Regenerative braking energy feedback system

An energy feedback, regenerative braking technology, applied in electric braking systems, electric vehicles, power management, etc., can solve the problems of high cost, increased volume and cost, and large occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

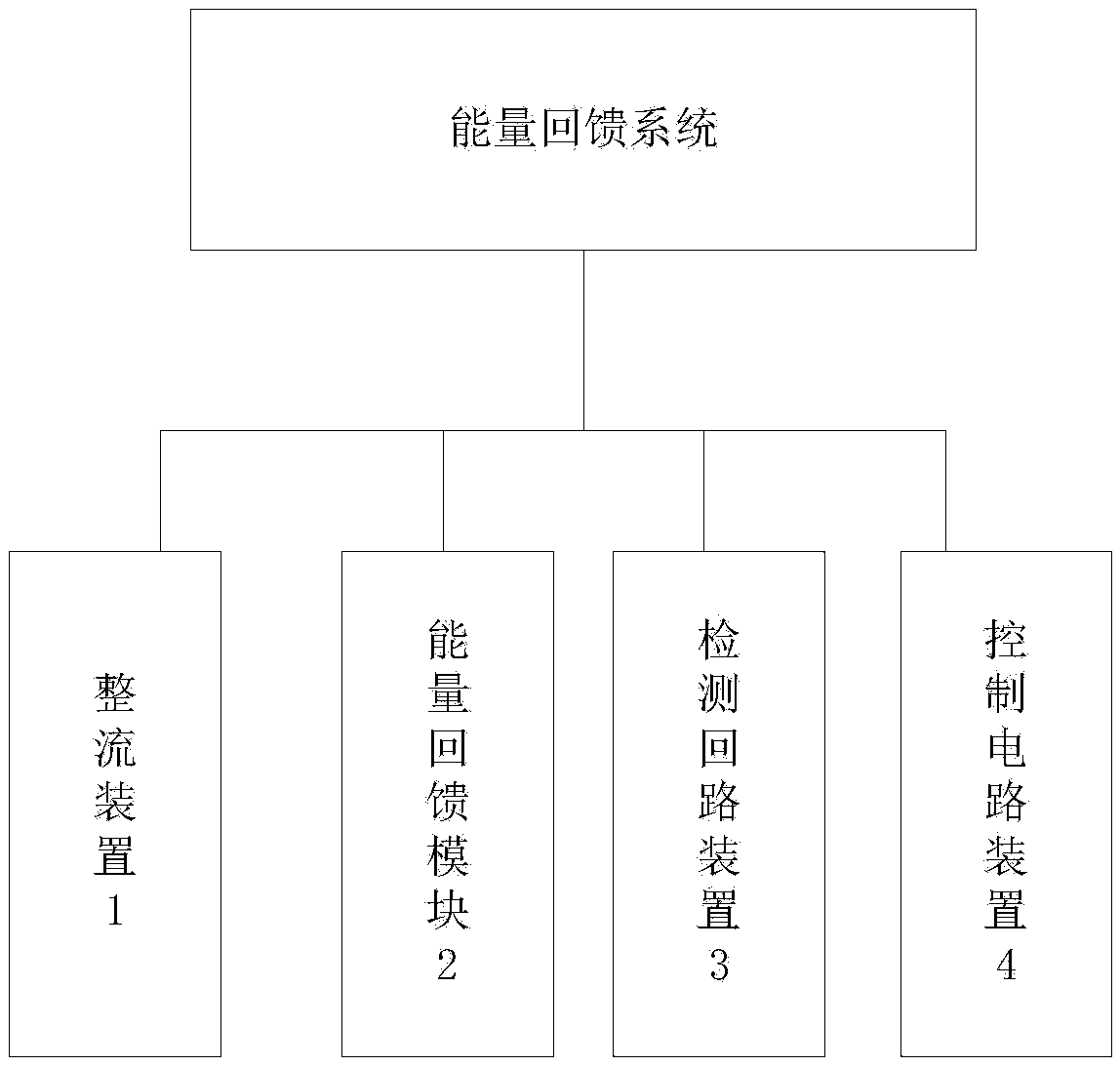

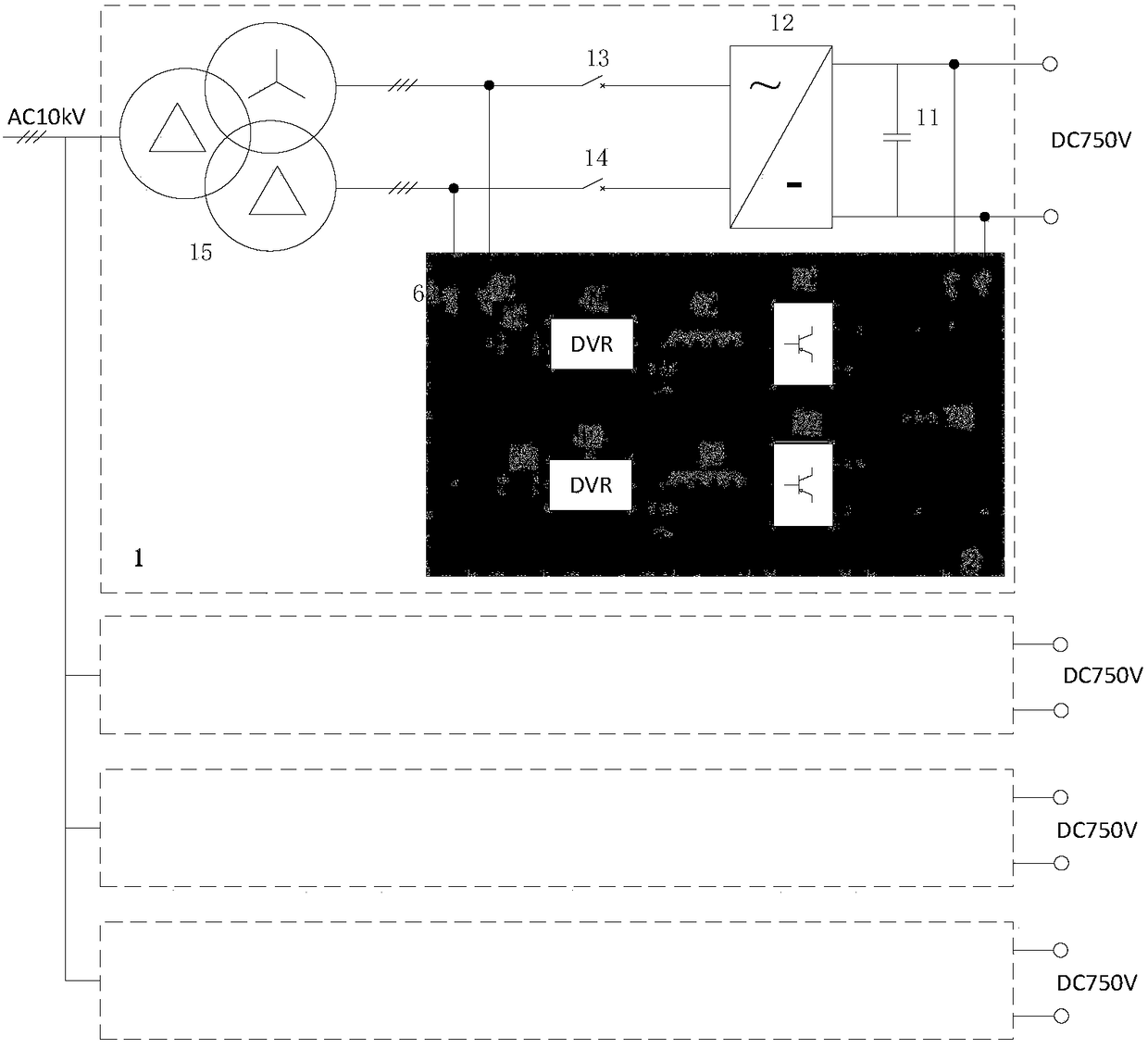

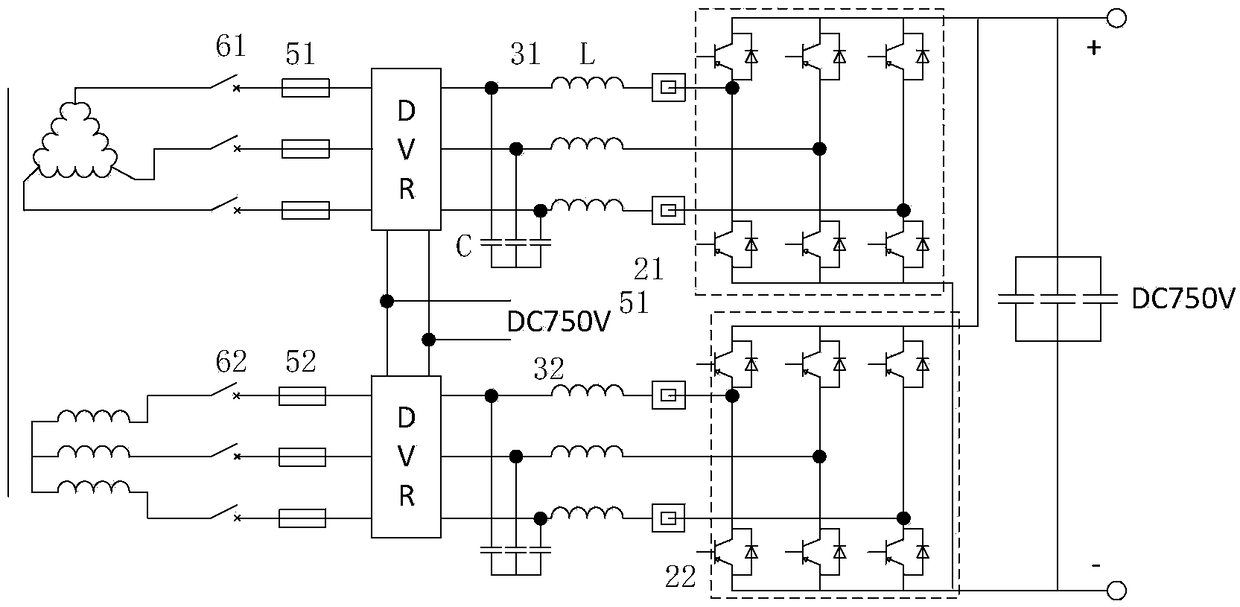

[0073] Such as figure 1 , 2 and 3, a regenerative braking energy feedback system, including the original diode rectifier device 1, energy feedback module 2, detection circuit device 3, control circuit device 4. A set of energy feedback modules 2 are connected in anti-parallel to each of the original diode rectifier devices. The energy feedback modules 2 are also connected to a detection loop device 3, and the detection loop device 3 is also connected to a control circuit device 4.

[0074] According to the three-mode operation of the rectifier power supply system: DC750V / 3MW, DC1500V / 6MW and DC3000V / 9MW, the maximum DC current is 5kA, and the maximum power of the feedback is also 9MW. Set the number of different groups and the connection mode of the device: when DC750V / 3MW When two groups of rectifier devices are connected in parallel, the DC power supply current is 3MW / 750V=4kA, and each set of current is 2kA; when DC1500V / 6MW, two groups of rectifier devices are connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com