GMT material and LWRT material composite forming mold

A combined molding and mold technology, applied in the field of auto parts processing, can solve troubles and other problems, and achieve the effect of avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following embodiments may enable those skilled in the art to fully understand the present invention, but they do not limit the present invention to the scope of the described embodiments.

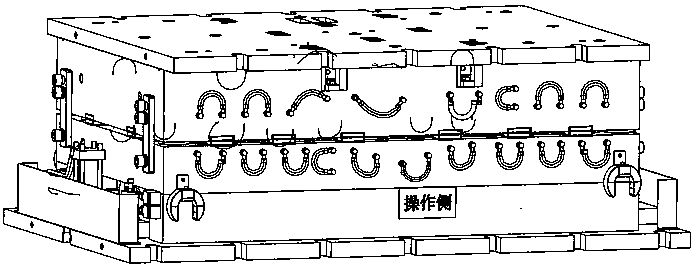

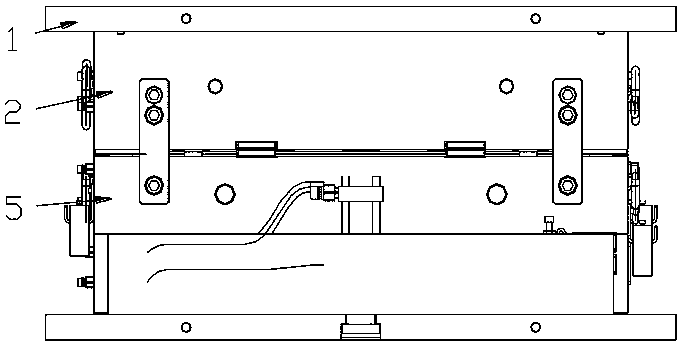

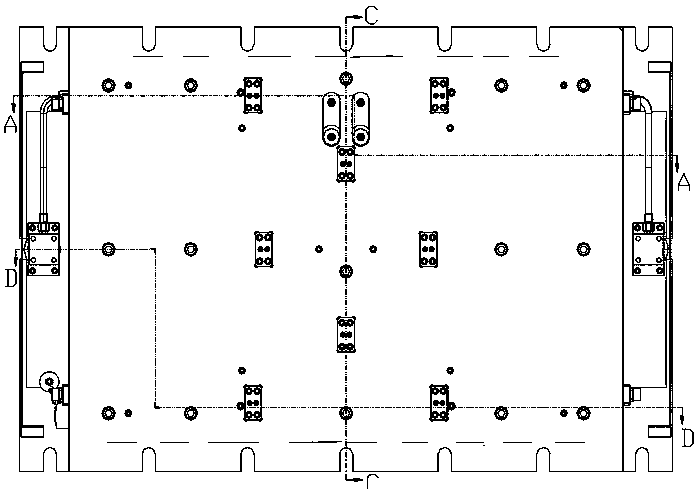

[0038] Such as Figure 1-Figure 11 A GMT material and LWRT material combined molding die shown includes

[0039] A pair of upper top plate 1 and bottom plate 10 distributed up and down. The upper mold core 2 and the lower mold core 5 are respectively installed on the lower end of the upper top plate 1 and the upper end of the bottom plate 10, and the upper mold core 2 and the lower mold core 5 are shared after being closed. A mold cavity formed of GMT material and LWRT material is formed. A pair of anti-wrinkle floating pre-compression molding structures for pre-compression molding of LWRT materials are installed on the upper mold core 2. A number of ejector pins 47 are also distributed on the lower mold core 5. A number of hard limits 29 are also arranged around the mold core 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com