Drop Hammer Friction Sensitivity Tester for High Energy Insensitive Explosives

A technology of friction sensitivity and falling weight, which is applied in the direction of instruments, measuring devices, and mechanical devices, etc., can solve the problems of the impact energy of the friction plate, the impact of the test repeatability, and the increase of the matching gap, so as to reduce the impact damage and friction. Stable state and reduced frictional loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

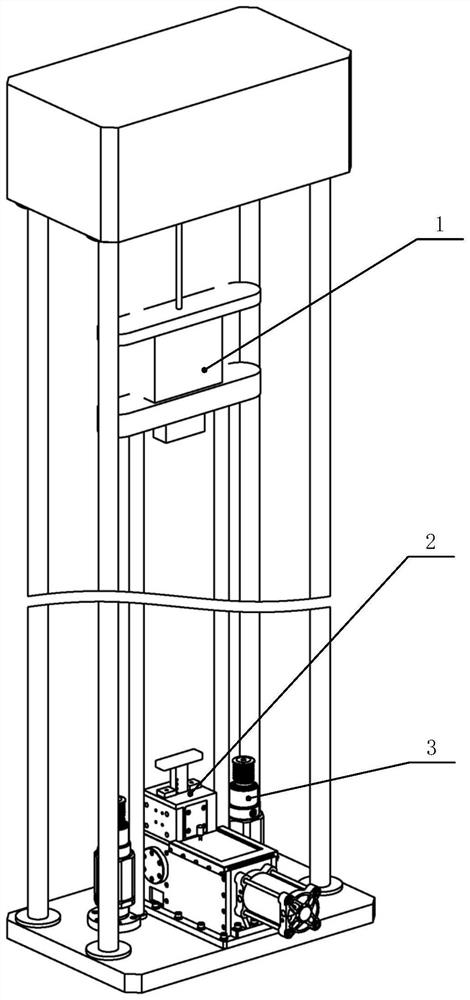

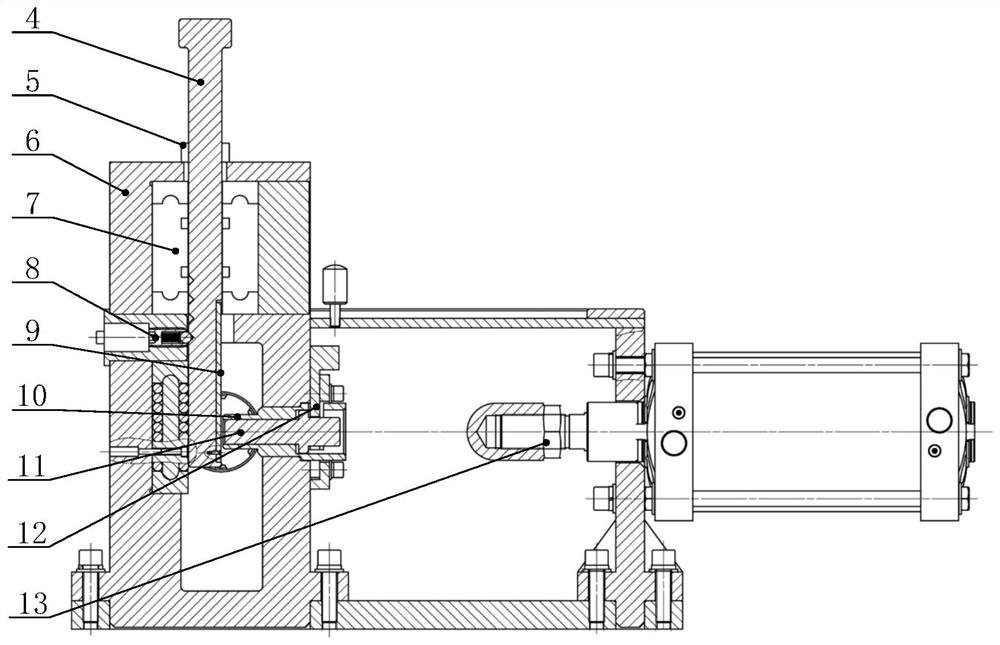

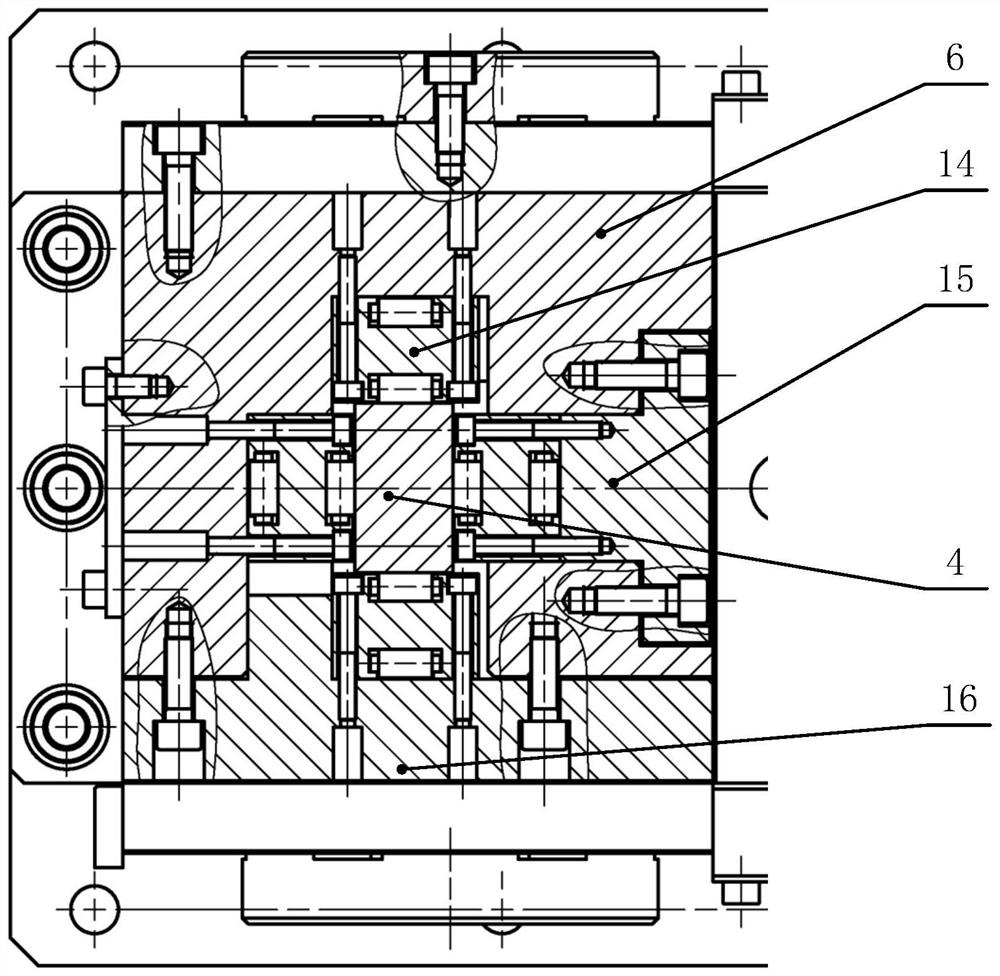

[0026] The overall structure of the falling hammer type high-energy insensitive explosive friction sensitivity tester is as follows: figure 1 , which is mainly composed of three parts: automatic drop hammer assembly 1, friction factor loading assembly 2 and drop hammer buffer assembly 3. The fully automatic drop hammer assembly 1 mainly consists of two parts: the lifting hammer and the release device that can set the height of the lifting hammer at will, and the dropping hammer that can adjust the quality by adding or subtracting weights. The friction factor loading assembly is installed directly under the drop hammer, and its main components are as follows: figure 2 As shown, it includes a slide plate 4, a slide plate buffer pad 5, a base 6, a slide plate guide unit 7, a slide plate height positioning device 8, a friction target plate 9, a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com