Blade tip extension connecting structure and assembling method thereof

A technology of extending connection and blade tip, applied in the field of blade tip extension connection structure and its assembly, can solve the problems of excessively long glued surface, unfavorable construction, poor structural strength and stability, etc., to improve stress concentration, improve reliability, Guaranteed effect of continuous distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

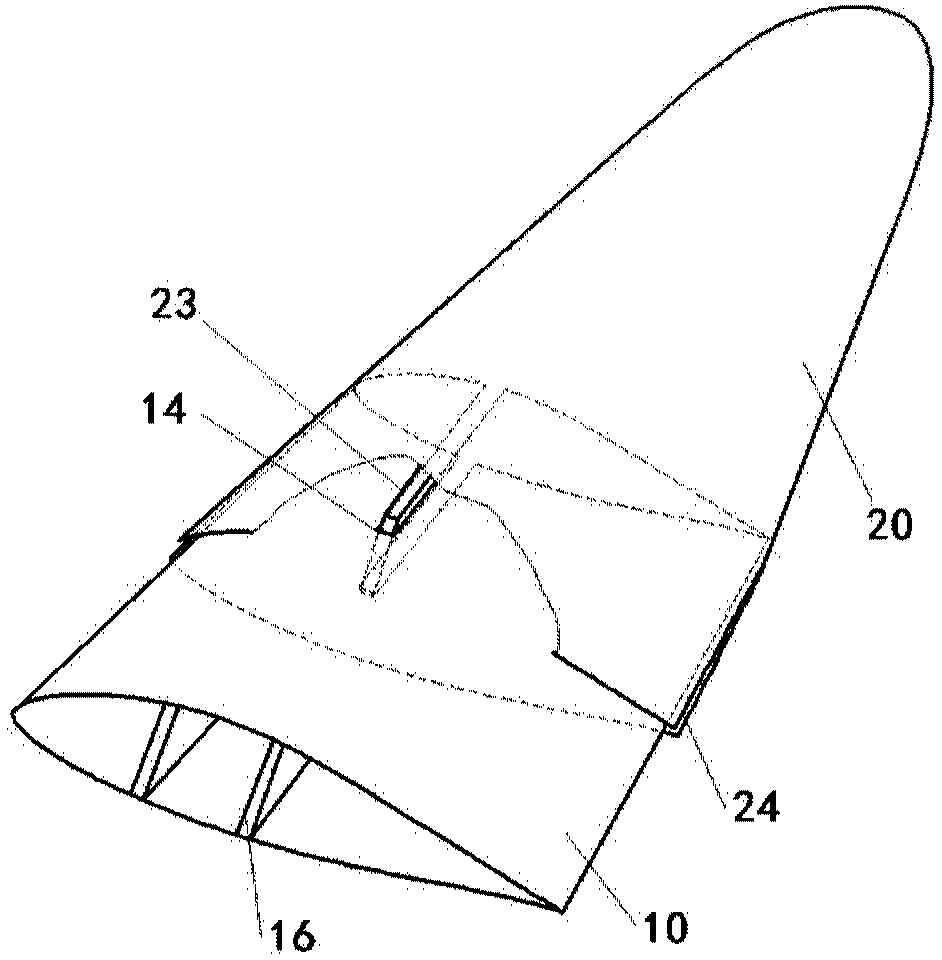

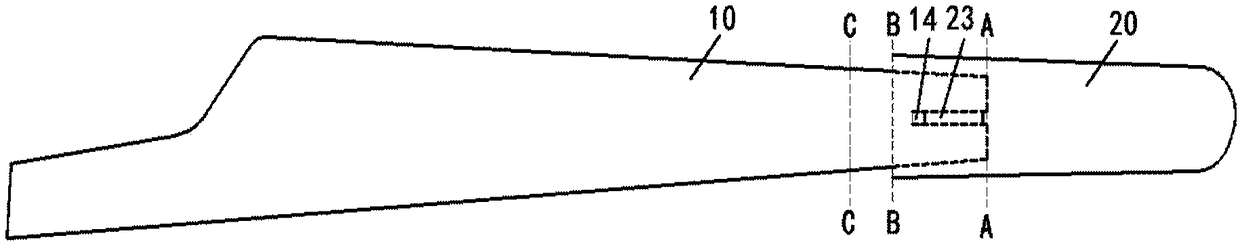

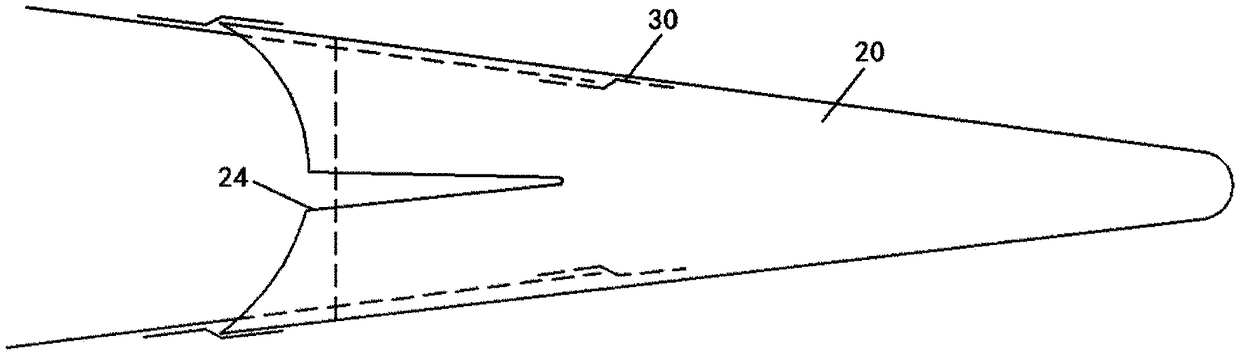

[0046] The present disclosure provides a blade tip extension connection structure and an assembly method thereof. The blade root section and the blade tip section are connected by glue; the blade root section is the residual structure after cutting off the tip part of the original blade, and the blade tip section is a newly manufactured structure. Along the span direction, the blade root section is composed of the complete blade root section, the blade root reinforcement section and the blade root bonding section. The blade tip segment is composed of the blade tip bonding segment and the blade tip intact segment along the spanwise direction. The blade root section has a spanwise connecting notch from the outermost section inward on the pressure surface and suction surface, the blade tip section is provided with a connecting web, the blade root section is nested in the blade tip section, and the connection of the blade root section The notch is aligned with the connecting web ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com