Round inductosyn capable of eliminating mounting error

A technology of circular induction synchronizer and installation error, applied in the field of circular induction synchronizer, can solve problems such as the increase of angle measurement error, and achieve the effect of eliminating installation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

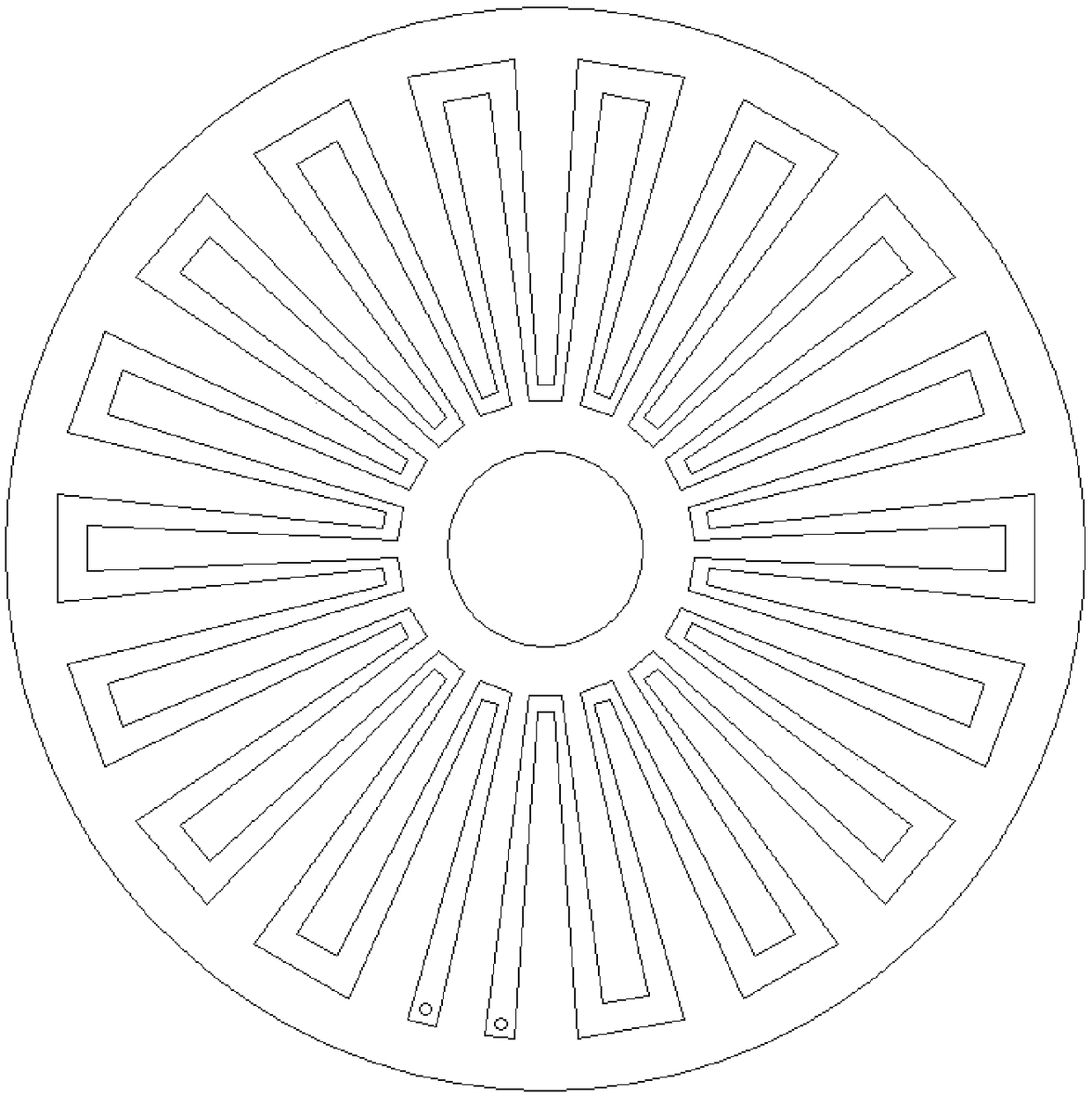

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

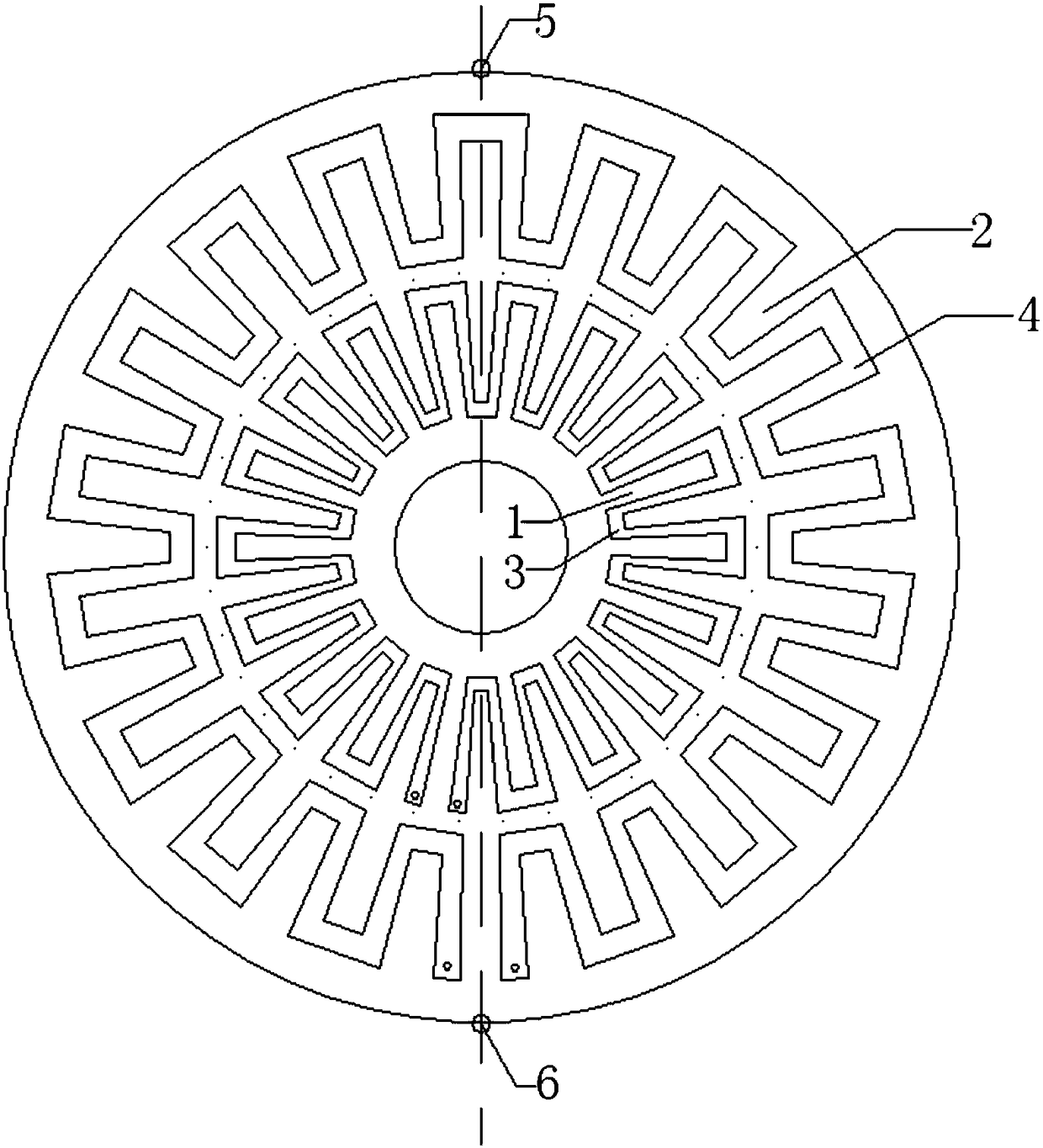

[0014] In this embodiment, the stator winding remains unchanged, and the design of the rotor winding is improved, see the attached figure 2 Shown: In this kind of circular induction synchronizer that can eliminate installation errors, the circular surface of the rotor is divided radially into the inner ring 1 in the middle of the circular area and the outer ring 2 in the outer ring area, The inner ring 1 and the outer ring 2 are concentric, the inner ring winding 3 and the outer ring winding 4 are respectively wound on the inner ring 1 and the outer ring 2, and the inner ring winding 3 and the outer ring winding 4 are staggered by 1 pole pitch along the circumference, that is, the electric Angle π, the width of inner winding 3 and outer winding 4 in the radial direction is equal or the width of inner winding 3 is slightly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com