Full-automatic transfer machine for freight elevator logistics

A fully automatic, transfer machine technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of low logistics transportation efficiency, large manpower and material resources, and site confusion, saving labor costs and improving logistics transportation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

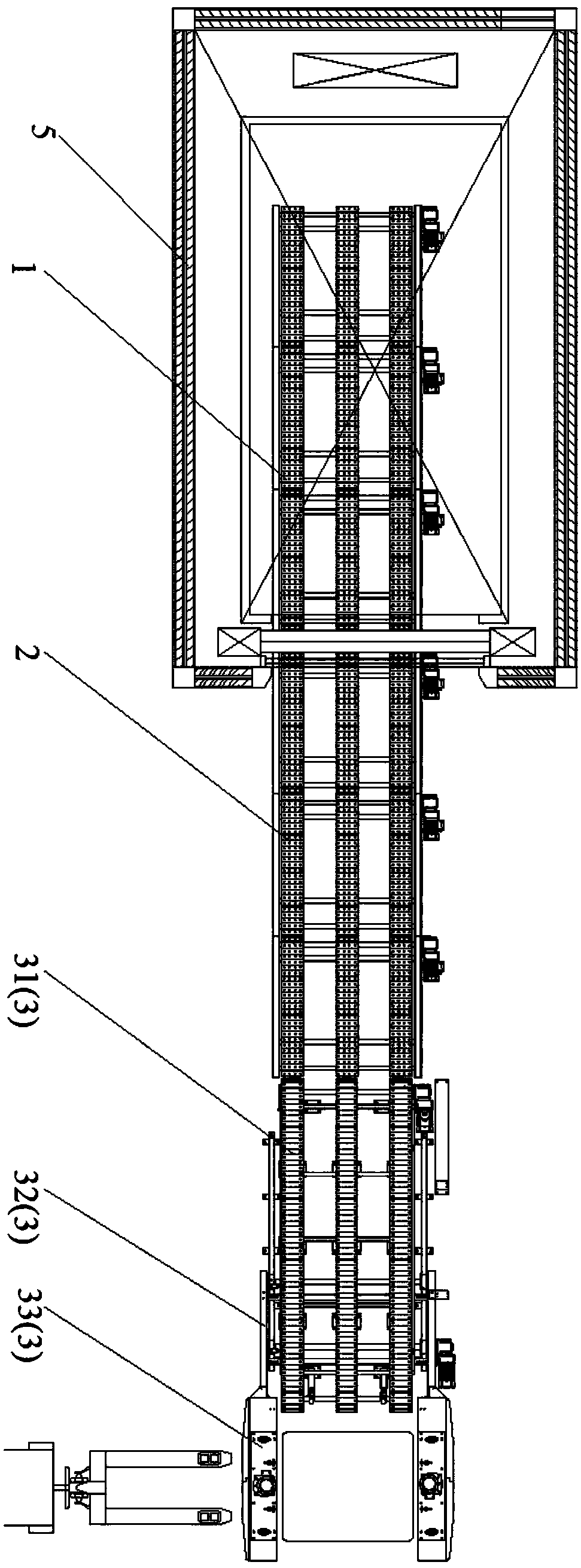

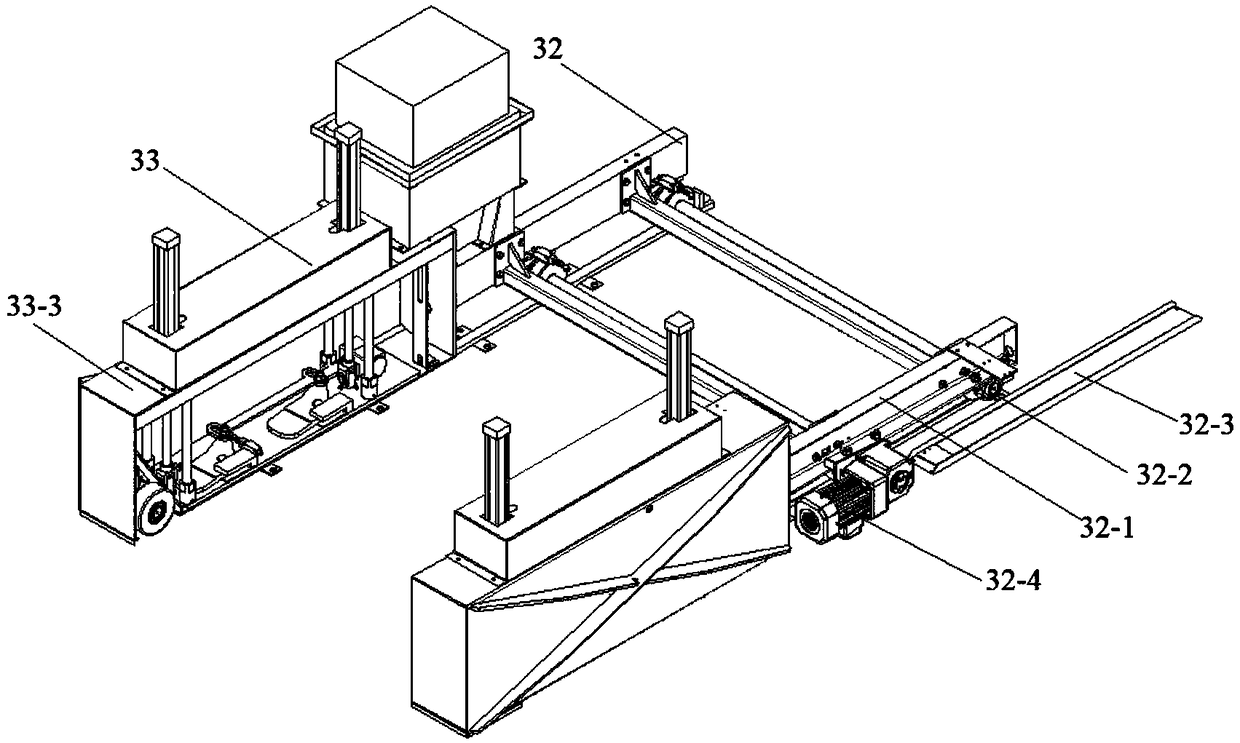

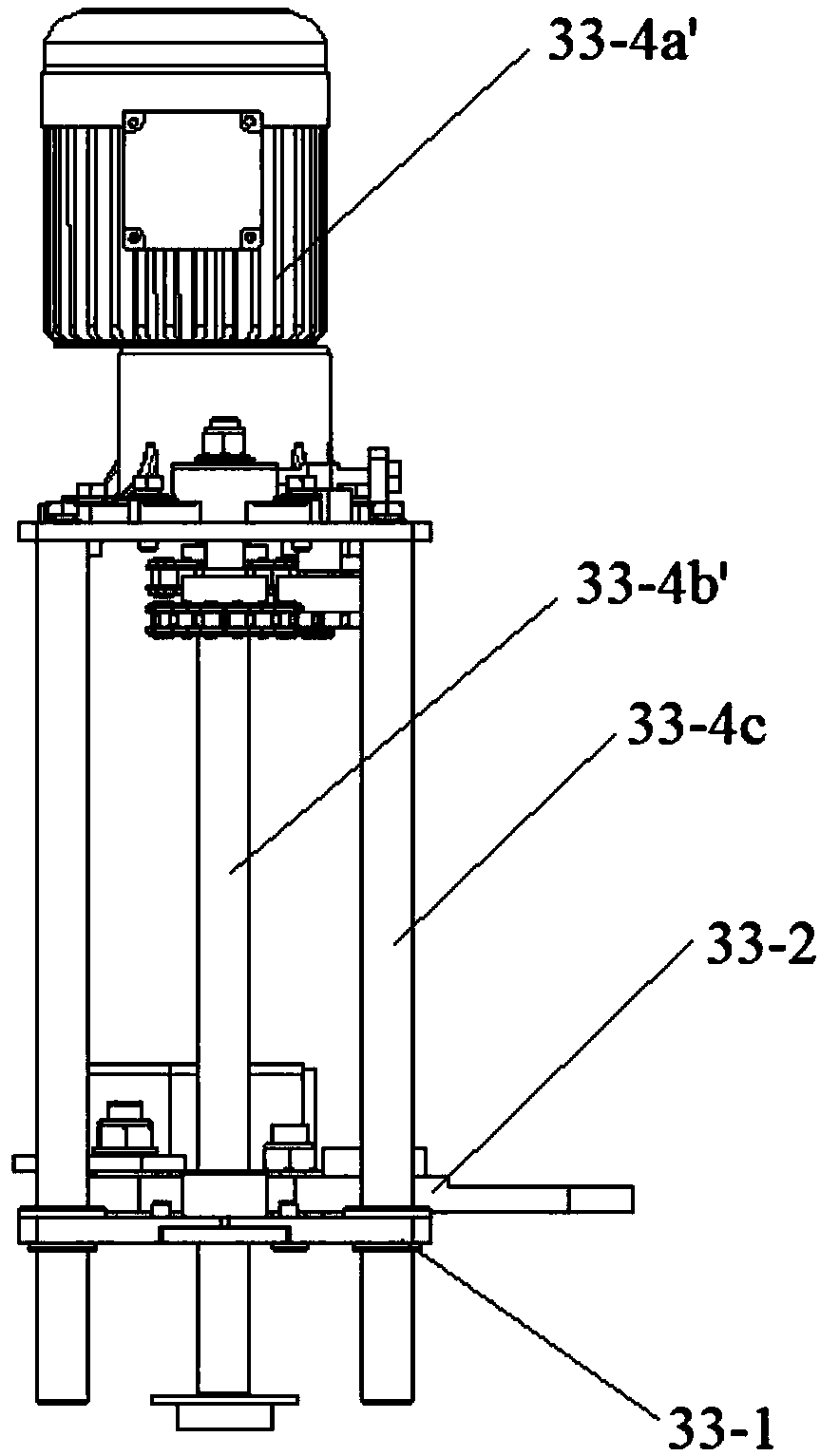

[0043] The invention describes in detail a fully automatic transfer machine for freight elevator logistics. The transfer machine mainly includes an inner conveying line 1, an outer conveying line 2, a lifting and transplanting mechanism 3, an AGV trolley 4 and a control center, and the operation of each part is controlled by the control center. steps and itineraries etc.

[0044] Among them, the inner conveyor line 1 is fixedly laid on the ground in the elevator room 5, and the conveying direction of the inner conveyor line is towards the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com