Android-based numerically-controlled machine tool machining state real-time monitoring method

A technology for CNC machine tools and machine tool status, applied in the industrial field, can solve the problems of lathe information monitoring, lack of mobility and portability on the PC side, and difficulties for workshop operators to monitor the running status of CNC machine tools anytime and anywhere, and achieve simple broadband wiring structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further describe the technical features and effects of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

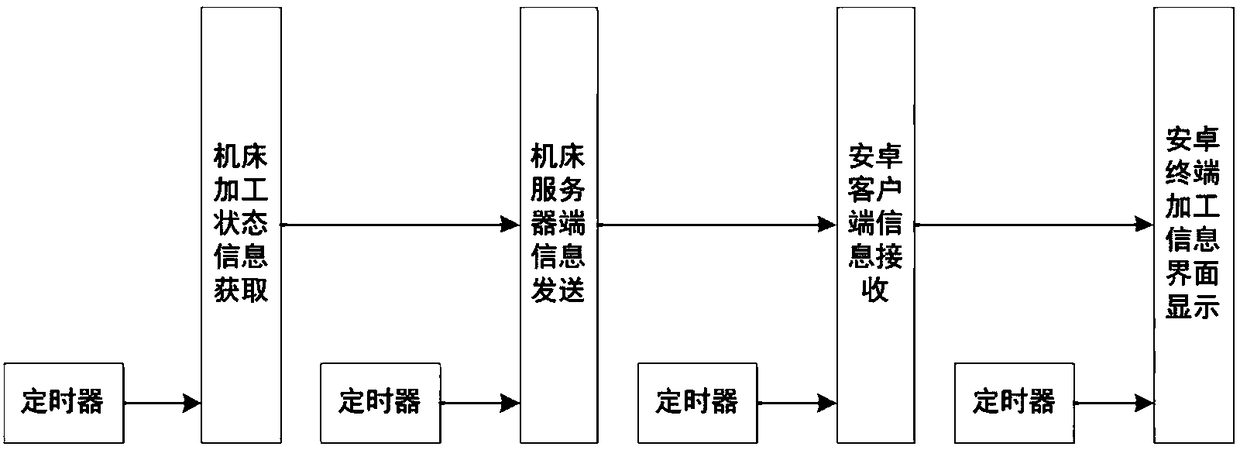

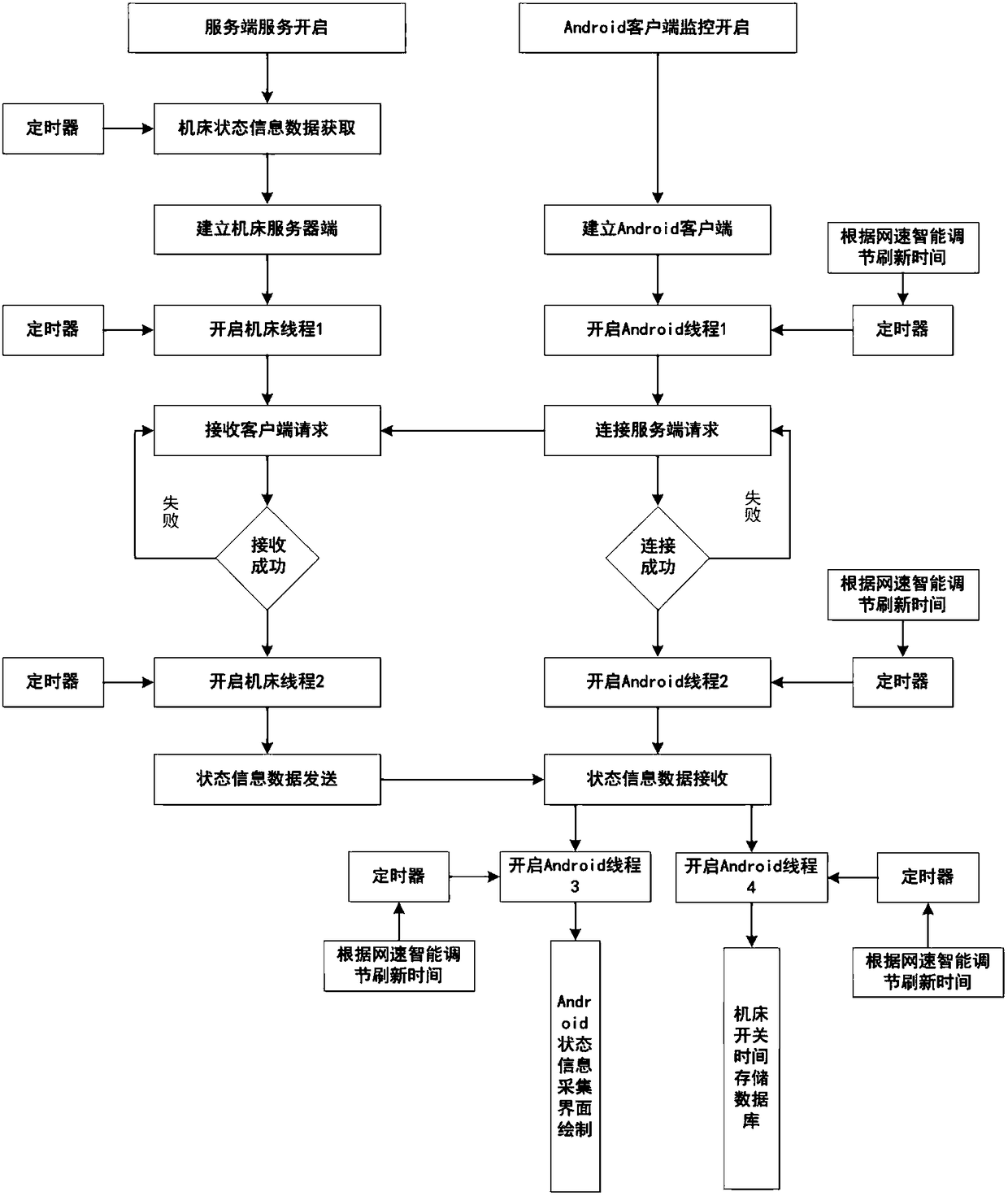

[0024] like Figure 1-Figure 4 As shown, an Android-based real-time monitoring method of CNC machine tool processing status, the overall process is as follows figure 1 Shown:

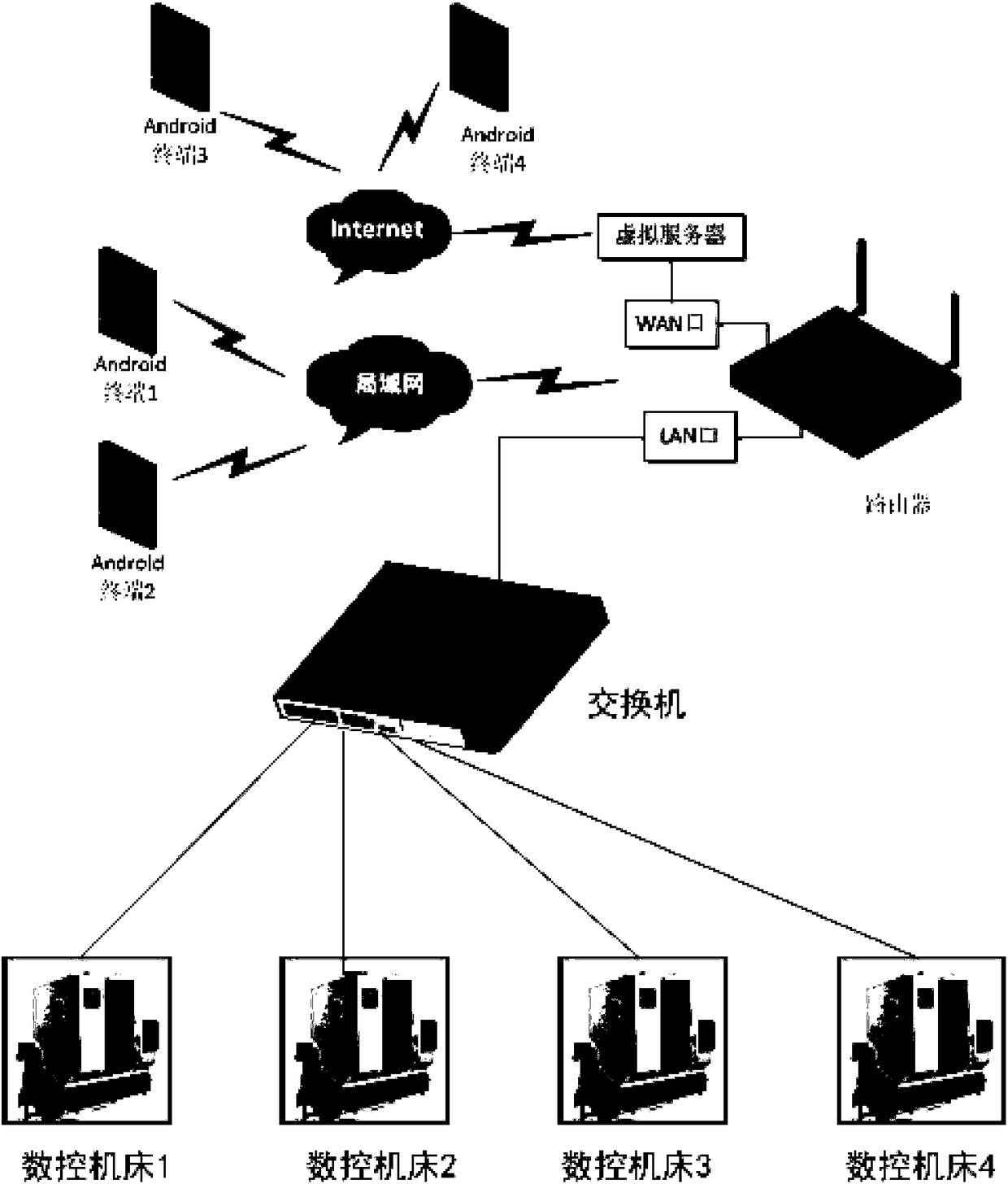

[0025] The first step is to obtain the machine tool state information data during the operation of the CNC system, including the X, Z, and C three-axis workpiece command position, the machine tool command position, the actual position of the machine tool, the actual speed, the motor speed, the feed rate F of the machine tool, and the machine tool spindle Speed S, and then convert the basic information data of each axis into a string data type and store it in a string array. Using socket communication, multiple sockets are established on the server side of the machine tool, one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com