Clamp suitable for continuous processing of liner blanks

A technology of blanks and fixtures, which is applied in the field of fixtures for continuous processing of bushing blanks, can solve the problems of continuous operation, time-consuming and laborious loading and unloading, and low processing efficiency, so as to improve cutting processing efficiency, continuous processing, and firm clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A fixture suitable for continuous processing of bushing blanks of the present invention will be further described in detail below in conjunction with the accompanying drawings.

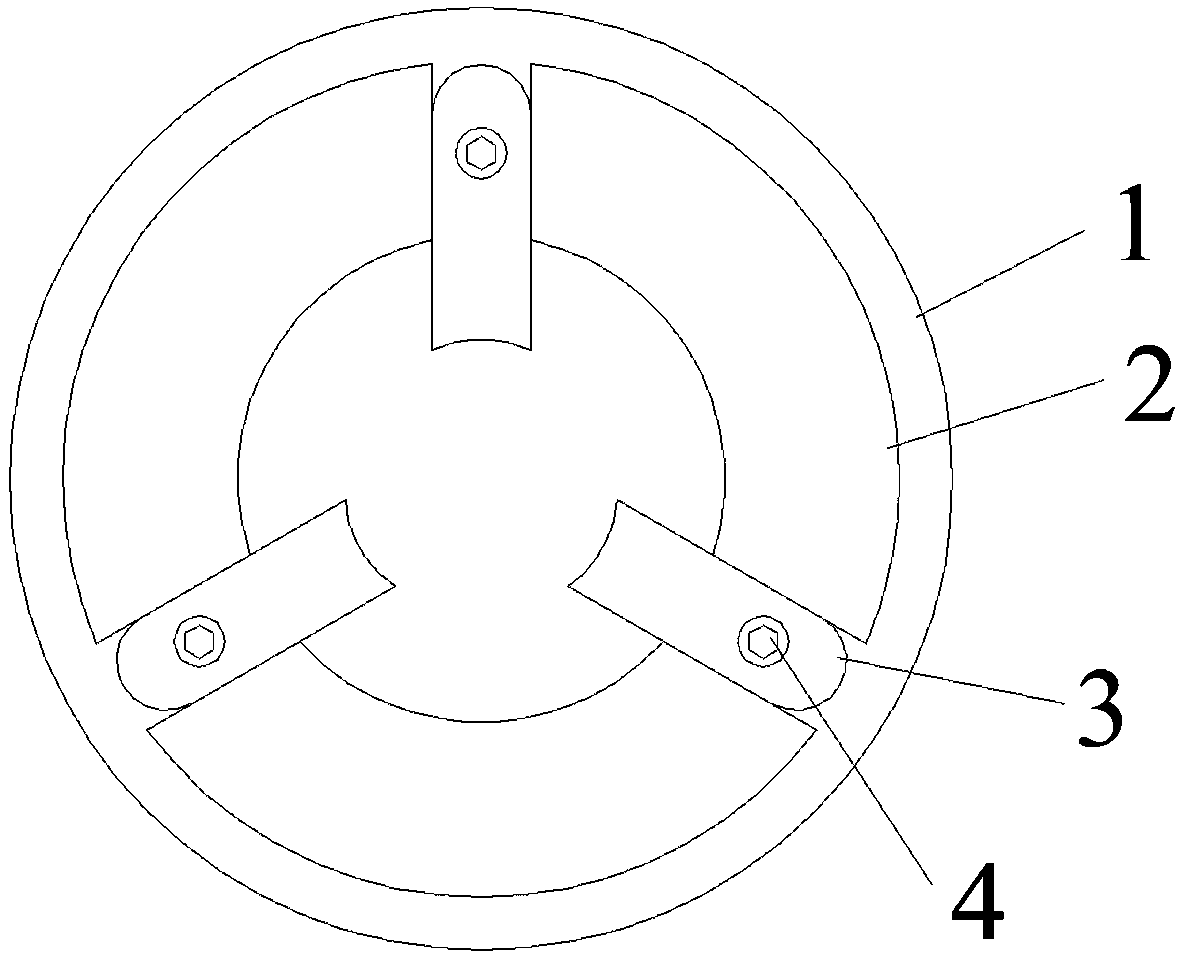

[0009] figure 1 The shown fixture is suitable for the continuous processing of bushing blanks, including chuck 1 and movable jaw 3. Chuck 1 is set as a circular ring, and three ring-shaped fan-shaped chucks 2 are fixed on chuck 1, and chuck 2 It is the same center as the chuck 1 and is evenly distributed on the chuck 1. The movable jaws 3 are respectively set between every two chuck tables 2, and the pneumatic interface 4 is set on the movable jaws 3. The inner end of the movable jaws 3 is set to arc.

[0010] When in use, install the fixture on the machine tool, connect the compressed air, control the machine tool to open the movable jaws 3, put the bush blank and then control the machine tool to make the movable jaw 3 clamp the blank, and start the machine tool to drive the fixture and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com