An electronic component and its manufacturing method

A technology of electronic components and manufacturing methods, which is applied in the direction of electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of high cost, substrate flatness, high compactness, and difficult to realize electrode production, etc., to achieve Reduce costs, improve production effects, and use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

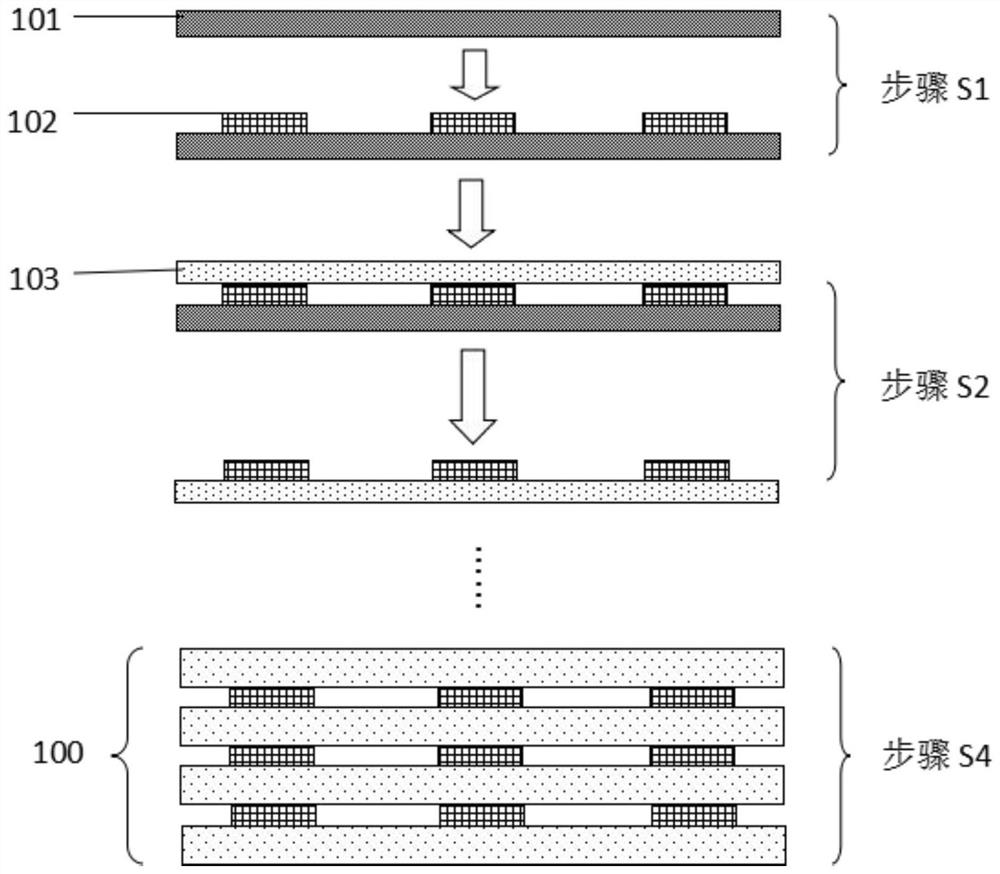

[0042] Using the manufacturing method of the above-mentioned electronic components to manufacture metric 0806 laminated chip common mode inductors includes the following steps: using organic thin film transfer electrodes, transferring the fine electrodes to the inorganic thin film substrates, laminating them to form ceramic green bodies, and then Cutting, debinding, sintering, chamfering, making terminal electrodes and electroplating are sequentially completed on the ceramic green body to complete the production of electronic components. specifically:

[0043] 1) making conductive electrodes on the organic film substrate;

[0044] 1.1) Prepare the organic film substrate

[0045] Purchase PANAC's TP-01 release transfer film.

[0046] 1.2) Making conductive electrodes

[0047] 1.2.1) Equipped with conductive paste: the silver paste of L6112 produced by Dupont Company, with a volume resistivity of 0.022mm*ohm;

[0048] 1.2.2) Use screen printing equipment to coat the conducti...

example 2

[0063] The metric 0806 multilayer chip common mode inductor is produced by the above-mentioned manufacturing method of electronic components. The difference between the steps and the example 1 is that step 2.3) is: use 300-800mJ / cm for the bonded substrate 2 The UV light is used for illumination; step 2.4) is: after the above UV illumination is completed, the organic film is torn off, and at this time the electrode has been transferred to the inorganic film substrate. Among them, the metric 0806 multilayer chip common mode inductor, the line width and line spacing can also be reduced by 50% compared with the traditional yellow light process. A drop of 30% to 35%.

example 3

[0065] Manufacturing metric 0605 multilayer chip common mode inductors by using the manufacturing method of the above-mentioned electronic components includes the following steps: transferring the fine electrodes to the inorganic thin film substrate by means of organic thin film transfer electrodes, performing lamination to form a ceramic green body, and then Cutting, debinding, sintering, chamfering, making terminal electrodes and electroplating are sequentially completed on the ceramic green body to complete the production of electronic components. specifically:

[0066] 1) making conductive electrodes on the organic film substrate;

[0067] 1.1) Prepare the organic film substrate

[0068] Purchase PANAC's TP-01 release transfer film.

[0069] 1.2) Making conductive electrodes

[0070] 1.2.1) Equipped with conductive paste: L6112 silver paste produced by Dupont Company, with a volume resistivity of 0.022mm*ohm;

[0071] 1.2.2) The conductive electrode paste is coated on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com