Large-angle universal crushing hammer

A universal, large-angle technology, applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of angle limitation of the working range, failure to work, loosening and misalignment, etc., and achieve increased The effect of working range angle, simple structure and stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments.

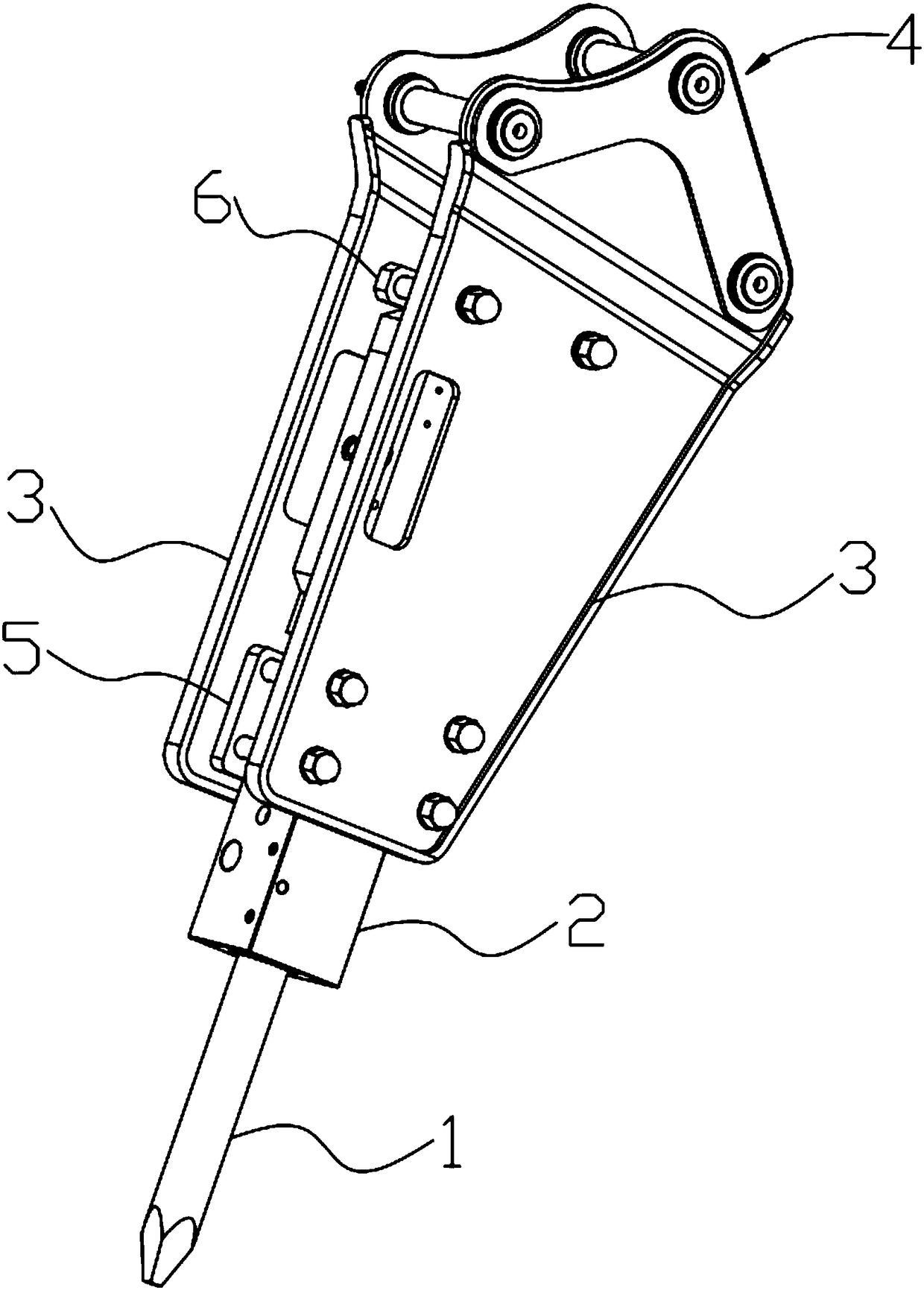

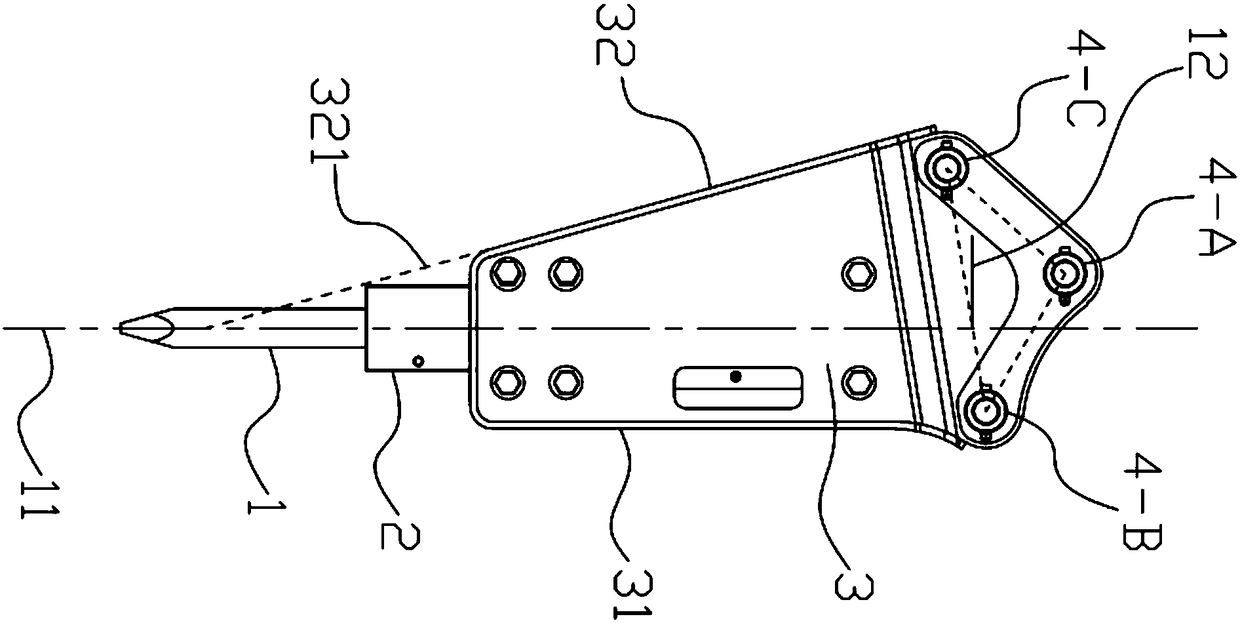

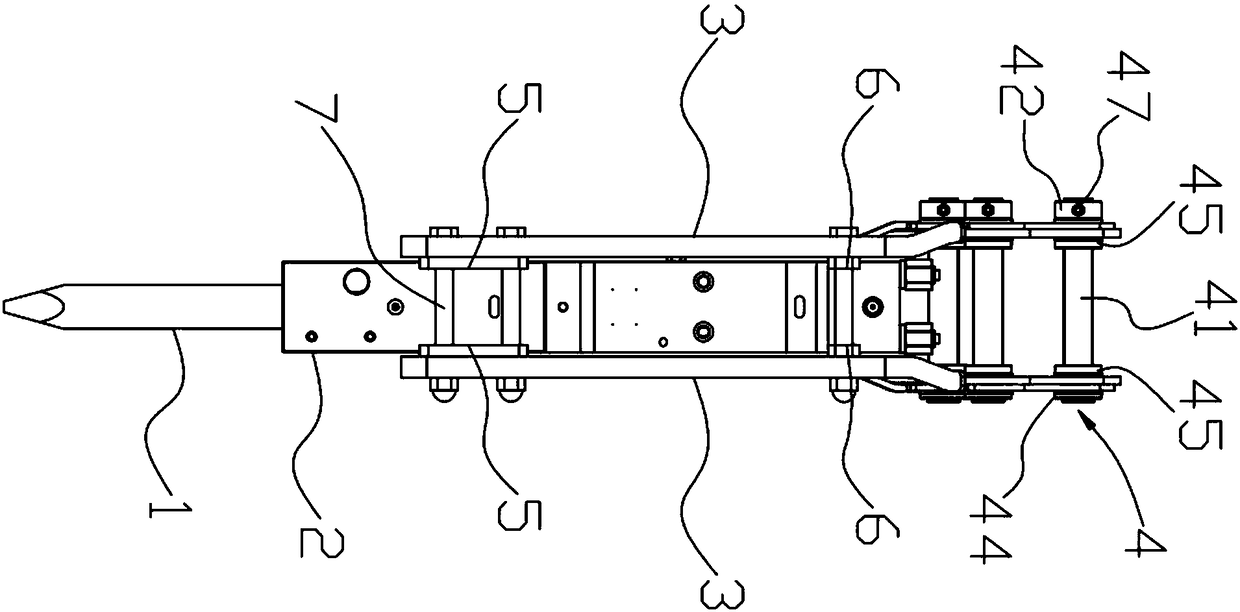

[0024] Such as Figures 1 to 3 As shown, the large-angle universal breaker of the present invention is connected with the excavator 100 or other working machines when in use, and is used in construction to break rocks, concrete or some other relatively hard materials. In this embodiment, the large-angle universal breaking hammer includes a crushing tip 1, a hammer body 2 connected to the crushing tip 1, and guard plates 3 fixed on both sides of the hammer body 2, and the guard plates 3 on both sides are symmetrically arranged on the left and right sides of the hammer body 2 On both sides, the crushing tip 1 is exposed at the front end of the guard plate 3, and the rear ends of the guard plates 3 on both sides are provided with three sets of pin shaft assemblies 4 distributed in a triangle. The three groups of pin assemblies 4 are respectively pin assembly A (4-A), pin asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com