Disc type motor rotor with embedded magnetic poles

A disc motor and magnetic pole technology, which is applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, and magnetic circuit shape/style/structure, etc. , to achieve the effect of easy field weakening control, low magnetic field loss and large inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

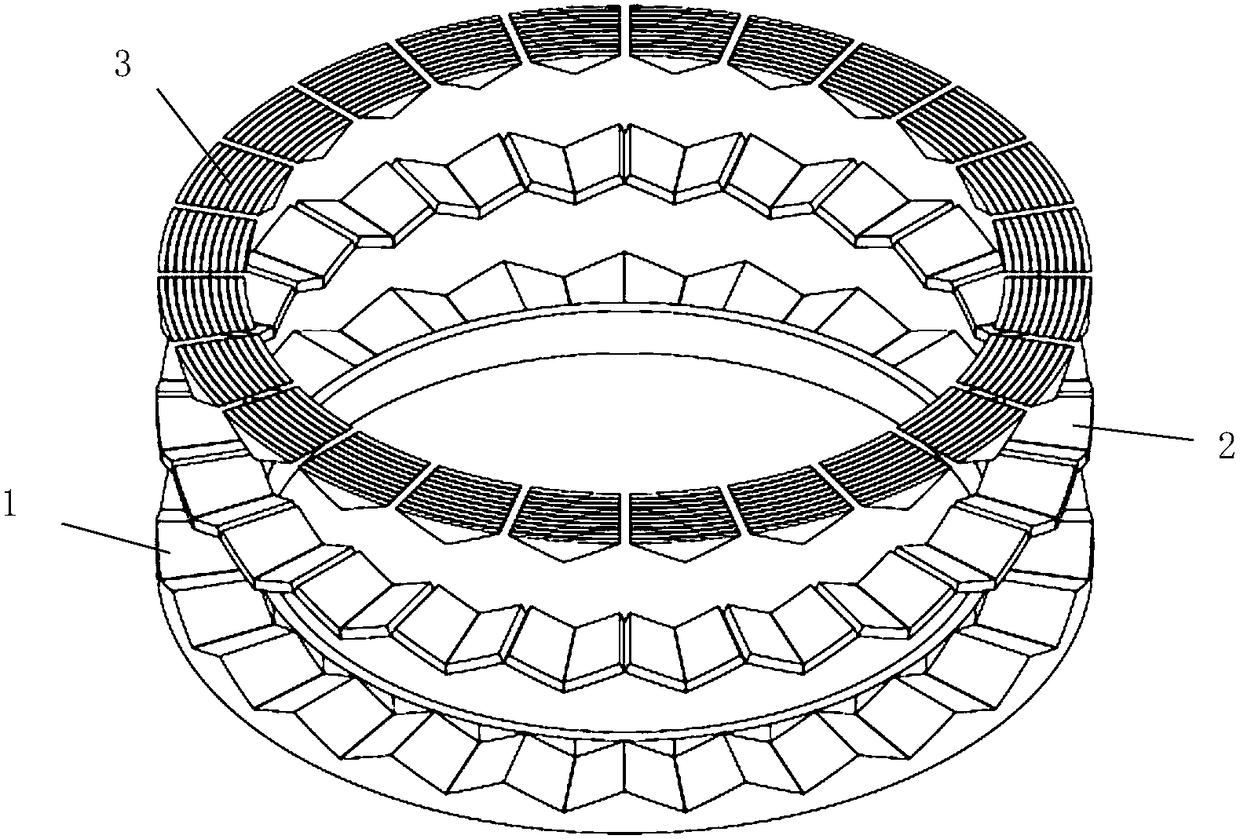

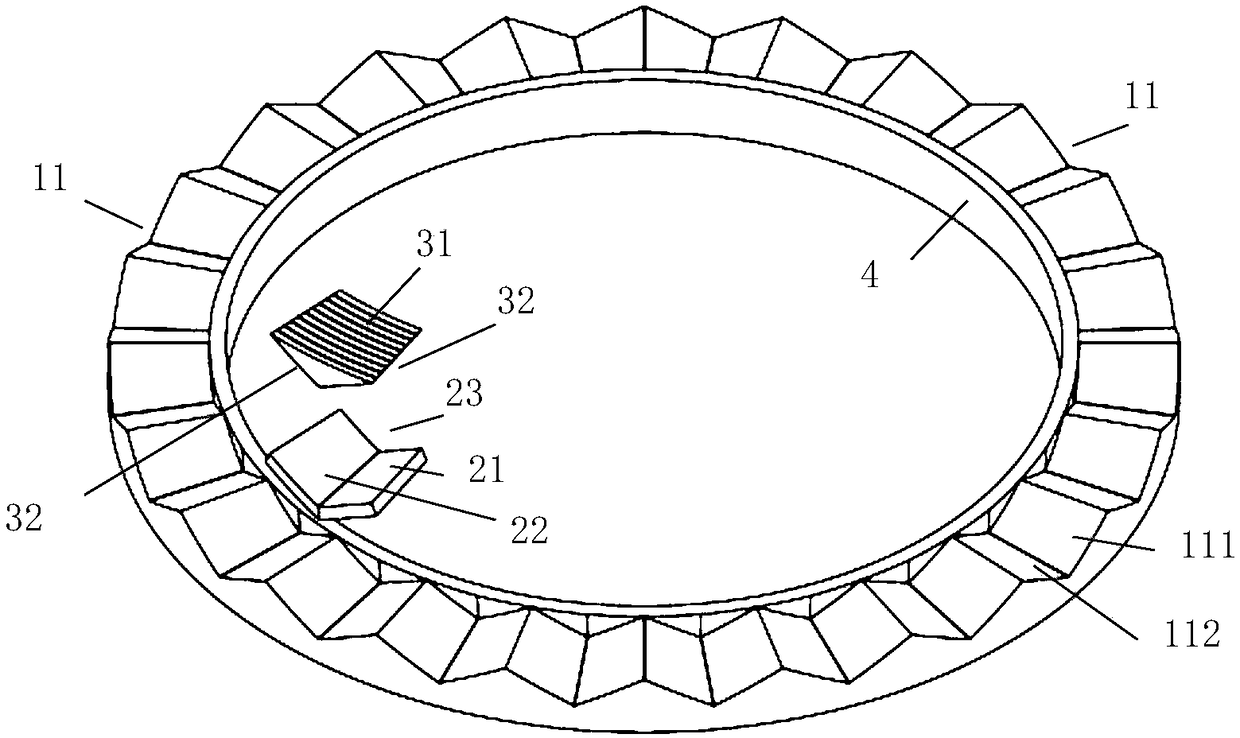

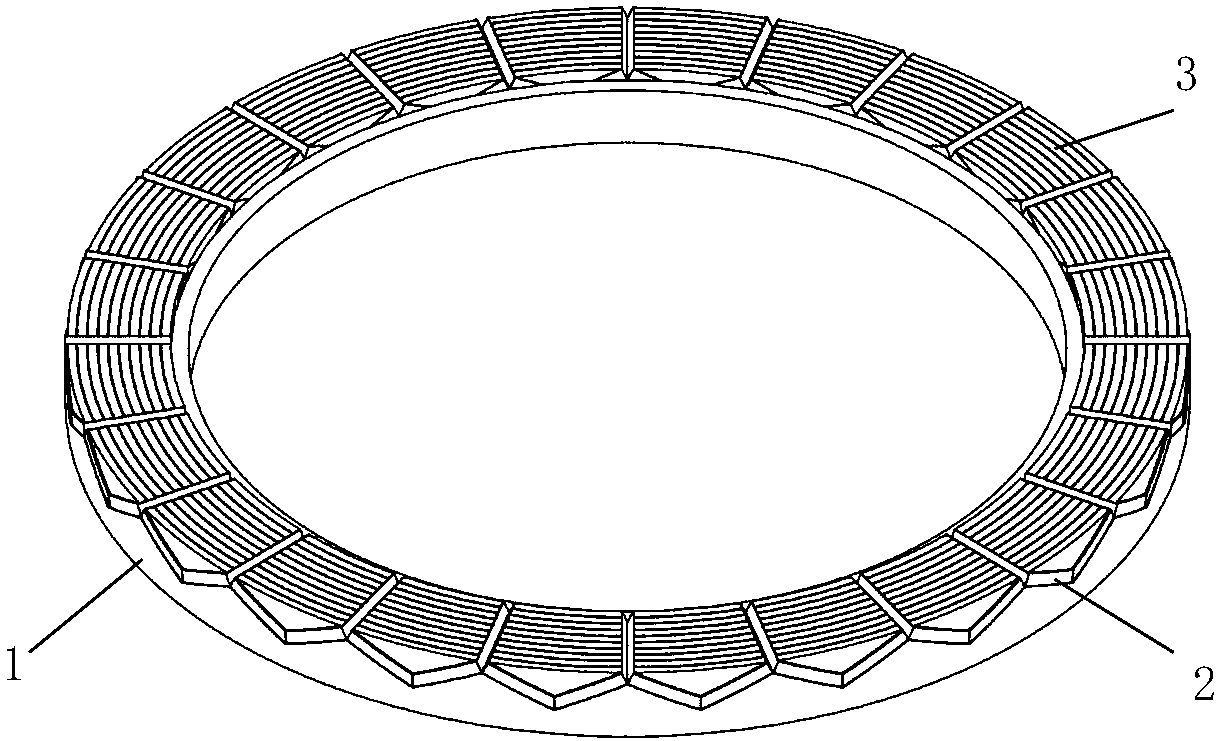

[0028] like Figure 1-3 As shown, the disc motor rotor with embedded magnetic poles of the present invention includes a rotor back plate 1 , magnetic poles 2 , surface iron core 3 and inner ring limit ring 4 .

[0029] The rotor back plate 1 is in the shape of a ring and integrally formed. It can be processed from a whole piece of material, or it can be formed from silicon steel coiled into a roll and then cut. The upper surface of the rotor back plate 1 is continuously formed with a plurality of magnetic pole slots 11 for fitting the magnetic poles 2, each magnetic pole slot 11 is a slot surrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com