Laser microtexturing self-lubricating method for variable-pitch/yaw bearing in wind turbine generator system

A technology for wind turbines and yaw bearings, applied to ball bearings, bearing components, shafts and bearings, etc., can solve problems such as discounting of lubrication effects, achieve the effects of reducing friction and wear, avoiding failure, and reducing initial roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

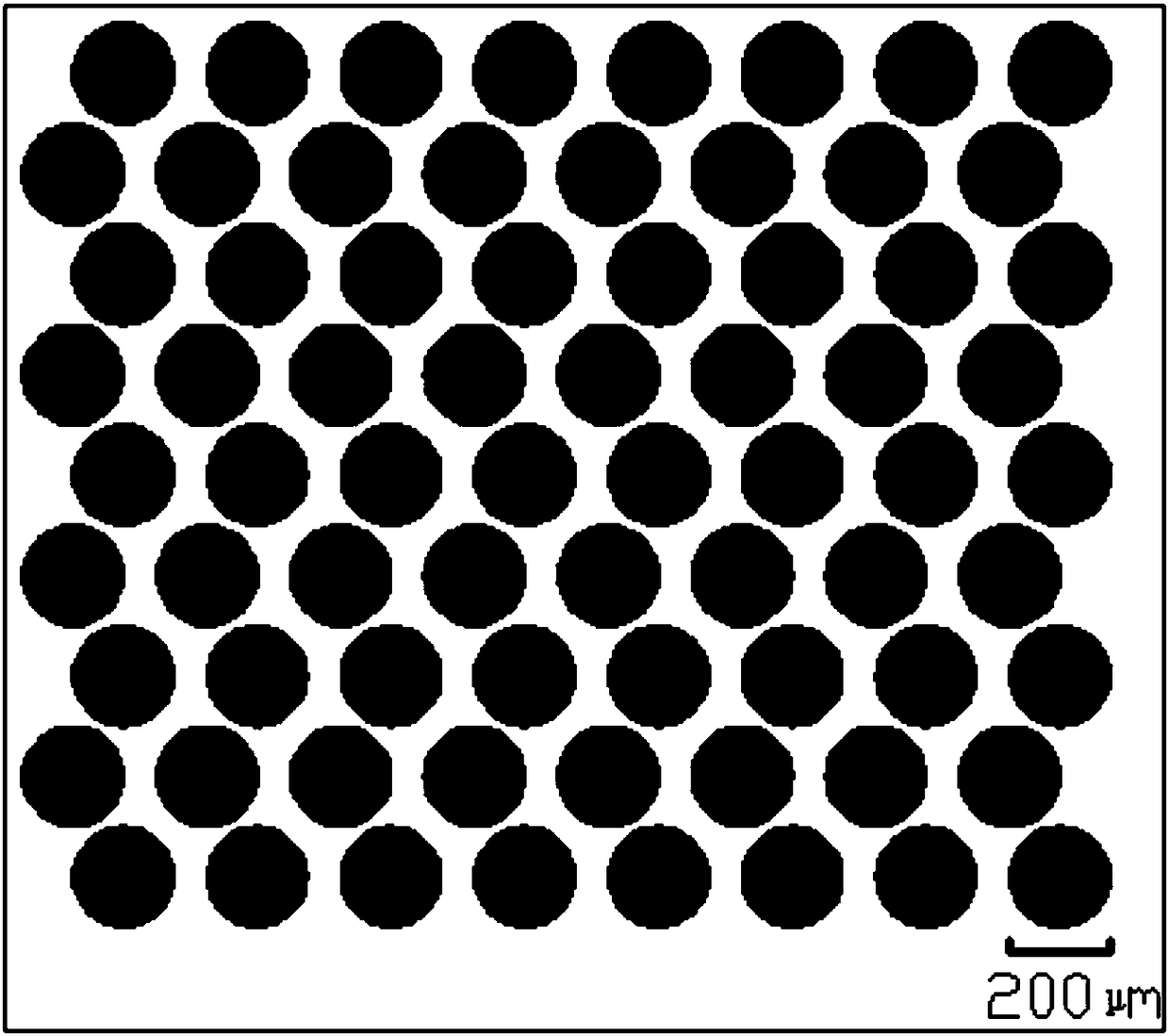

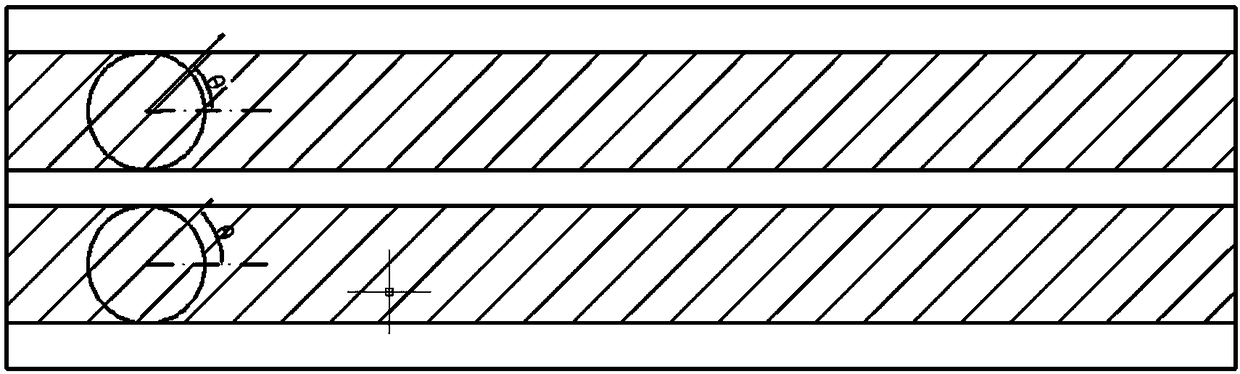

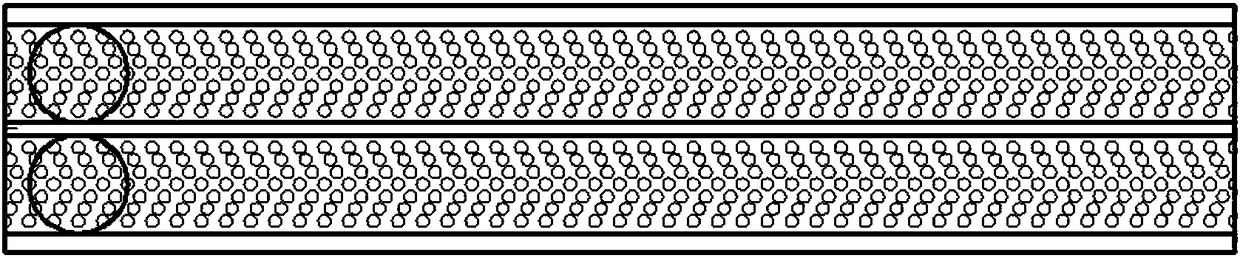

[0036] The ideal circular pits are obtained by laser micro-texturing on the surface of the laser-hardened raceway and the surface of the ball. The microscopic circular pits are arranged in a lattice, as shown figure 1 , two adjacent rows of circular pits on the inner and outer rings are staggered at an angle of 45° along the axial direction, and the circular pits on the surface of the ball are staggered at an angle of 45° in the horizontal direction. Lubricating materials are filled into the processed circular pits, the lubrication conditions between the balls and the inner and outer raceways are greatly improved, and the initial roughness between the friction pairs is much lower than that of traditional simple grease lubrication. The wear in the cycle will be reduced a lot, and its life will be greatly improved.

[0037] In this paper, the texture morphology of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com