Circulating logistics device and application method thereof

A logistics and circular line technology, applied in the field of textile dyeing and finishing, can solve the problems of complex conveying paths, further improvement of conveying efficiency, and obstacles to workers' walking, so as to achieve reasonable structural layout, improve logistics conveying efficiency, and facilitate compact layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

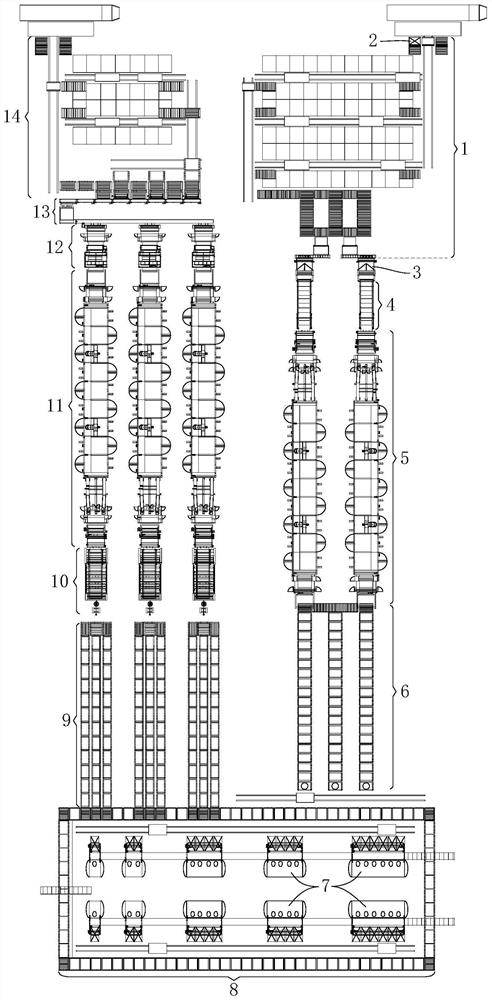

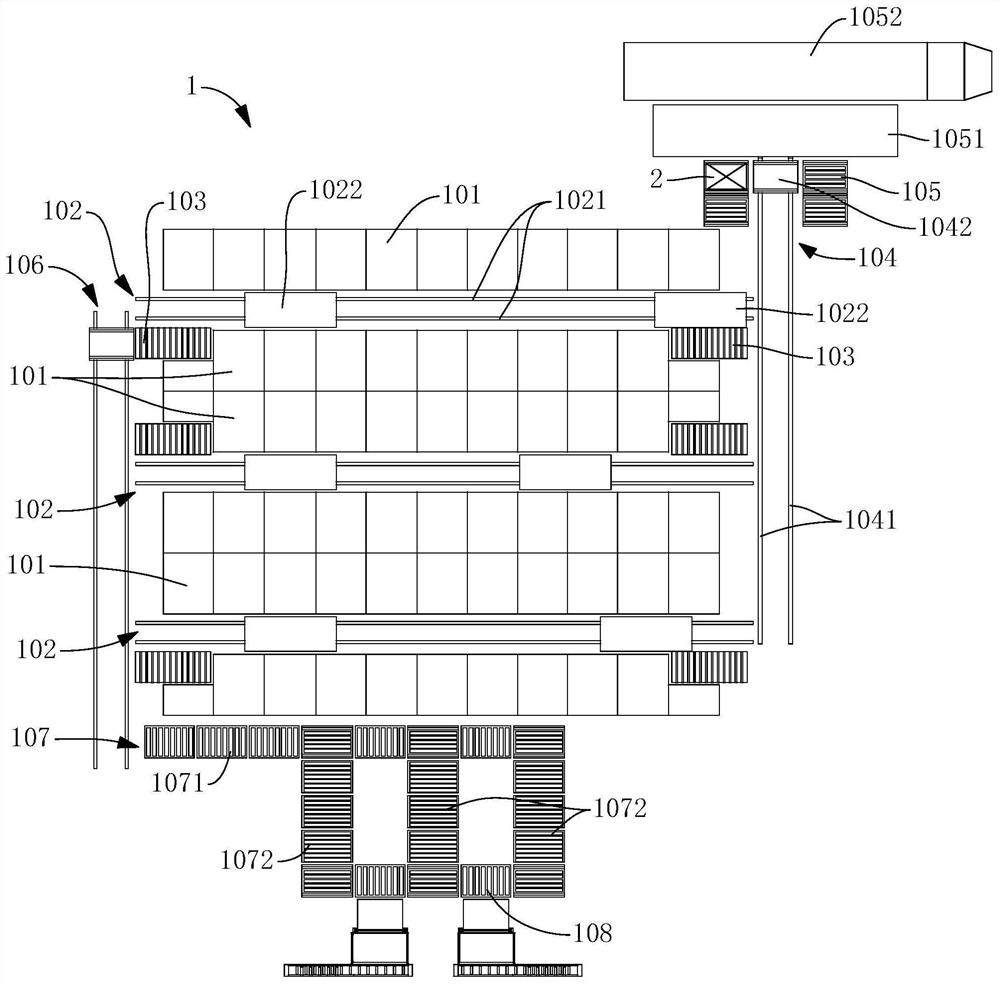

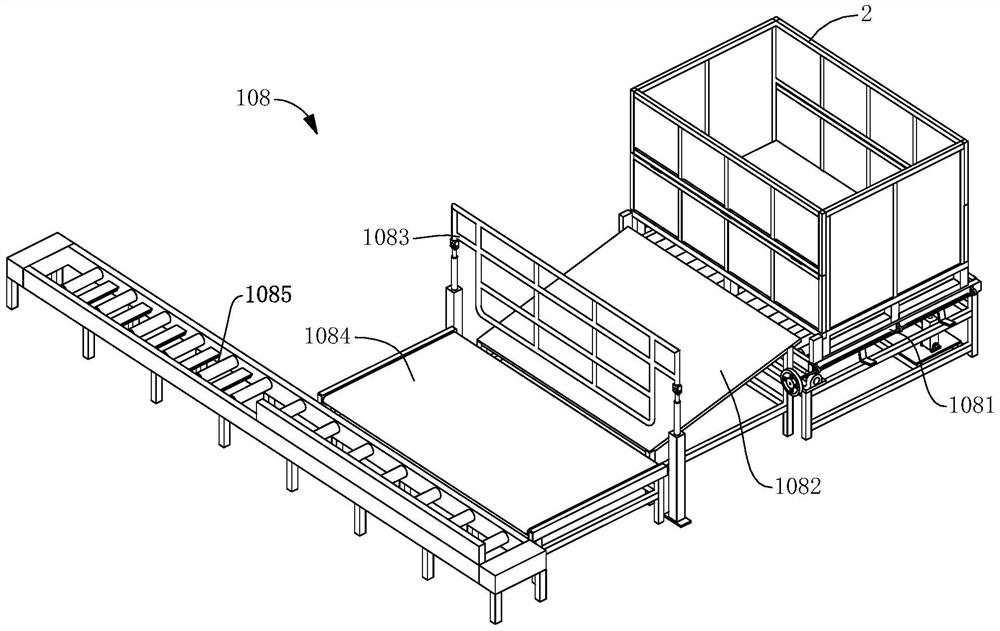

[0033] see figure 1, this embodiment provides a dyeing and finishing production system, including a gray cloth storage device 1, a turnover box 2, a loose cloth machine 3, a loose cloth buffer device 4, a gray cloth setting machine 5, a buffer device to be dyed 6, a dyeing machine 7, Circular logistics device 8 , water press buffer device 9 , water press machine 10 , finished product setting machine 11 , cloth inspection and rolling device 12 , sorting device 13 and finished product storage device 14 . The gray cloth storage device 1 is used for inputting, storing and outputting the gray clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com