A saline-alkali soil anticorrosion foundation with enamel protection layer and its preparation method

A technology of saline-alkali soil and protective layer, applied in infrastructure engineering, roads, tracks, etc., can solve problems such as failure to prevent concrete corrosion and damage, increase costs, etc., achieve excellent alkali-resistant aggregate reaction ability, reduce voids, and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

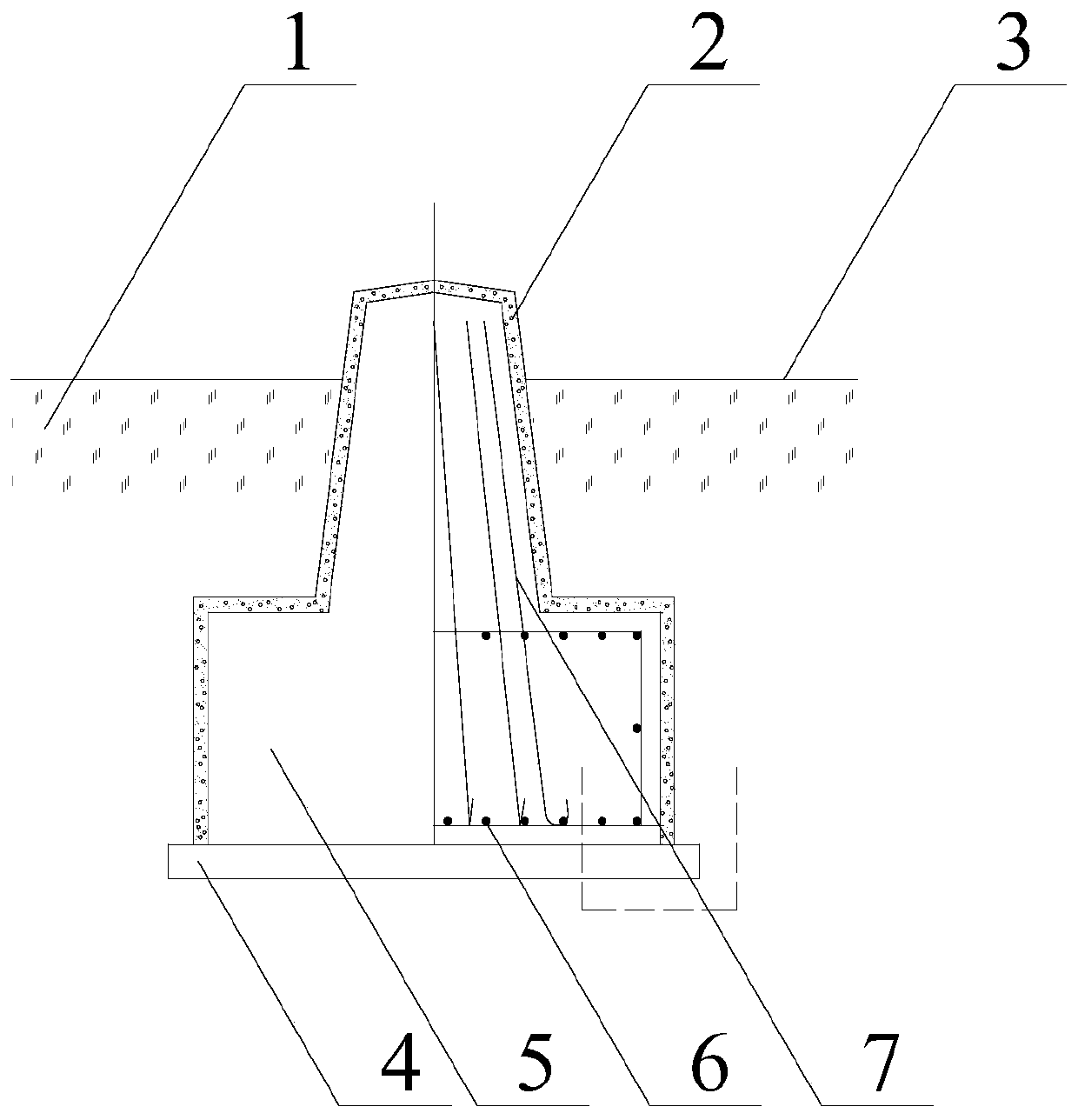

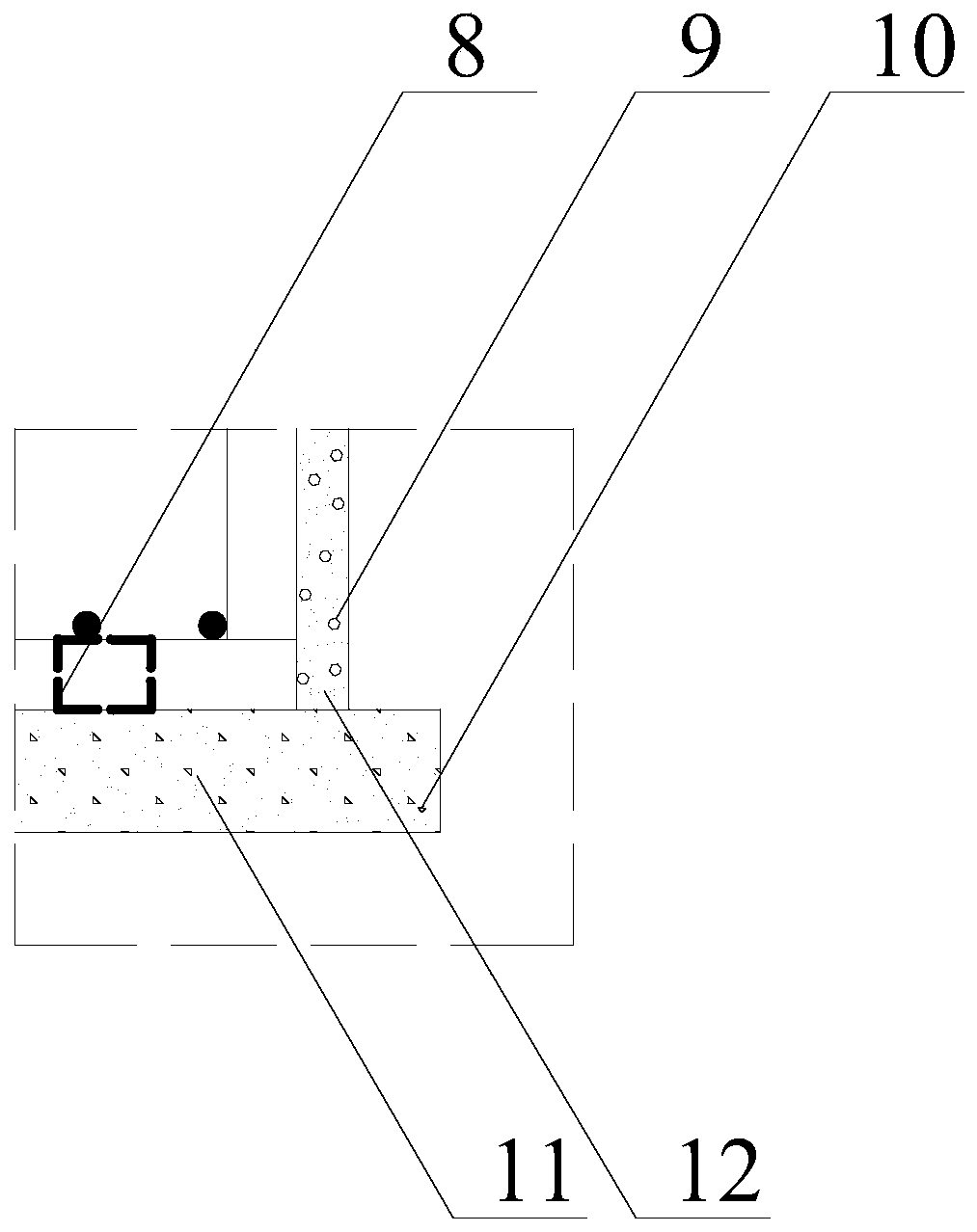

[0033] please see figure 1 with figure 2 A saline-alkali anti-corrosion foundation with an enamel protective layer provided by the present invention comprises an enamel anti-corrosion cushion 4, a reinforced concrete foundation body 5 and an enamel anti-corrosion layer 2; C20 plain concrete 11 is laid; a reinforced concrete foundation body 5 is arranged on it, and several bottom concrete pads 8 are arranged between the enamelized anti-corrosion cushion layer 4 and the reinforced concrete foundation body 5; the reinforced concrete foundation body 5 is self-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com