Environment-friendly grain vibration cleaning screen

An environment-friendly, vibrating screen technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of harsh working environment, prolonging the shelf life of food and grain, and damaging the health of staff, and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

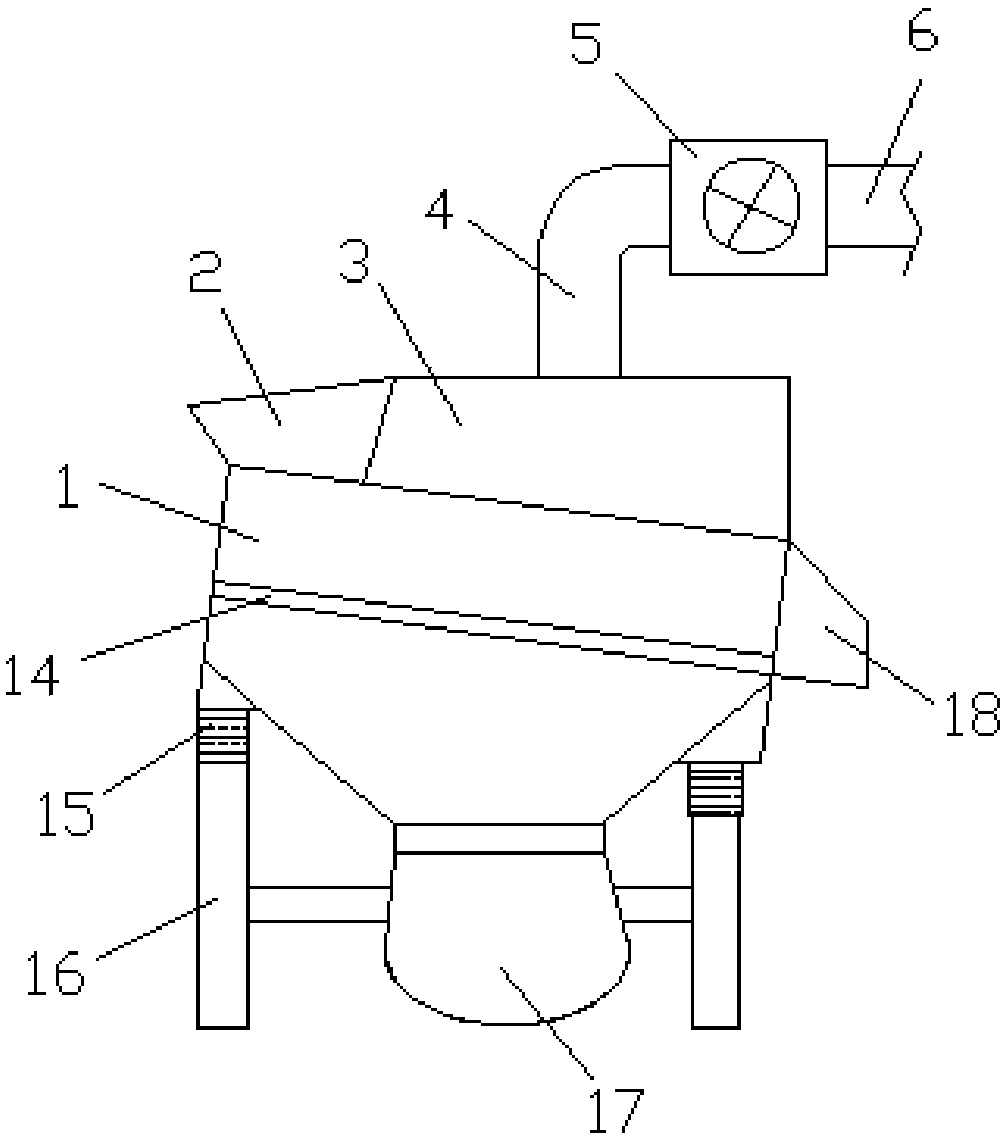

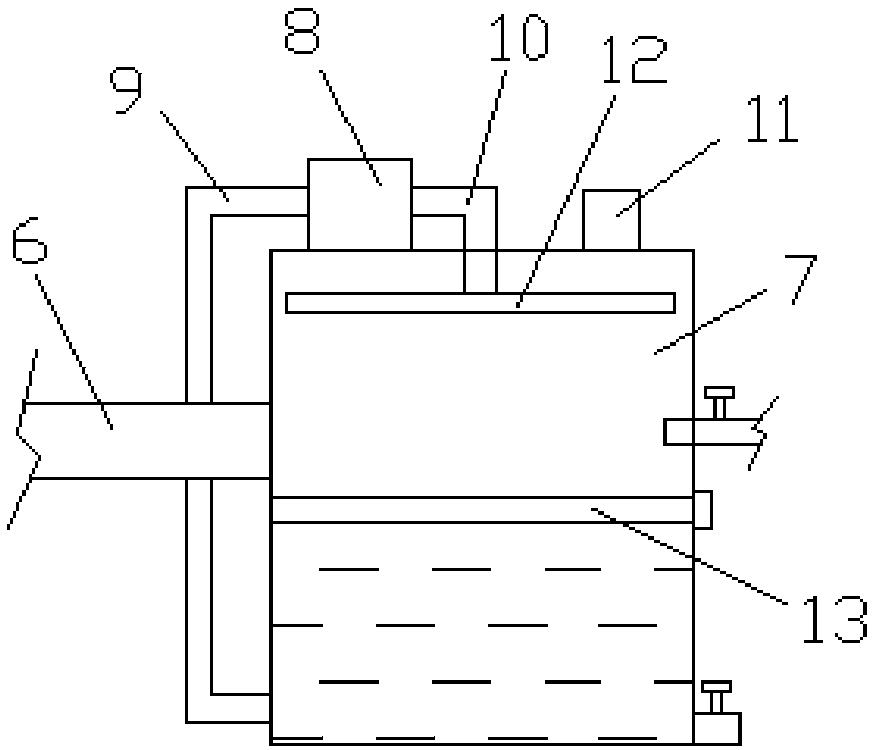

[0017] Such as Figure 1-2 As shown, an environment-friendly grain vibrating cleaning sieve comprises a vibrating sieve 1, the top of the vibrating sieve 1 is provided with a feeding port 2, and one side of the feeding port 2 is provided with a dust suction cover 3, and the top of the dust suction cover 3 is A dust suction pipe 4 is provided, and a fan 5 is provided at one end of the dust suction pipe 4, and the dust generated in the process of screening out grain impurities can be sucked away and discharged through the dust suction cover 3 and the dust suction pipe 4, so as to avoid being mixed into the grain and affecting food quality, or diffuse in the air to pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com