LED ceiling lamp with optical lens cover

A technology of LED ceiling lamp and optical lens, which is applied in the field of LED lighting, can solve the problems of increasing labor cost, increasing assembly difficulty, increasing material cost, etc., and achieves the effect of improving heat dissipation effect, not increasing cost, and reducing processing and assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

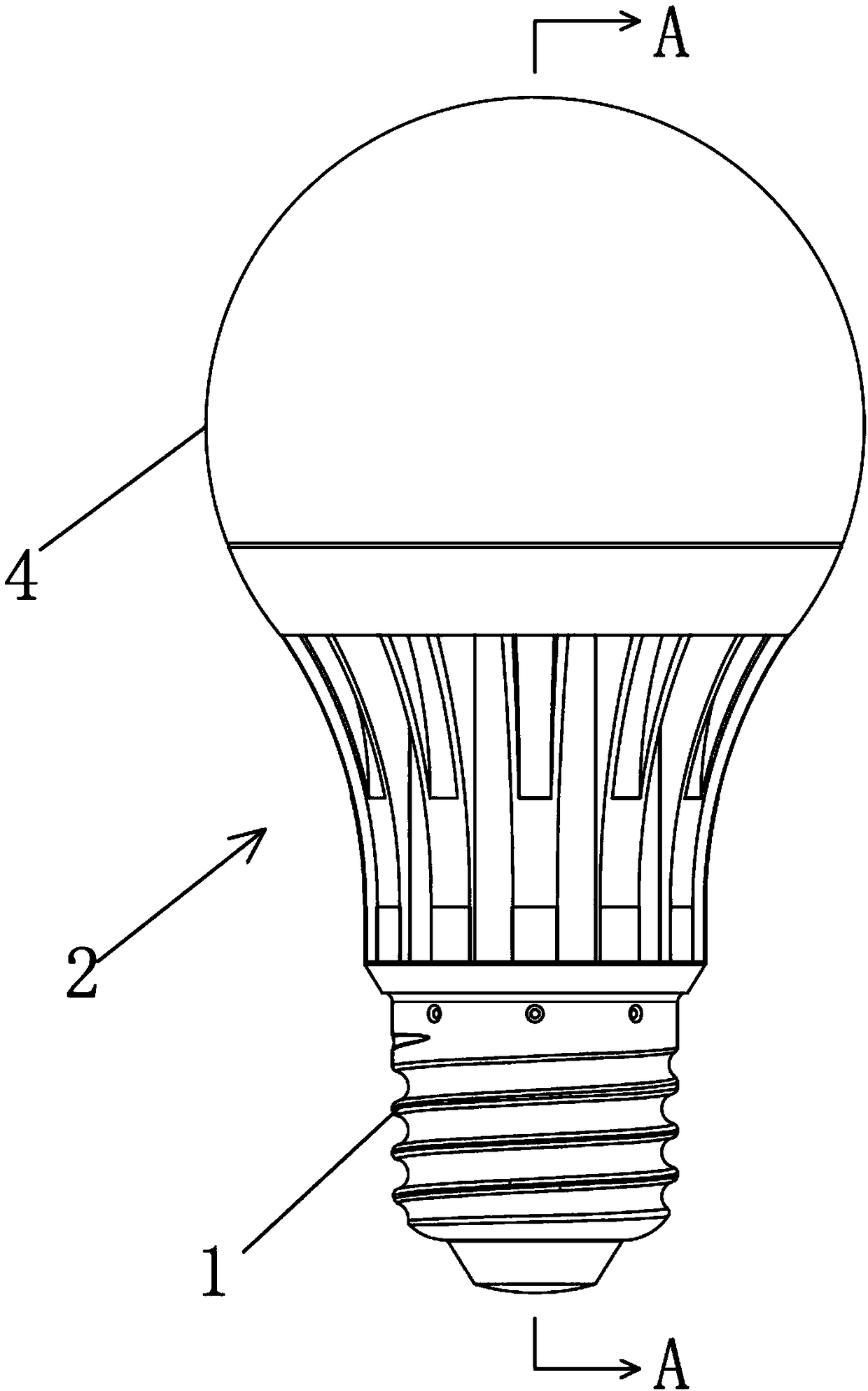

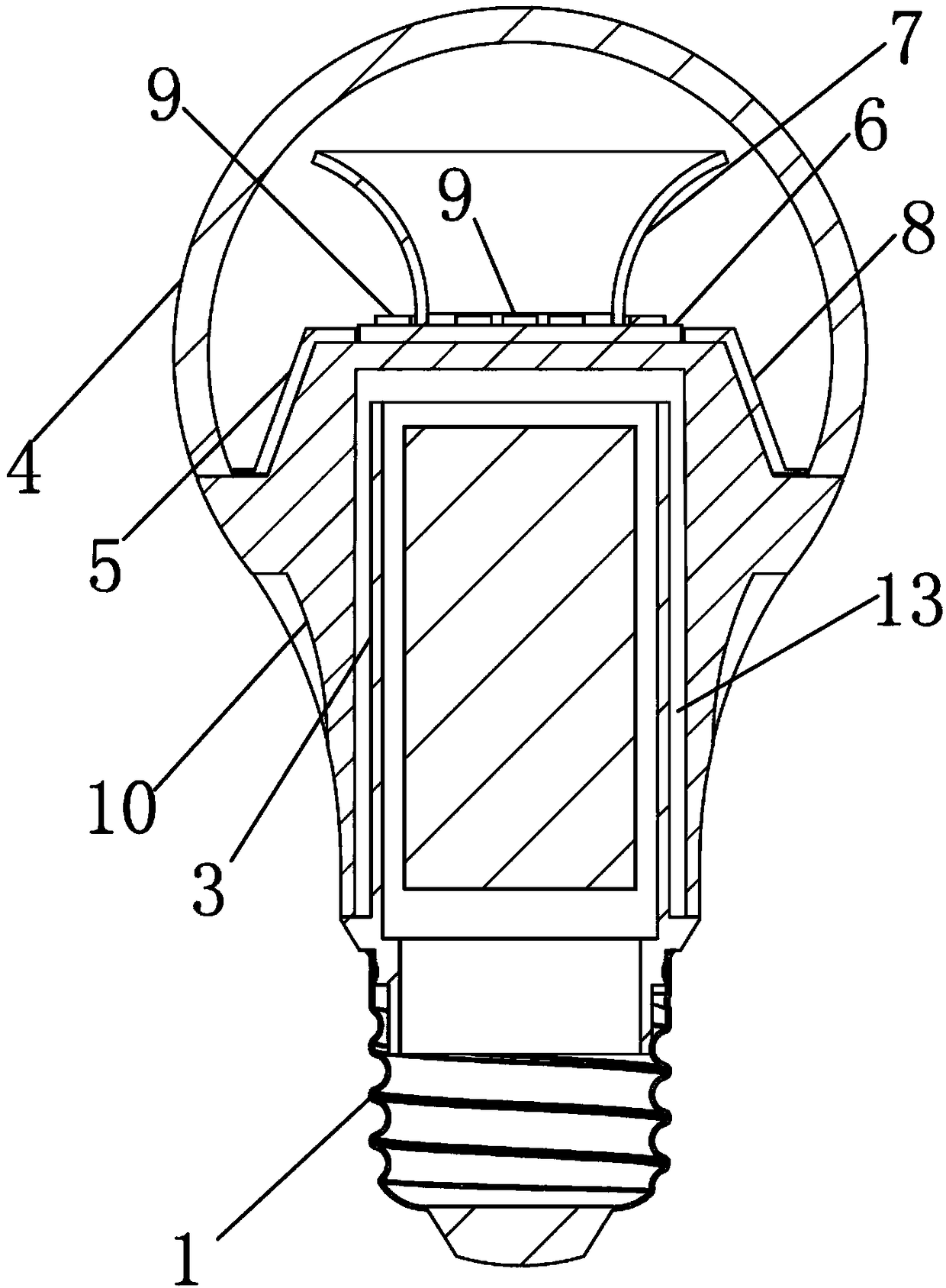

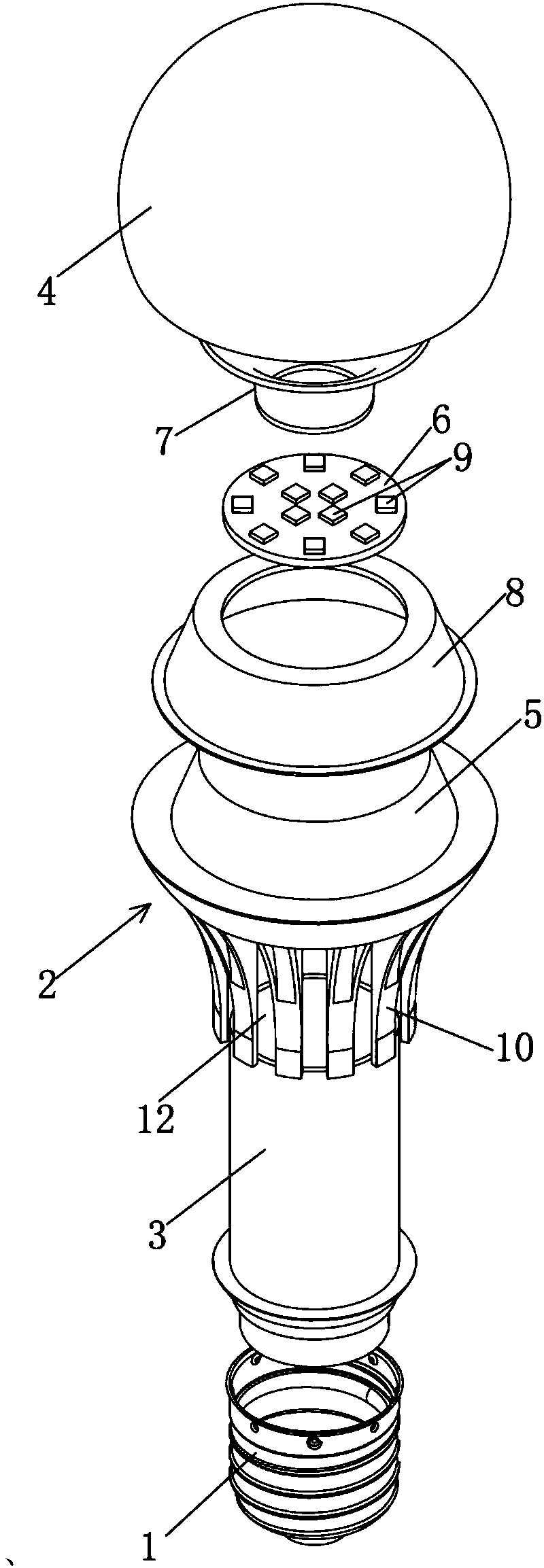

[0040] Embodiment 1: as figure 1 As shown in ~7, an LED ceiling lamp with an optical lens cover includes a lamp base 1, a lamp body 2, a power supply housing 3 and a bulb 4, and the lamp body 2 is made of an aluminum heat sink or is made of heat-conducting plastic , ceramics and other materials, the interior of the lamp body 2 is a hollow structure, the lamp body 2 and the power supply housing 3 are socketed together, and the power supply housing 3 is made of heat-conducting plastic, which can effectively dissipate heat; A lamp holder 5 protruding from the upper surface of the lamp body 2 is provided on the upper part of the lamp body 2. The longitudinal section of the bulb shell 4 is an arc larger than a semicircle, and the opening of the bulb shell 4 is installed on the periphery of the upper surface of the lamp body 2. . The shape of the outer contour of the lamp holder 5 can be any shape in polyhedron, cylinder or frustum of a cone. In this embodiment, the shape of the o...

Embodiment 2

[0045] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a plurality of cup petals 14 are uniformly arranged on the upper end of the reflective cup 7 along the circumferential direction, and gaps 15 are formed between two adjacent cup petals 14 . The purpose of setting the gap is because if there is a bulb or lampshade outside the reflector cup of the LED light, on some specific bulbs or lampshades, although there is no problem with the light distribution curve of the lamp, there may be a circle of dark areas on the bulb or lampshade , set the gap 15, so that part of the light of the external LED light source 9 of the reflector 7 can pass through, and solve the dark area that may be generated on the bulb or lampshade.

Embodiment 3

[0046] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the cup petals 14 are more slender, and the corresponding notch 15 is also more slender.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com