Environment-friendly compound printing ink

An environmentally friendly ink technology, applied in ink, household utensils, applications, etc., can solve the problems of difficult to meet the standard of harmful solvent residues, health hazards of operators, poor versatility, etc., achieve excellent adhesion fastness, and meet the requirements of water boiling resistance , Good for environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

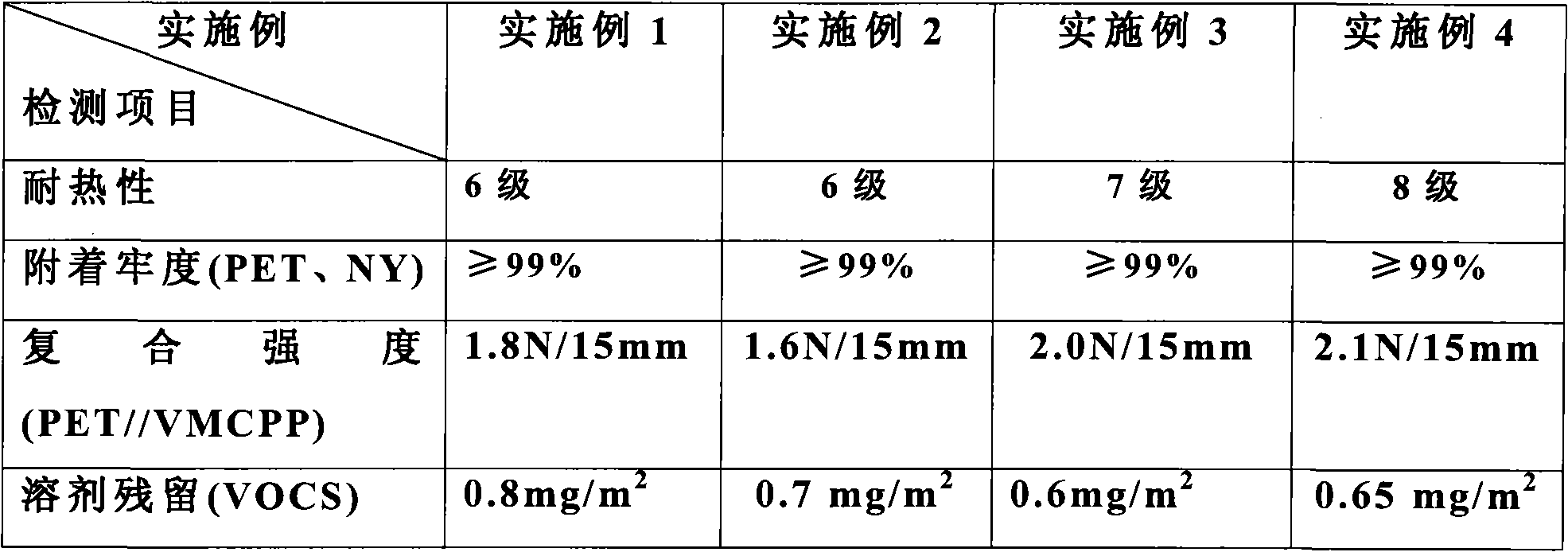

Examples

Embodiment 1

[0015] See Table 1 according to the composition of the environment-friendly composite ink of the present embodiment:

[0016] Table 1

[0017] components

Content (wt%)

Polyamide resin (number average molecular weight 4000)

18

EVA (number average molecular weight 20000)

12

Organic Phthalocyanine Blue Pigment

10

Absolute ethanol (industrial grade)

58

n-propanol

2

[0018] Composite ink is prepared from various raw materials through the following steps:

[0019] (1) Preparation of standby color paste: about 48g polyamide resin, 40gEVA, 72g solvent (dehydrated alcohol: ethanol mass ratio 29: 1) and 40g organic phthalocyanine blue pigment are dropped into the mixing tank, and stirred on a high-speed mixer for 15- After 30 minutes, grind and disperse in a sand mill until the fineness reaches below 5 microns, make up the solvent volatilized during the grinding process to obtain a spare color paste; ...

Embodiment 2

[0022] See Table 2 according to the composition of the environment-friendly composite ink of the present embodiment:

[0023] Table 2

[0024] components

Content (wt%)

Polyamide resin (number average molecular weight 6000)

18

EVA (number average molecular weight 20000)

12

organic red pigment

10

Absolute ethanol (industrial grade)

60

[0025] Composite ink is prepared from various raw materials through the following steps:

[0026] (1) Preparation of spare color paste: put about 48g of polyamide resin, 40g of EVA, 72g of absolute ethanol and 40g of organic red pigment into the mixing tank, stir on a high-speed mixer for 15-30 minutes, and then grind and disperse on a sand mill. When the fineness reaches below 5 microns, make up the solvent to get the spare color paste;

[0027] (2) Prepare composite ink: put about 12g of polyamide resin, 4g of EVA, 100g of spare color paste obtained in step (1), and 84g o...

Embodiment 3

[0029] See Table 3 according to the composition of the environment-friendly composite ink of the present embodiment:

[0030] table 3

[0031] components

Content (wt%)

Polyamide resin (number average molecular weight 8000)

18

EVA (number average molecular weight 10000)

12

organic yellow pigment

10

Absolute ethanol (industrial grade)

58

n-propanol

2

[0032] Composite ink is prepared from various raw materials through the following steps:

[0033] (1) Prepare spare color paste: put about 48g polyamide resin, 40g EVA, 72g solvent and 40g organic yellow pigment into the mixing tank, stir on a high-speed mixer for 15-30 minutes, then grind and disperse on a sand mill, and wait until the fineness When it reaches below 5 microns, make up the solvent to get the spare color paste;

[0034] (2) Prepare composite ink: put about 12g of polyamide resin, 4g of EVA, 100g of spare color paste obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com