A mold mirror surface processing technology and processing equipment thereof

A technology of mirror surface processing and mould, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as easy sticking, difficult removal, and drifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

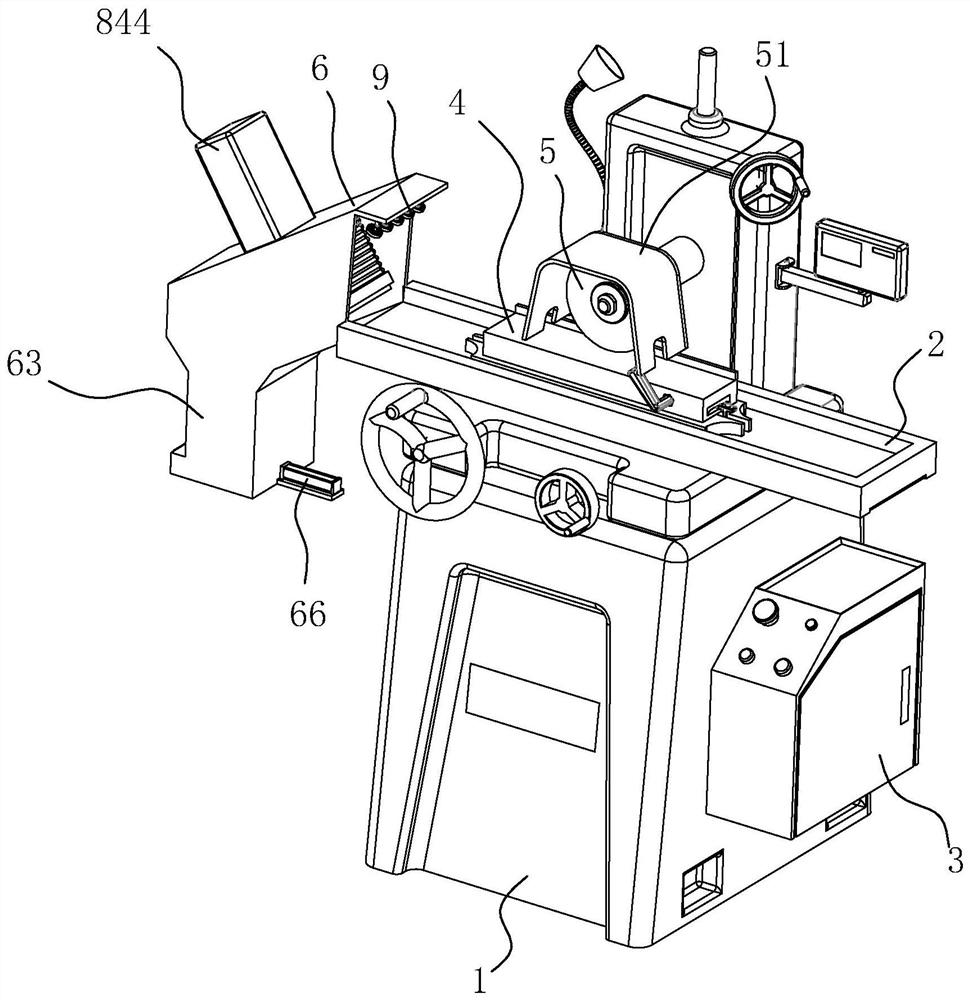

[0045] refer to figure 1 , is a mold mirror processing equipment disclosed in the present invention, comprising a base 1, a workbench 2 is installed on the base 1, a console 3 is arranged on the side of the workbench 2, and a mold clamping seat for fixing the mold is fixed in the center of the workbench 2 4. A grinding wheel 5 for grinding the mold is arranged above the mold clamping seat 4, and a shielding plate 51 covering the sides and top of the grinding wheel 5 is also provided. When grinding the mould, along with the rotation of the grinding wheel 5 , debris generated by grinding will splash towards one side of the workbench 2 .

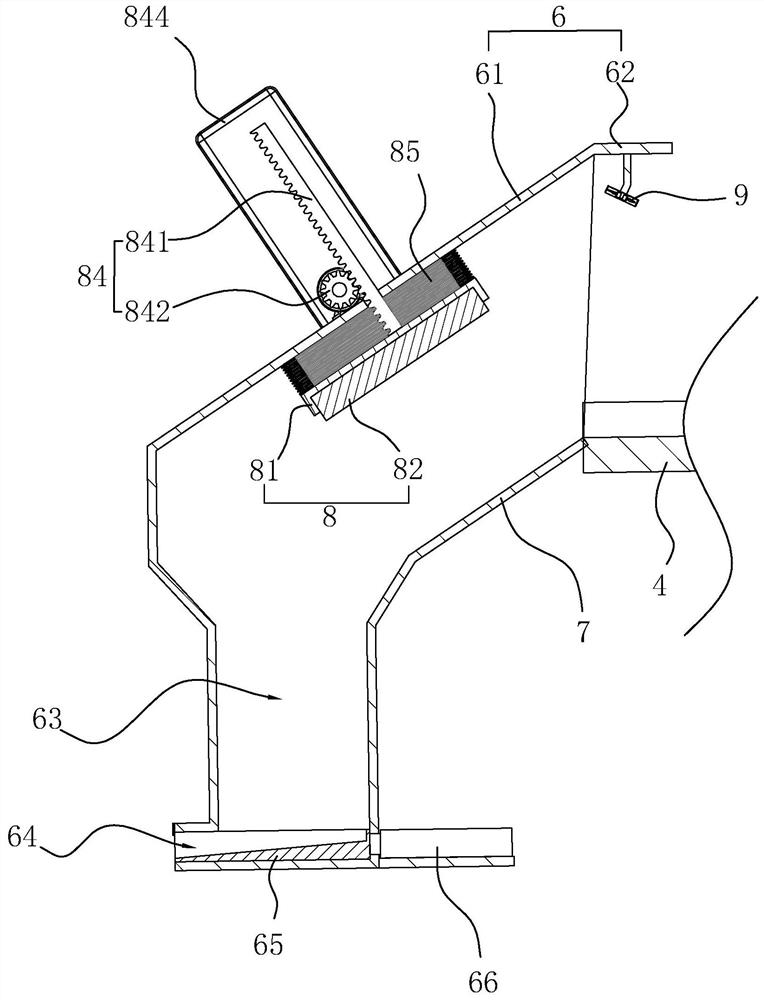

[0046] Such as figure 1 with figure 2 As shown, one side of the workbench 2 is provided with a debris collection device, including a collection cover 6 fixed on the workbench 2. The lower surface of the collection cover 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com