A method for measuring interface fluctuation of molten aluminum

A technology of aluminum liquid and interface, which is applied in the field of aluminum electrolysis, can solve the problems of damaging the thermal stability of the electrolytic cell, roughness, and large power consumption of the electrolytic cell, and achieves the goal of overcoming the fluctuation of the aluminum liquid interface, overcoming the low precision, and realizing soft measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with examples.

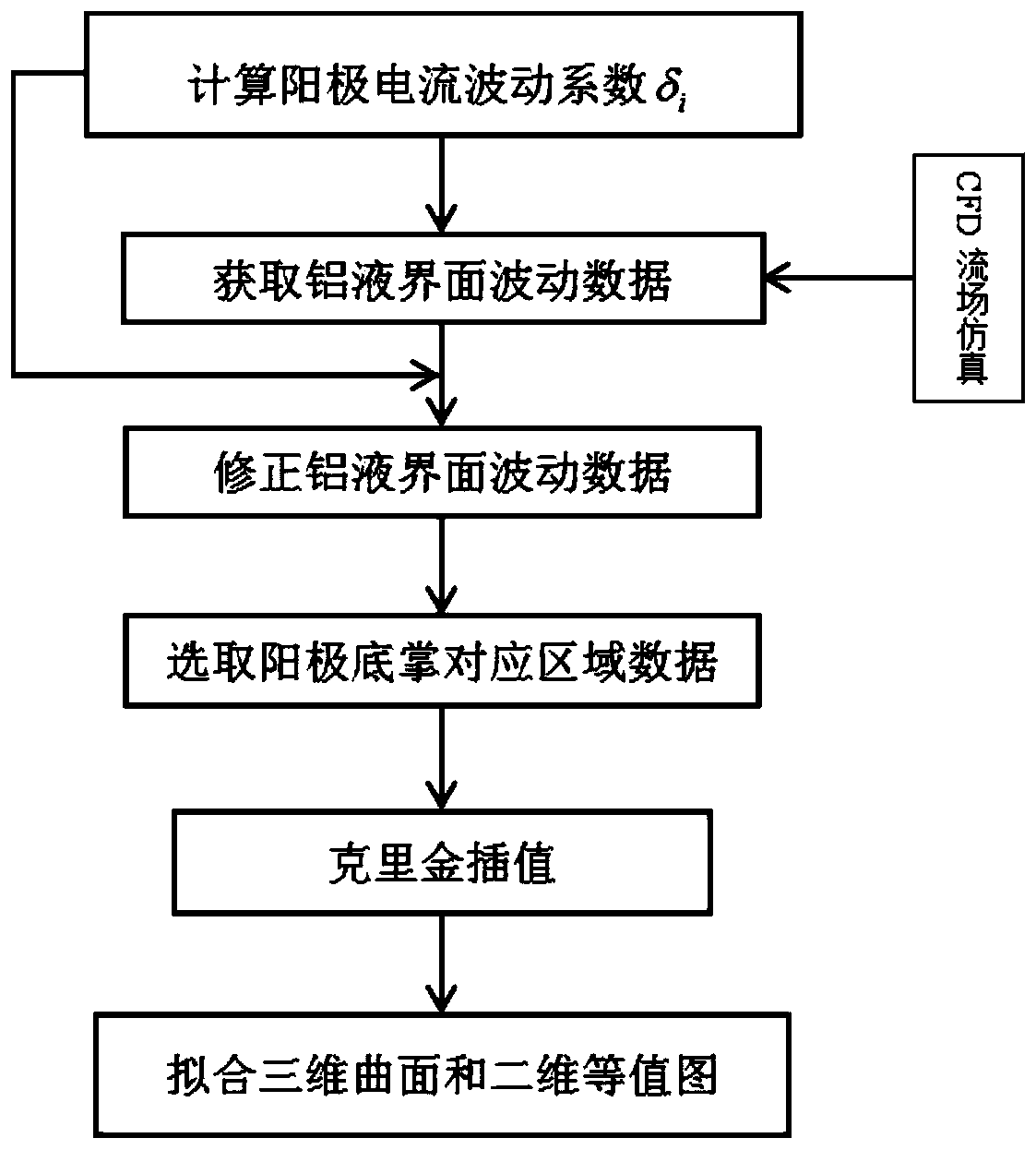

[0058] Such as figure 1 As shown, the embodiment of the present invention provides a method for measuring the interface fluctuation of molten aluminum, comprising the following steps:

[0059] Step 1: Collect the anode current of each anode in the aluminum electrolytic cell, and calculate the anode current fluctuation coefficient of each anode.

[0060] Among them, the anode current of each anode is collected by a non-contact measurement method. And calculate the anode current fluctuation coefficient of each anode according to the following formula:

[0061]

[0062] In the formula, δ i is the anode current fluctuation coefficient of the i-th anode, I i is the collected anode current of the i-th anode, I is the preset series current, and m is the number of anode blocks in the electrolytic cell. For example, the electrolytic cell selected in this embodiment has 48 anodes in tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com