Double-station pump vacuum processor with uniform vacuumizing function

A vacuum treatment and processor technology, applied in the field of vacuuming, can solve the problems of increased vacuum pump load, uneven etching, hindering the application of double-station vacuum processors, etc., and achieve the effect of effective electrical isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

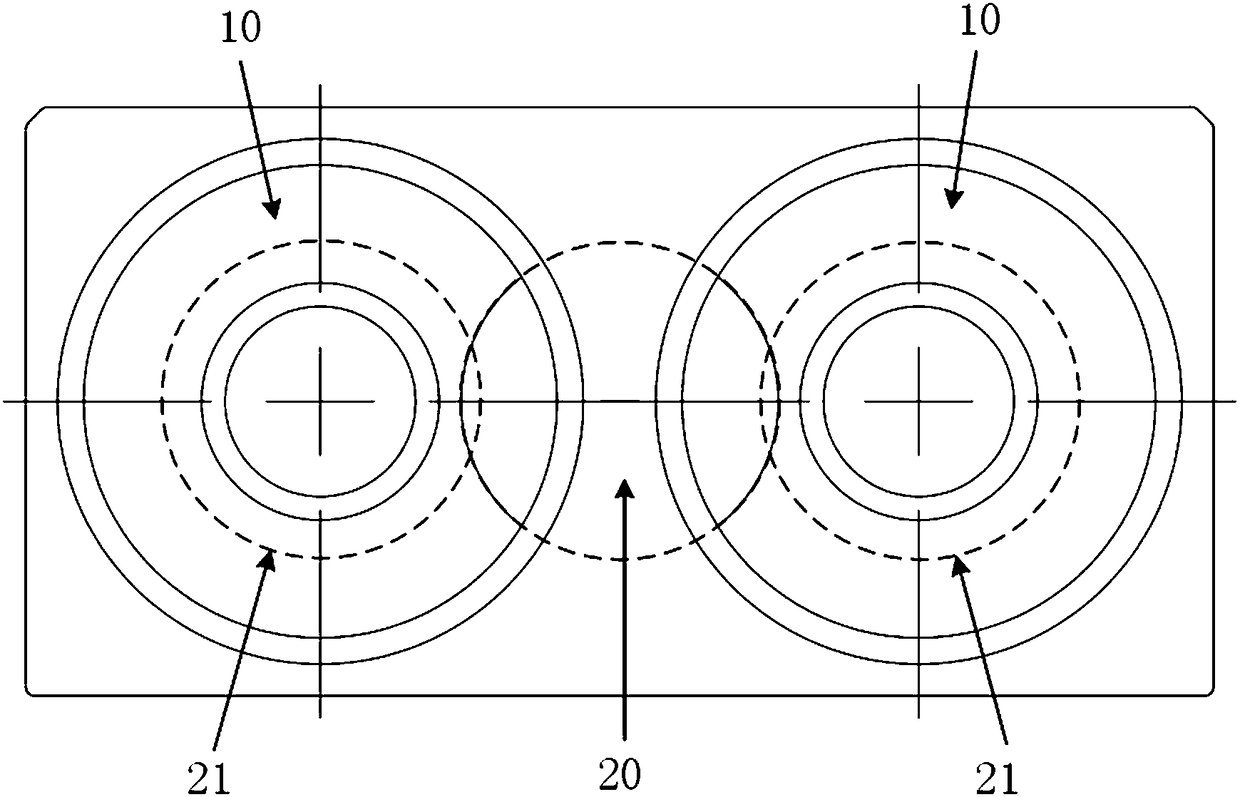

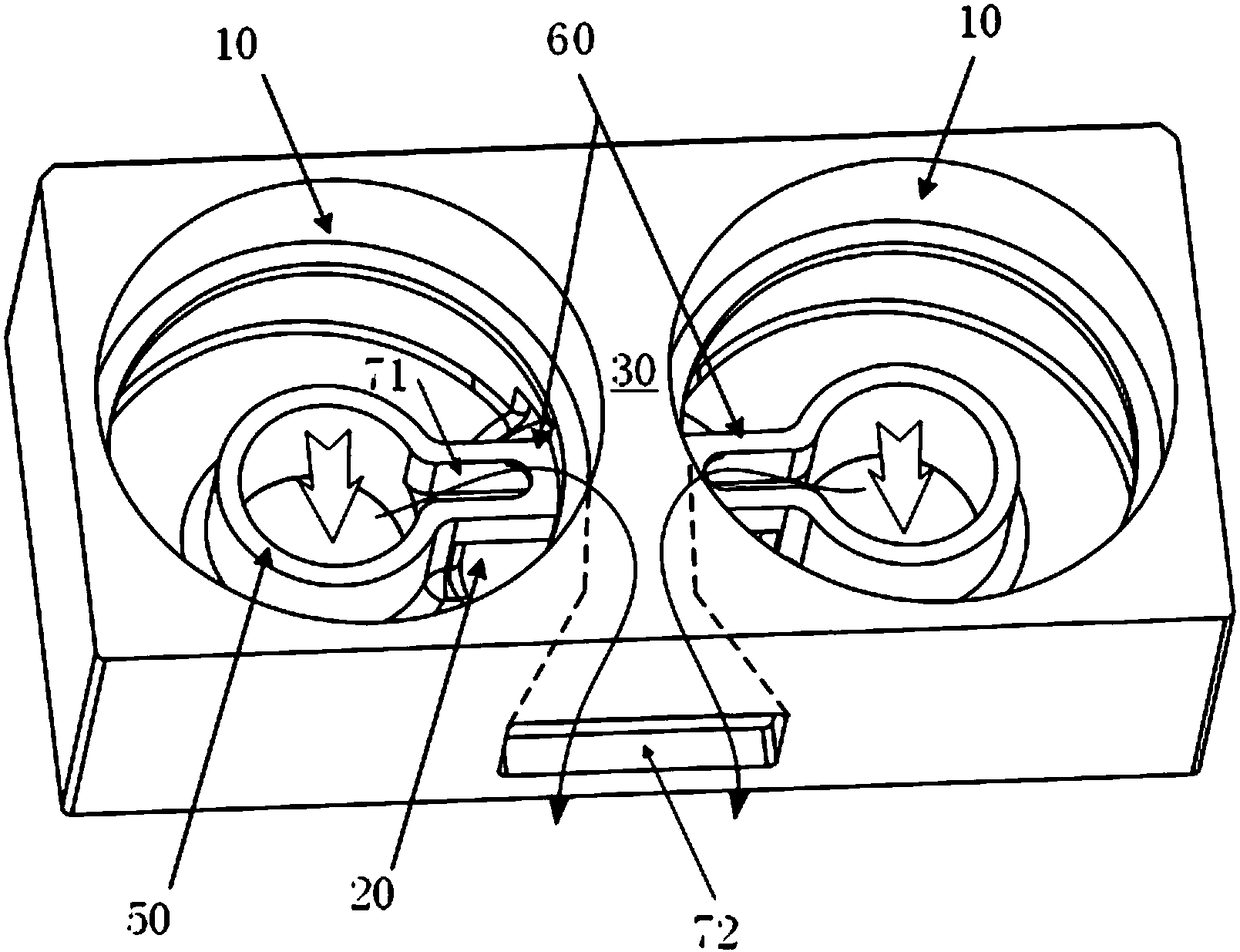

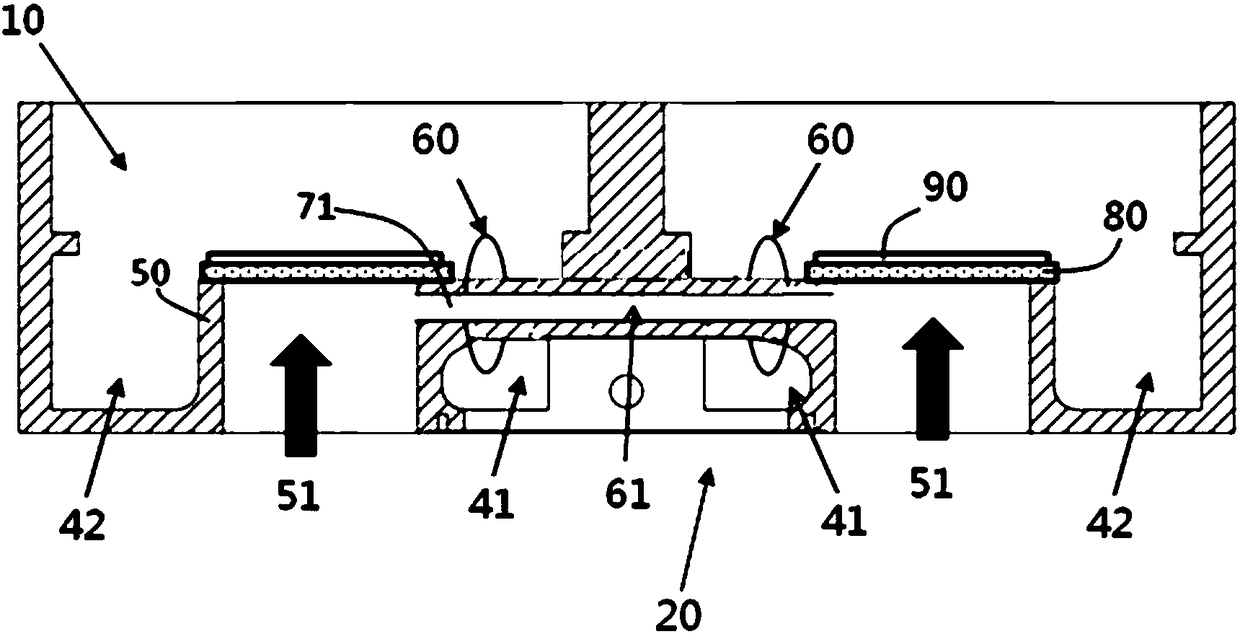

[0026] Hereinafter, the present invention will be described by taking an eccentrically evacuated double-station vacuum processor used in a plasma processing device (such as an etching device) with two vacuum processing chambers sharing a set of vacuum generating circuits as an example.

[0027] The design of the double-station vacuum processor needs to solve two problems:

[0028] 1) Try to ensure the smoothness of the pumping channel, increase the flow conductance to maximize the performance of the vacuum pump, so that the chamber can obtain a relatively ideal vacuum degree, and ensure the maximum adjustability of the process pressure.

[0029] 2) Design a compensation mechanism to ensure the uniformity of pressure and flow velocity from 0 to 360 degrees in the single-station cavity: pressure uniformity: < 1%; flow velocity uniformity: < 20%.

[0030] The two vacuum processing chambers of the double-station vacuum processor are adjacently arranged in the same housing structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com