Water-boiling-resistant essence and preparation method thereof

A technology that is resistant to boiling and flavoring flavors, applied in the field of flavors, can solve the problems of structural damage of wall materials, failure to achieve the expected effect in the field of cooking applications, and easy volatilization, so as to achieve the effect of ensuring continuous emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

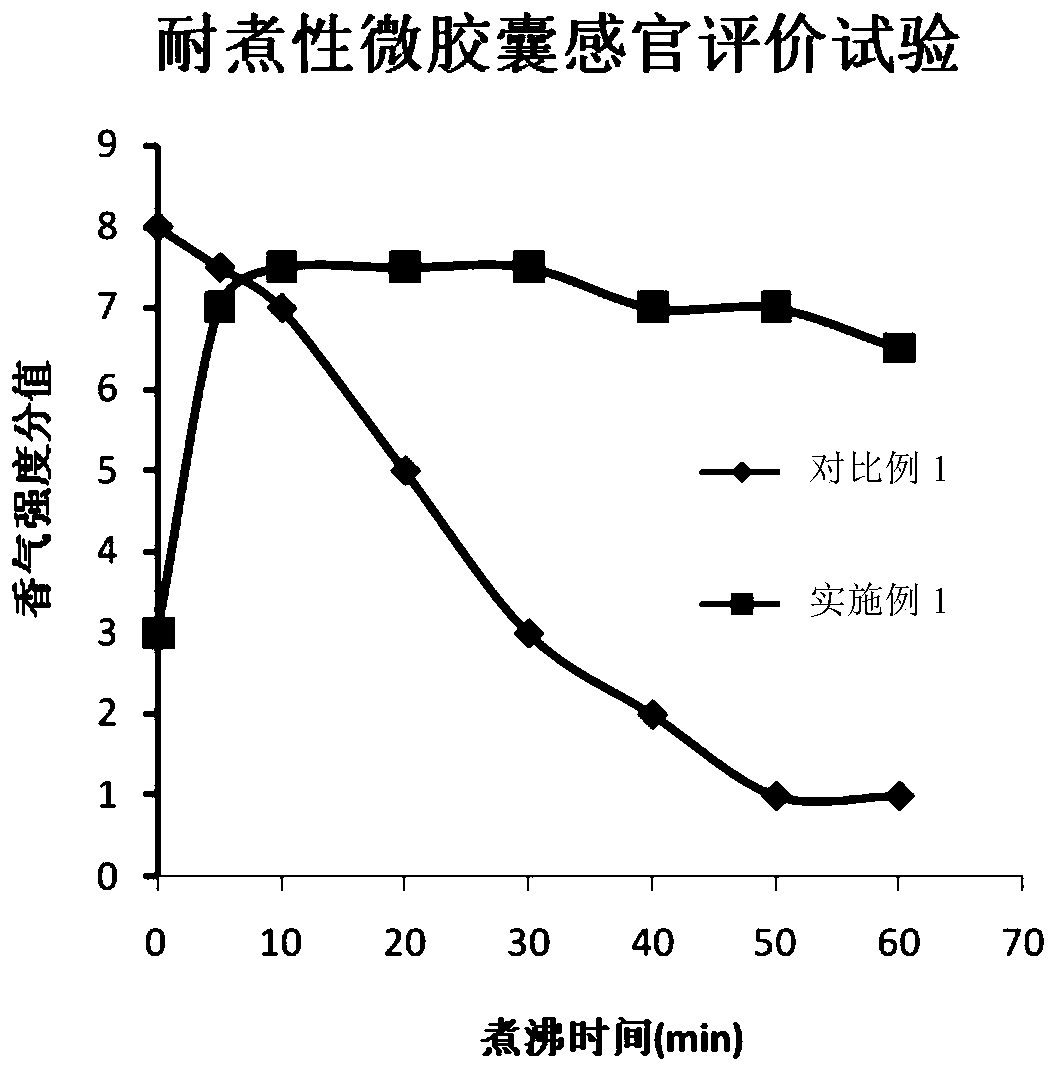

Examples

Embodiment 1

[0024] A boiling-resistant flavor, which is made of the following raw materials in parts by weight: 5 parts of peppery meat flavor base, 20 parts of sucrose, 35 parts of tapioca starch, 29.9 parts of water, 10 parts of maltodextrin, sucrose fatty acid ester 0.1 part.

[0025] The peppery meat flavor base includes the following components: green pepper oleoresin 1%; 2-mercapto-3-butanol: 0.2%; 2-methyl-3-mercaptotetrahydrofuran: 0.2%; 2-methyl-3 -Mercaptofuran: 0.2%; 3-Mercapto-2-butanone: 0.2%; 4-methyl-5-hydroxyethylthiazole: 0.1%; Mercaptofuran acetate: 0.1%; Cinnamon oil: 0.6%; Fennel Oil: 0.5%; Ginger Oil: 0.5%; Furfural: 0.2%; Furanone: 0.1%; 2-Acetylpyrazine: 0.1%; Salad Oil: 96%.

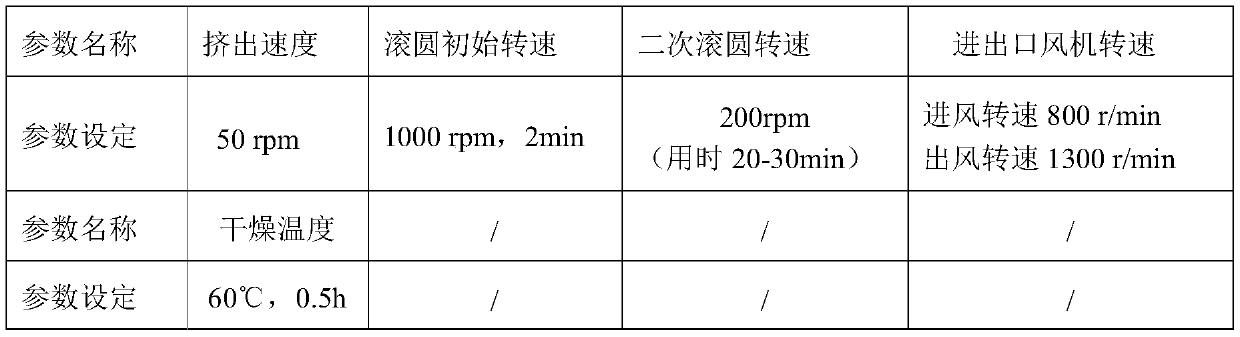

[0026] The preparation method of described boil-resistant type essence, comprises the steps:

[0027] (1) Mix the peppery meat flavor base with tapioca starch and maltodextrin evenly;

[0028] (2) Add sucrose into water, after all of it is dissolved, heat and boil, then pour the material p...

Embodiment 2

[0033] A boiling-resistant flavor, which is made of the following raw materials in parts by weight: 6 parts of trimethylthiopropionaldehyde, 20 parts of microcrystalline cellulose, 40 parts of tapioca starch, 20 parts of sucrose, 13.8 parts of water, sucrose fatty acid glyceride 0.2 parts.

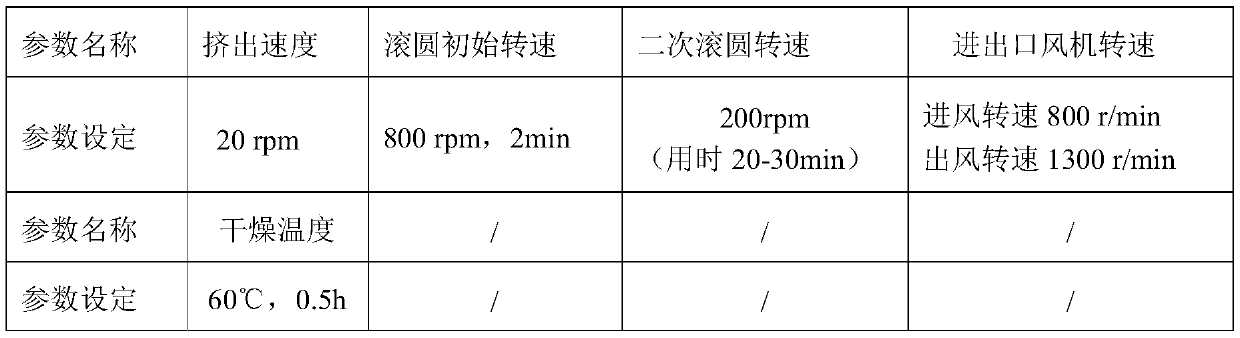

[0034] The preparation method of described boil-resistant type essence, comprises the steps:

[0035] (1) Trimethylthiopropionaldehyde is mixed with tapioca starch and microcrystalline cellulose;

[0036] (2) Add sucrose into water, after all of it is dissolved, heat and boil, then pour the material prepared in step (1), add sucrose fat monoglyceride, stir and mix for 10-15min to obtain soft material;

[0037] (3) Send the soft material into the extruder, then send the extruded material into the tumbling plate for spheronizing and drying, seal it with a bag immediately after granulation, and place it in a refrigerator at -4°C Save, the specific setting parameters are shown in Table 2.

...

Embodiment 2

[0058] Embodiment 2 and comparative example 2 are carried out the physicochemical determination of resistance to cooking:

[0059] Physical and chemical detection method:

[0060] (1) Extraction of 3-methylthiopropanal

[0061] Accurately draw 1mL of the cooking solution containing 3-methylthiopropanal, put it in a 5mL centrifuge tube, add 2mL of ether, shake it in a vortex shaker for 30s, let it stand for stratification, absorb 1mL of the supernatant, And add 0.5g of anhydrous sodium sulfate to shake, and pass through the membrane (0.22um organic filter membrane), which is the solution to be tested;

[0062] (2) GC-MS detection of 3-methylthiopropanal

[0063] Put the liquid to be tested in step (1) in a dry headspace bottle, tighten the sealing cap, and preheat at the set sampling temperature for 10 minutes, then absorb and sample the extraction head, the sampling temperature is 100°C, and the sampling time is 51 minutes. Then injected into GC-MS for detection, analysis f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com