Valve sealing structure, valve body and low-pressure valve using sealing structure

A valve sealing and valve body technology, used in lift valves, control valves, safety valves, etc., can solve the problem of valve opening pressure exceeding the design pressure, and achieve the effect of improving work stability, improving sensitivity, and facilitating maintenance and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings.

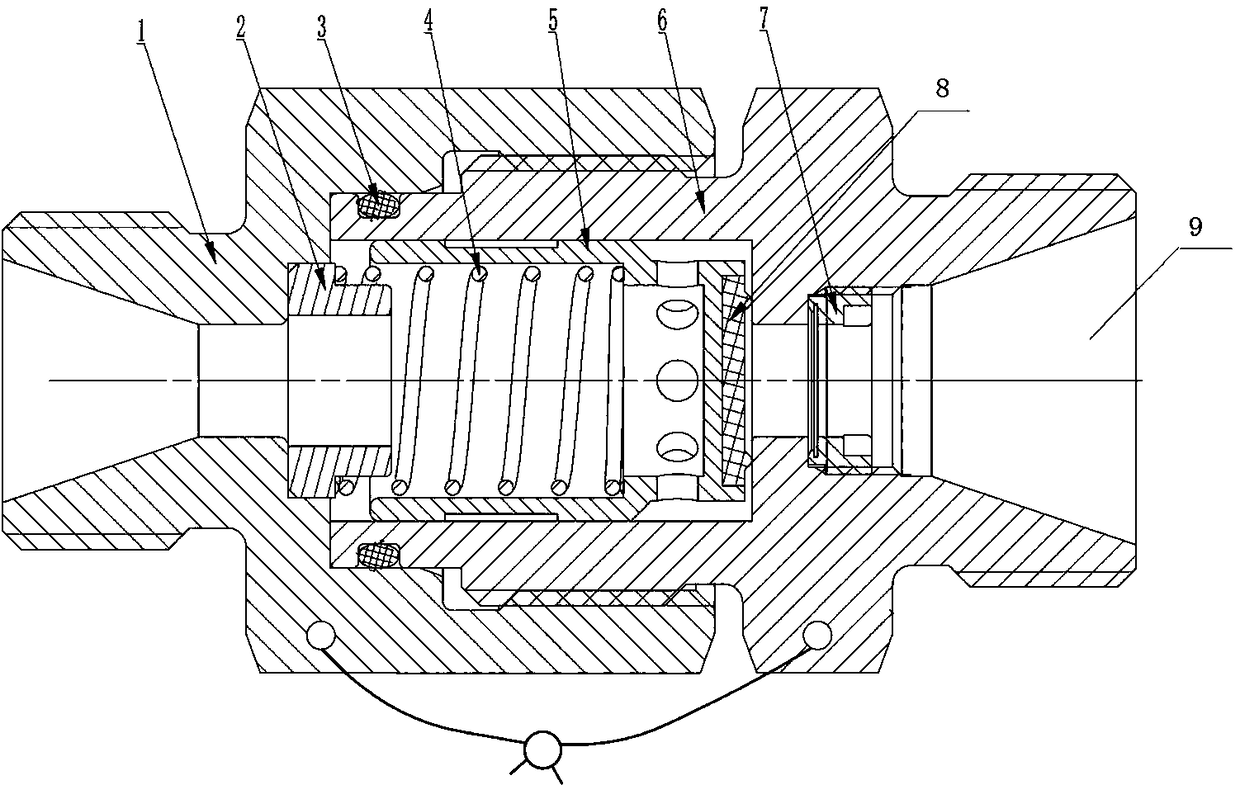

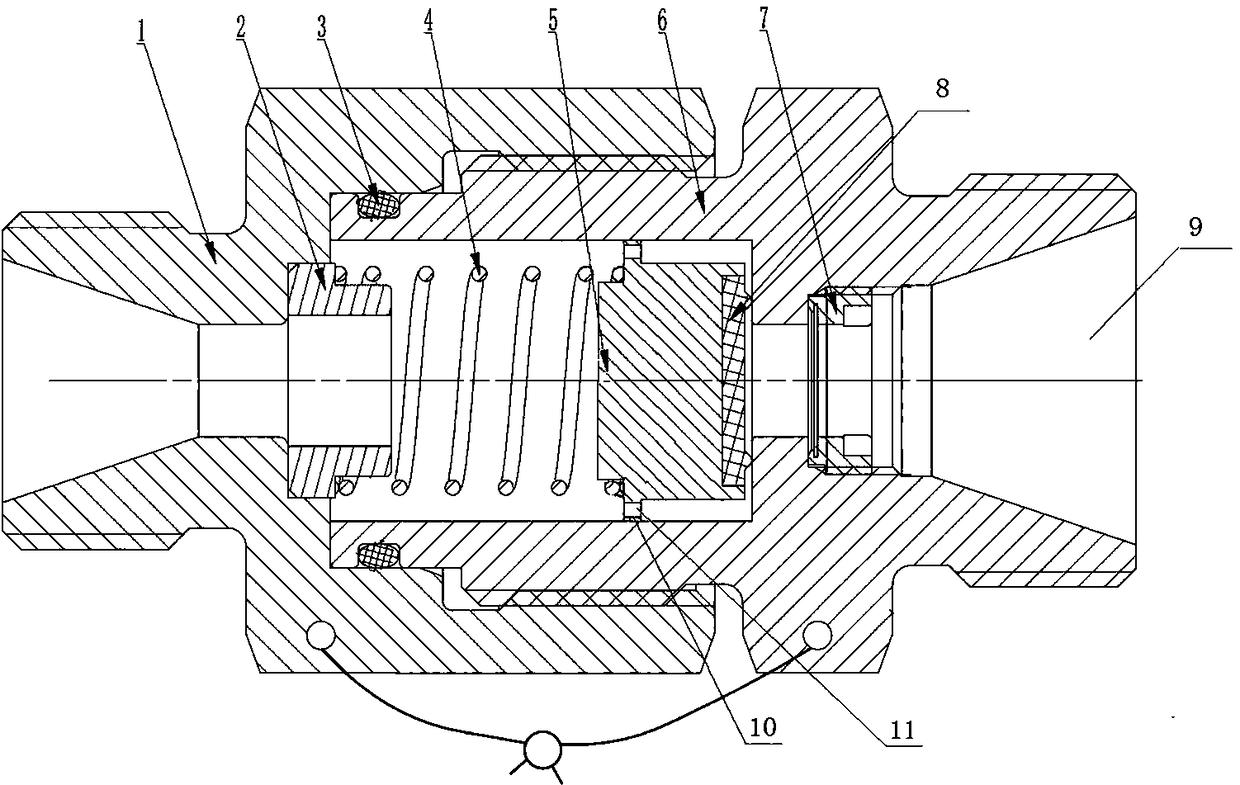

[0027] An embodiment of the valve sealing structure of the present invention figure 1 Shown is a low-pressure one-way valve, which mainly includes a valve body and a valve core 5. The valve body includes a secondary valve body 1, a main valve body 6. One end of the main valve body 6 is provided with a medium inlet 9, and the other end is provided with an external Thread, the auxiliary valve body 1 and the main valve body 6 are connected by a thread and an O-ring 3 is used to achieve sealing. The inner end of the flow passage of the auxiliary valve body is equipped with a spring seat 2 with a circumferential flow hole. The outer peripheral surface of the spring seat 2 is a stepped surface, forming a positioning step for the spring 4 to be sleeved and positioned in the axial direction. The outer circle of the spring seat 2 is The inner hole of the auxiliary valve body 1 has a clearance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com