Improved bridge deck laying device

A laying device and technology for bridges, applied in bridge construction, bridges, bridge parts, etc., can solve the problems of reducing the efficiency of bridge deck laying, increasing the work process, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

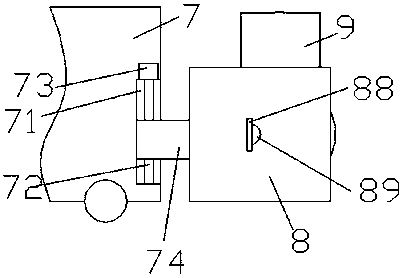

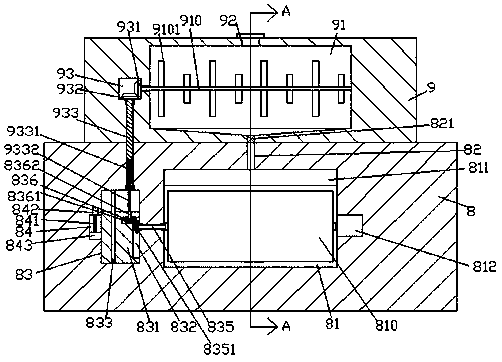

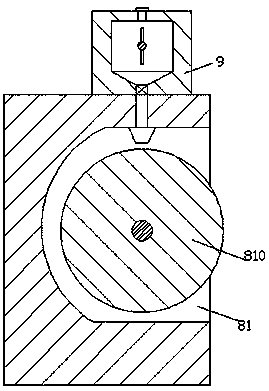

[0015] Such as figure 1 , figure 2 and image 3 As shown, an improved bridge deck laying device of the present invention includes a driving body 7 and a laying frame installed on the front end of the driving body 7, and the front end surface of the driving body 7 is provided with an up and down extension The lifting groove 71 is provided, and the lifting block 74 is connected with sliding fit in the lifting groove 71, and the main screw-shaped rod 72 extending up and down is connected in the internal spiral fit of the lifting block 74, and the front side end of the lifting block 74 is transparent. Out of the driving body 7 and fixedly connected with the rear end surface of the lower frame 8, the top extension tail of the main screw rod 72 is connected with the lifting groove 71 in rotation, and the bottom of the main screw rod 72 The extension tail is connected with the main driving machine 73, and the outer surface of the main driving machine 73 is installed in the inner b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com