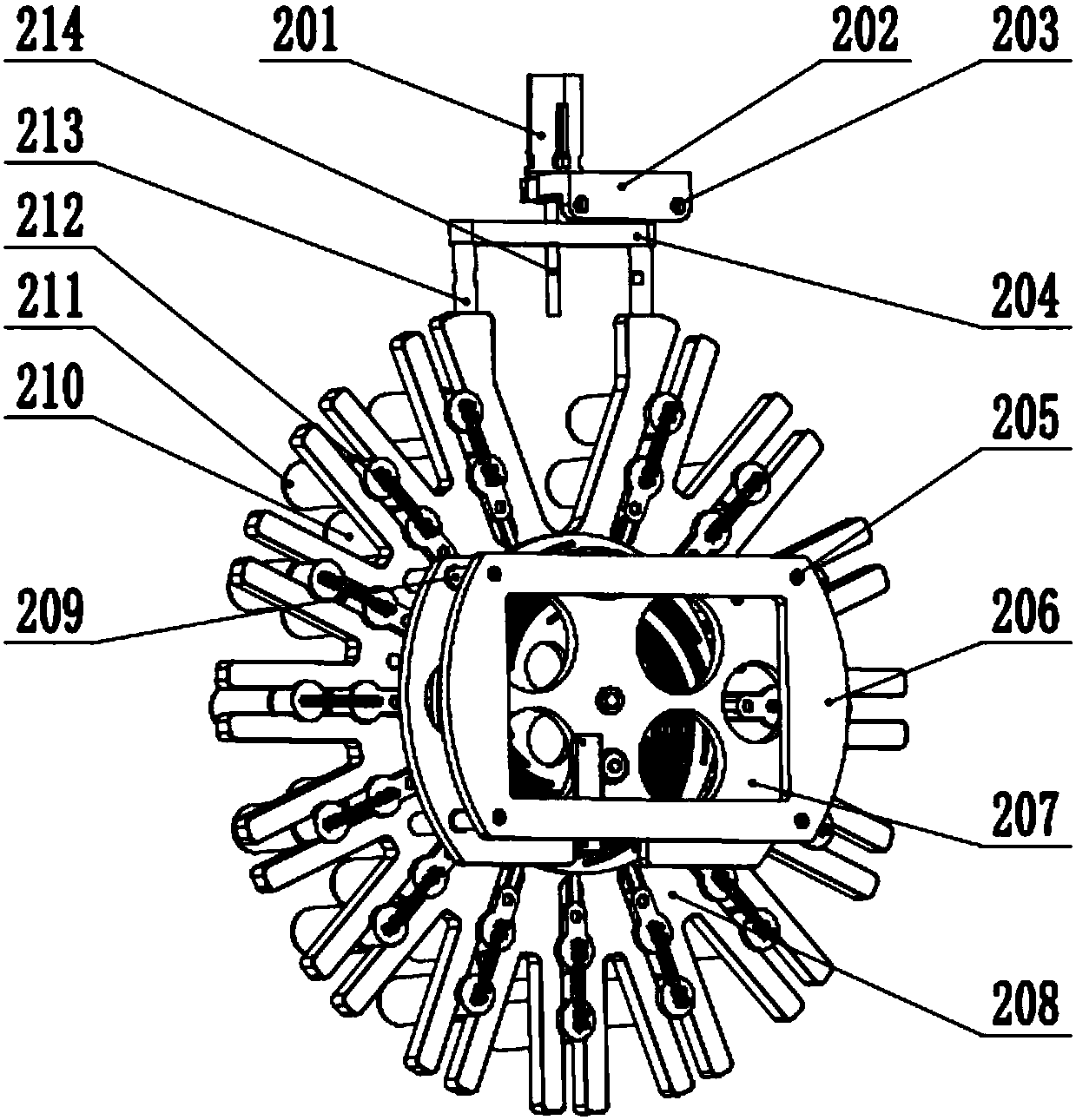

[0028] Such as figure 2 As shown, the pipe diameter adjustment mechanism includes a first screw adjusting device, a sizing wheel support plate 208, a plane screw driving device, a support seat positioning plate 206, a rack 218, a transmission gear set, a support seat positioning pull rod 209 and a support seat 207, the rack 218 is fixed on the frame plate 1, and the support seat positioning pull rod 209 passes through the shaping wheel support plate 208, the support seat and the support seat positioning plate in turn through the second screw 205 and is fixed on the frame plate, The plane screw driving device is rotatably connected to the support base, the rack 218 is drivingly connected with the plane screw driving device through a transmission gear set, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com