Pressure-reducing valve closed ring control system with variable output pressure

A technology of output pressure and closed-loop control, applied in electric controllers, controllers with specific characteristics, etc., can solve the problems of increased maintenance costs, waste of energy, resources, etc., to reduce the probability of water leakage and pipe burst, save energy, maintain The effect of normal service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

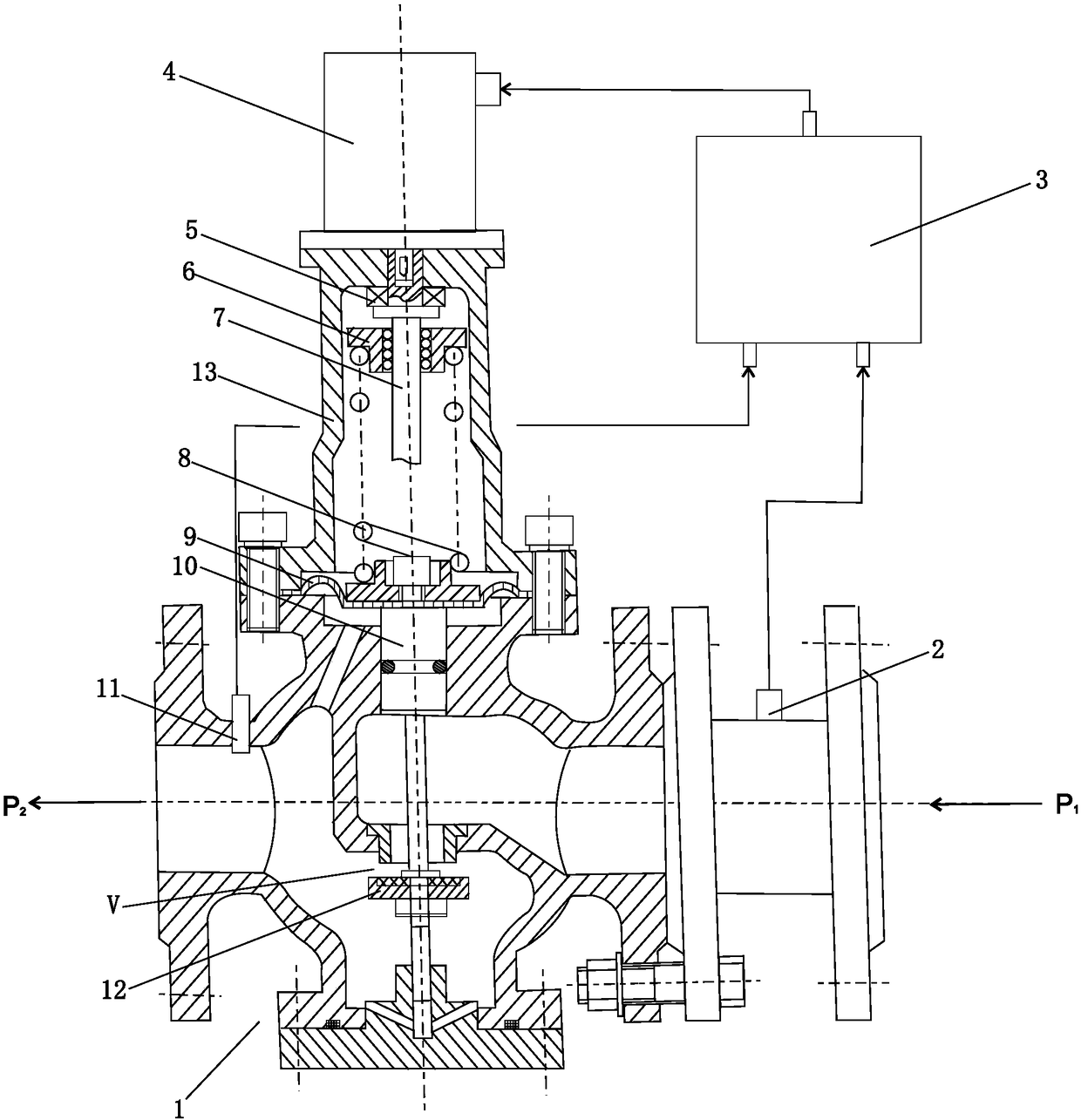

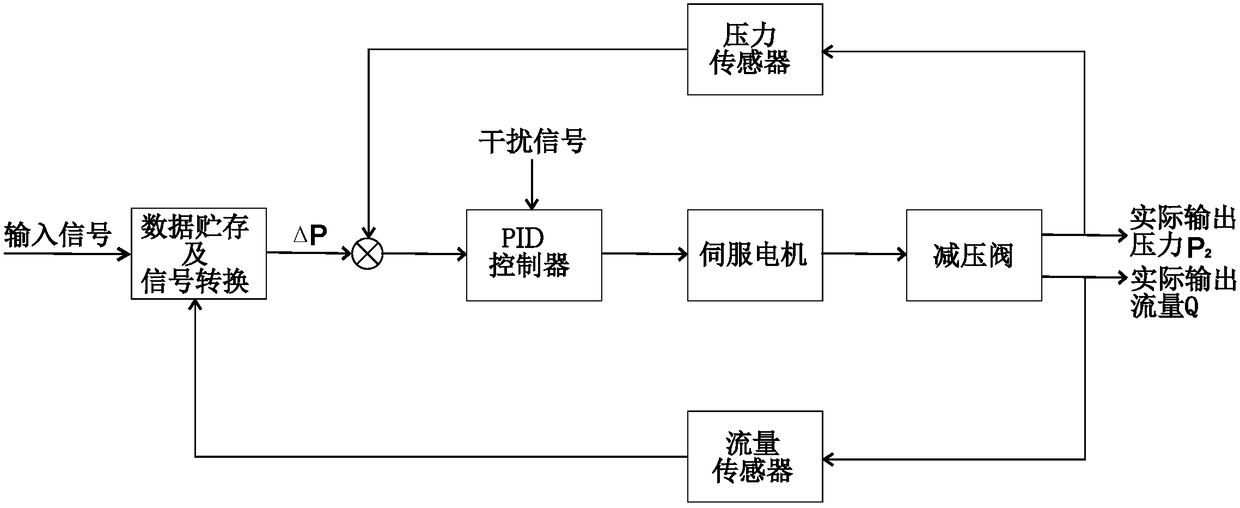

[0027] Such as figure 1 As shown, a closed-loop control system for a variable output pressure pressure reducing valve includes a pressure reducing valve with a pressure regulating mechanism 1, a flow sensor connected in series to the inlet end A of the pressure reducing valve 1, and an outlet of the pressure reducing valve 1 The pressure sensor 11 at the end B, the servo motor 4 installed at the top of the pressure reducing valve 1, and the control box 3. The control box 3 is equipped with a data storage and signal conversion module, a comparison module, and a PID controller. The input interface of the flow sensor 2 is connected with the actual flow input interface of the pressure reducing valve 1, the output interface of the flow sensor 2 is connected with the input interface of the above-mentioned data storage and signal conversion module, and the output interface of the data storage and signal conversion module is connected with the comparison module. Input interface connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com