Construction method for soft surrounding rock section at tunnel portal passing through fine sand layer

A technology with weak surrounding rocks and construction methods, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as tunnel entry difficulties in sand layers, achieve the effects of controlling sand layer hazards, ensuring construction safety, and reducing disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

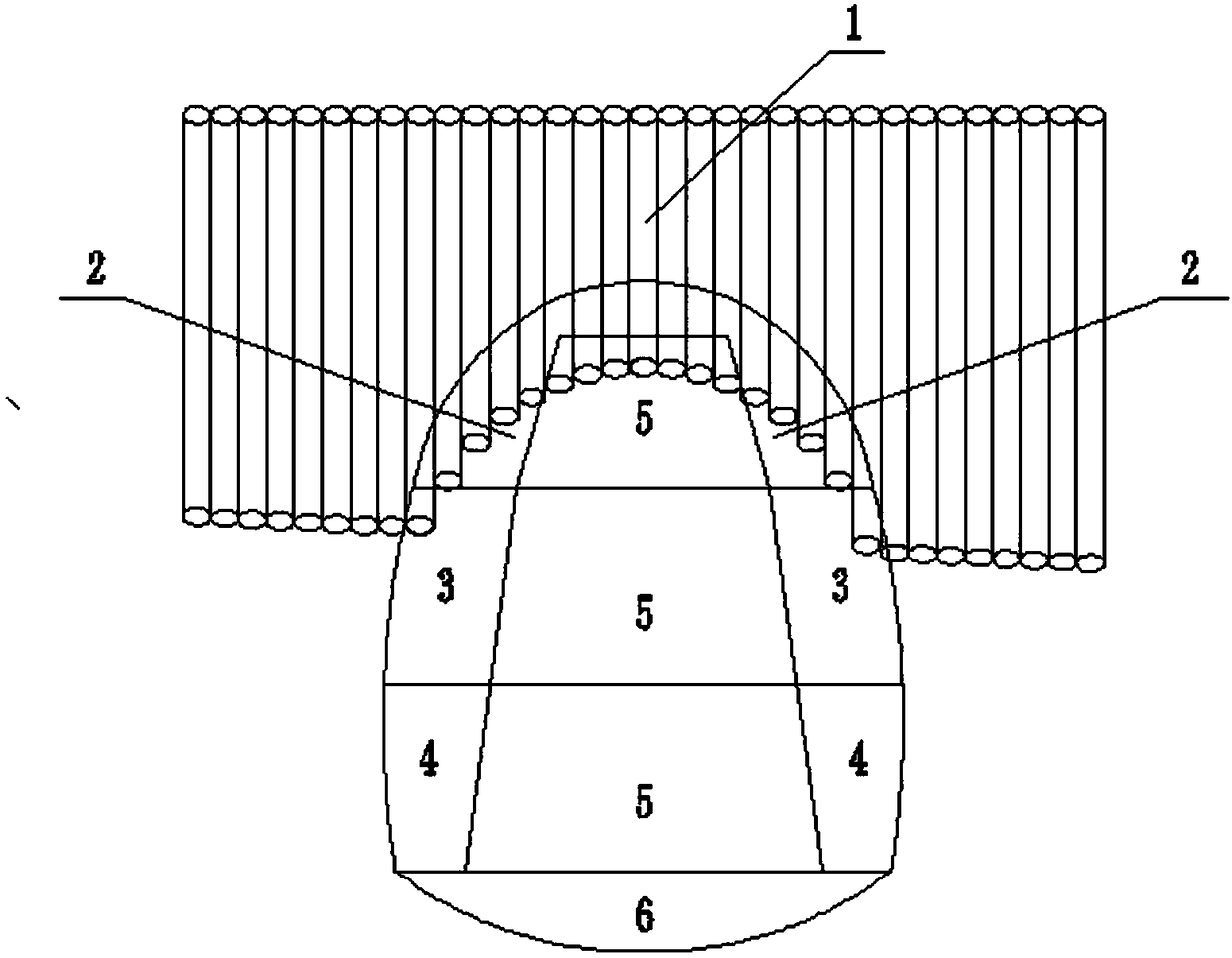

[0028] like figure 1 Shown, the construction sequence of the present invention:

[0029] The present invention includes 6 working faces, and the construction sequence of each working face is detailed in figure 1 , where, firstly, the high-pressure jet grouting pile 1 is applied outside the tunnel, and then excavated according to the order of the top arc-shaped pilot pit 2, the middle steps on the left and right sides 3, the lower steps on the left and right sides 4, the reserved core soil 5, and the tunnel bottom 6 , the operation method of each division is as follows:

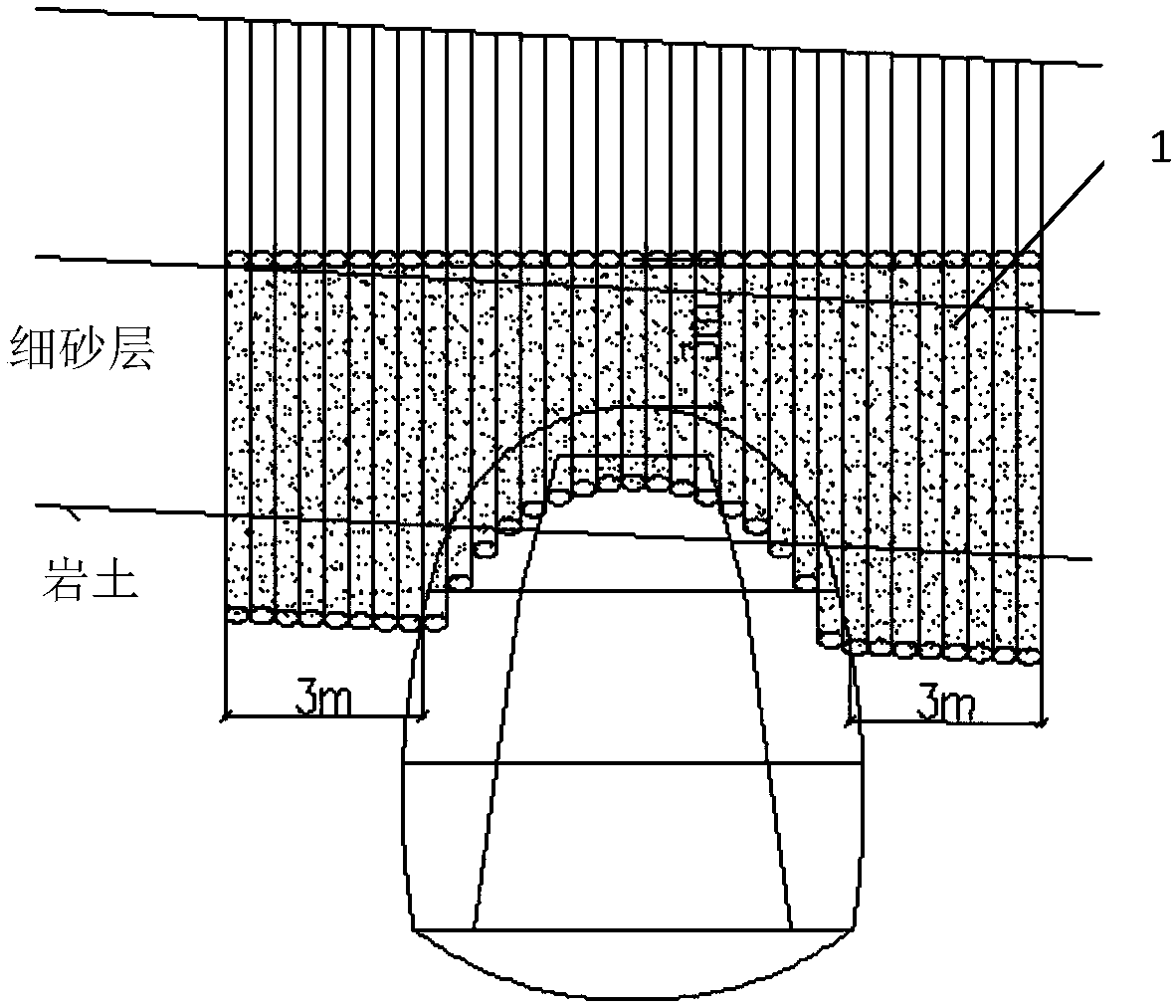

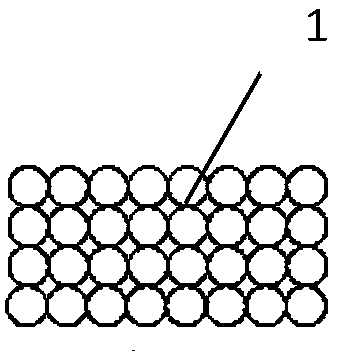

[0030] (1) if figure 2 As shown, the high-pressure rotary grouting piles 1 outside the tunnel are constructed: several vertical high-pressure rotary grouting piles 1 are constructed above the tunnel entrance, and the high-pressure rotary grouting piles 1 penetrate from top to bottom to within the tunnel excavation contour. Preferably, the vertical high-pressure jet grouting piles 1 outside the hole adopt a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com