Air-floatation oil removal tank for treating oil-containing waste water and oil removal method

A technology for air flotation and wastewater, which is applied in the direction of grease/oily substance/suspton removal device, separation method, flotation water/sewage treatment, etc., which can solve the problem of affecting the treatment process and cannot fully separate oily wastewater and wastewater containing dissolved oil. Deal with problems such as unsatisfactory results, and achieve full separation and degreasing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

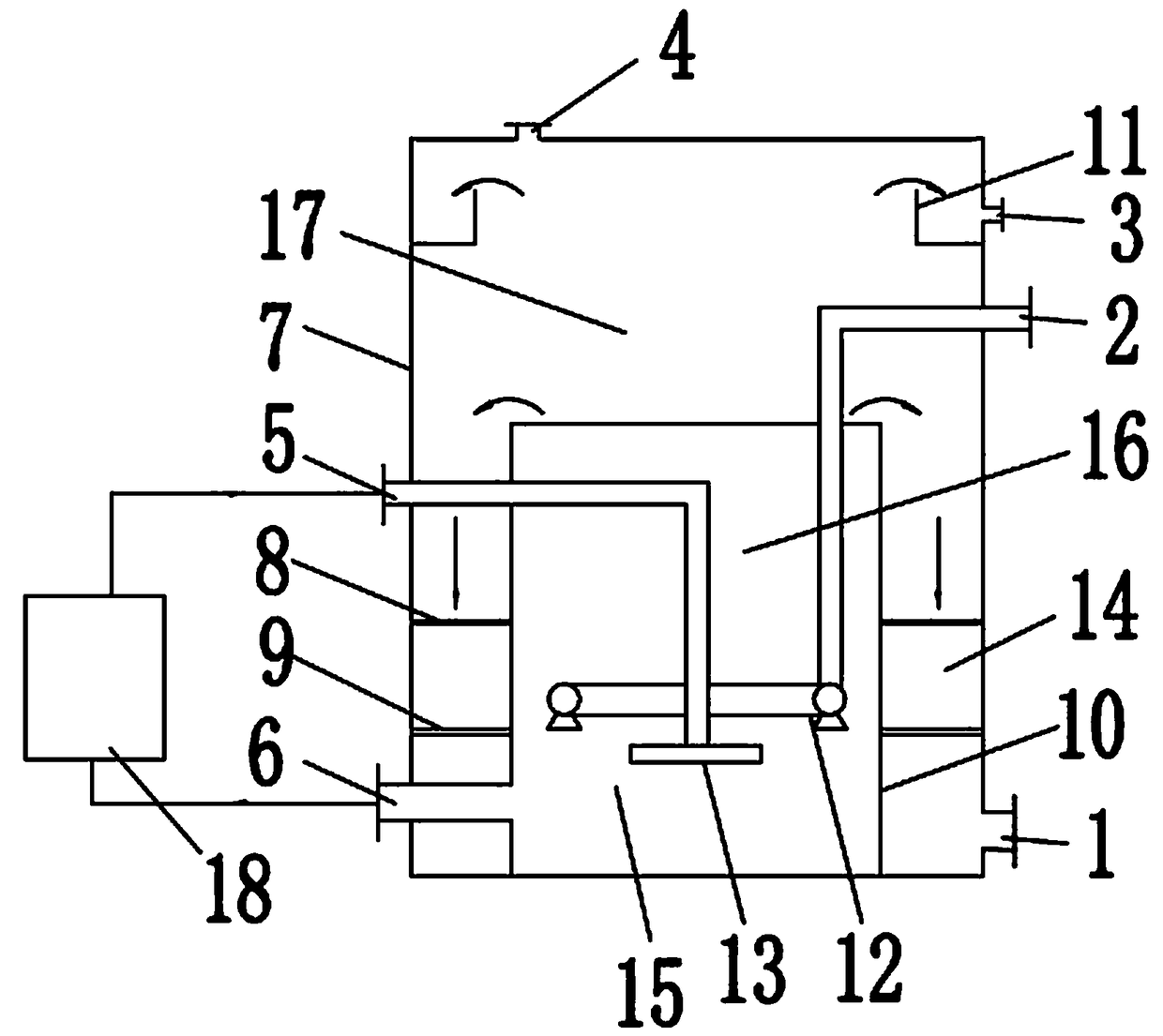

[0023] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0024] Such as figure 1 , an air flotation degreasing tank for treating oily wastewater, comprising a tank body 7, the upper part of the inner cavity of the tank body 7 is a separation zone 17, and the lower part of the inner cavity of the tank body 7 is vertically provided with a cylindrical partition 10, the partition The plate 10 divides the lower part of the inner cavity of the tank body 7 into a central air flotation area and a peripheral water outlet area; the tops of the air flotation area and the water outlet area communicate with the separation area 17;

[0025] The top of the tank body 7 is provided with an exhaust port 4;

[0026] The top of the tank body 7 is provided with an oil outlet 3, and the inner side of the oil outlet 3 is provided with an oil outlet weir 11;

[0027] The bottom of the tank body 7 is provided with a water outlet 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com