Unmanned remote control transfer cart

An unmanned, delivery vehicle technology, applied in the field of delivery vehicles, can solve problems such as difficulty in controlling the movement direction of delivery vehicles, prolonging the completion cycle of production tasks, and consequences of the human delivery vehicle production chain, etc., so as to improve the efficiency of logistics transportation and reduce manual labor. Strength, effect of short manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

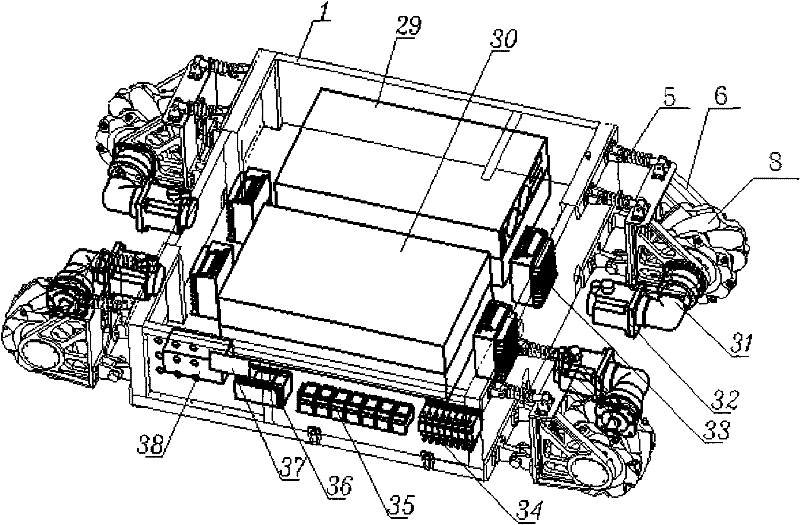

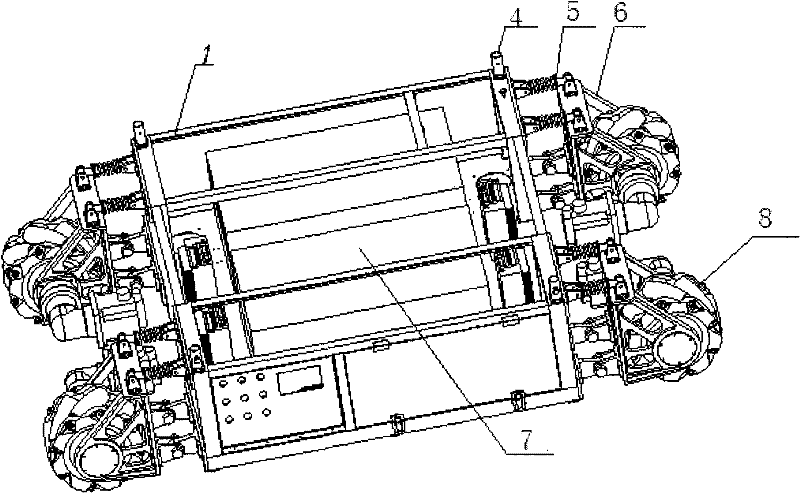

[0016] refer to figure 1 , figure 2 . Car body is made up of compartment 1 and motion mechanism. The carriage consists of a steel body frame and covers. The lower portion of the carriage houses the control system components that are isolated and protected by covers. The control system 7 includes a UPS main unit 29 and a UPS storage battery 30 stacked on the bottom of the compartment 1, and also includes an electrically connected servo motor, a servo motor driver 33 fixed on the UPS storage battery 30 and a relay fixed on the compartment 1 and electrically connected to each other 34. Circuit breaker 35, PLC 36, power supply 38 for supplying power to the control system. The man-machine interface 37 is also housed on the positioning bracket at the side of the compartment 1 .

[0017] The servomotor 32 is fixed on the front and rear side plates of the compartment, and is coaxially connected with the speed reducer 31 . The output shaft of speed reducer 31 links to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com