Wind-conveying type defoliation and collection integrated machine for stevia rebaudiana

A stevia and all-in-one machine technology, which is applied in application, food processing, food science, etc., can solve the problems of wasting manpower, high leaf crushing rate, and slow defoliation speed, so as to reduce the leaf crushing rate, reduce impurities, and reduce impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

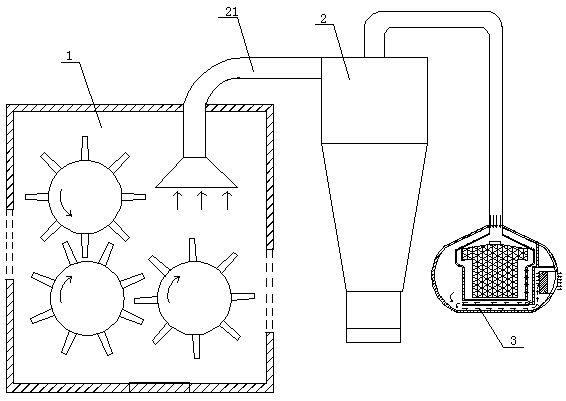

[0040] See figure 1 , A wind-driven stevia defoliation and collection integrated machine, comprising a defoliation warehouse 1, a collection warehouse 2, an air suction device 3, and an air duct 21. The defoliation warehouse 1 is used to defoliate the stems and leaves of the stevia Separation, the collection bin 2 is used to separate the blades from the air flow and collect the blades, the air duct 21 is connected to the defoliation bin 1 and the collection bin 2, and the suction device 3 is used to generate negative pressure to provide the air duct 21 and the collection bin 2 The air flow between the air guide tube 21 sucks the blades from the defoliation chamber 1 into the collection chamber 2.

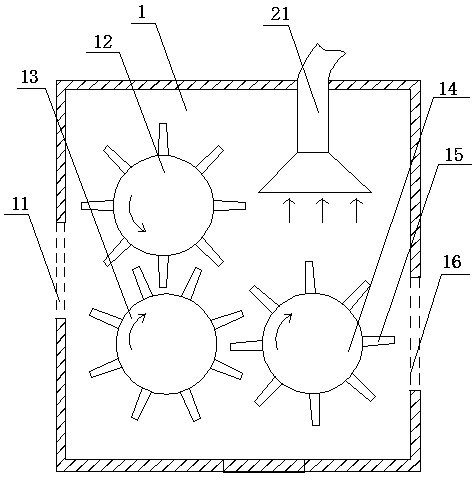

[0041] See figure 2 , The specific structure of the defoliation bin 1 is as follows: the bin body is provided with a feed inlet 11 and a stem rod outlet 16, a first roller 12 and a second roller 13 are arranged up and down near the feed inlet 11 in the bin body, and the bin body is clo...

Embodiment 2

[0046] See figure 2 On the basis of Embodiment 1, the difference of this embodiment is that the specific operation modes of the first roller 12, the second roller 13 and the third roller 14 are:

[0047] The distance between the closest points of the first roller 12 and the second roller 13 is greater than the length of one elastic rod 15 and less than the length of the two elastic rods 15. The elastic rods 15 on the first roller 12 and the second roller 13 are mutually Staggered, the first roller 12 and the second roller 13 rotate in opposite directions;

[0048] The distance between the closest points of the second roller 13 and the third roller 14 is greater than the length of one elastic rod 15 and less than the length of the two elastic rods 15. The elastic rods 15 on the second roller 13 and the third roller 14 are mutually Staggered, the second roller 13 and the third roller 14 rotate in the same direction.

[0049] In this embodiment, the first roller 12 and the second rolle...

Embodiment 3

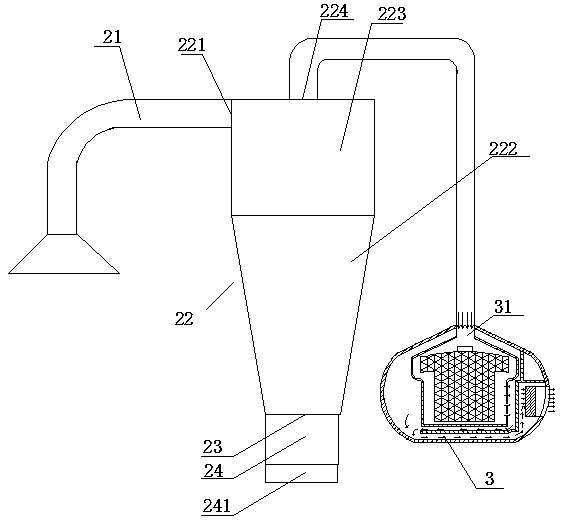

[0051] See image 3 On the basis of embodiment 1, the difference of this embodiment is that the collection bin 2 includes a cyclone separator 22 and a collecting hopper 24 that are connected to each other, and the cyclone separator 22 includes a cylindrical portion 223 and a cone portion 222. The part 223 is provided with a tangent inlet, the air inlet 221 is provided at the tangent inlet, the air outlet 224 is provided at the top of the cylindrical part 223, and the bottom of the cone part 222 is provided with a blade outlet 23, which is connected to the collecting hopper 24.

[0052] The cyclone separator 22 is used to separate the blades from the air flow. The separated blades reach the blade outlet 23 and fall into the collecting hopper 24. The separated air flow passes from the air outlet 224 to the suction port 31 of the suction device 3, and finally from the exhaust port 33 is discharged.

[0053] Furthermore, a pressure gate 241 is provided at the bottom of the collecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com