Method for winding high-precise resistor

A winding method and high-precision technology, which is applied in the direction of winding resistance elements, etc., can solve the problems that general resistance cannot be used, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

[0023] A winding method of a high-precision resistor of the present invention comprises the following steps:

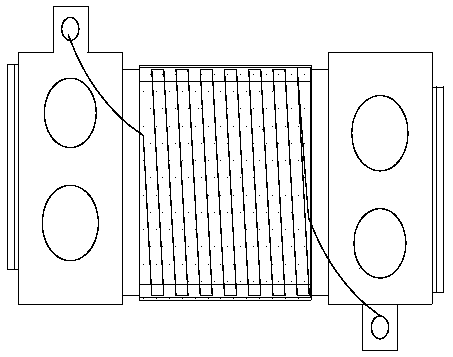

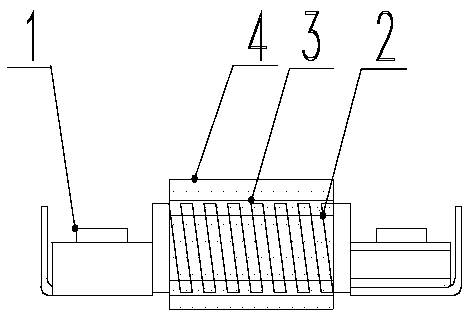

[0024] 1) Enamelled manganin wire (2) is wound around the middle part of the skeleton (1); both ends of the skeleton (1) are metal welding posts, and the middle part is non-metallic. Such as figure 2 shown.

[0025] 2) Weld the initial end of the enamelled manganese-copper wire (2) on the through hole of the welding post of the skeleton (1), and temporarily fix the other end with high-temperature adhesive tape; figure 1 shown.

[0026] 3) Bake the assembly formed in step 2) in an oven at 180°C for 24 hours to eliminate the winding stress;

[0027] 4) After the components baked in step 3) are naturally cooled, measure the resistance at both ends of the enamelled manganese-copper wire (2), if th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com