Exhaust anti-spilling device

An exhaust machine and screw technology, applied in the field of chemical equipment, can solve the problems of reducing volatile matter discharge, affecting product quality, and product inclusion of black particles, etc., to achieve the effect of preventing backflow, increasing the exposed area of materials, and strengthening the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with accompanying drawing and embodiment, and the embodiment that enumerates is the example that practical operation is verified in the large-scale trial production, therefore is easy to be mastered by those skilled in the art. If some changes are made on the basis of the present invention, the essence does not exceed the scope of the present invention, and the examples described are only to illustrate the present invention, and do not limit the present invention.

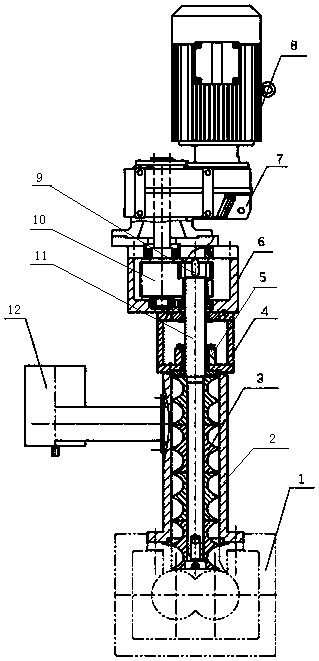

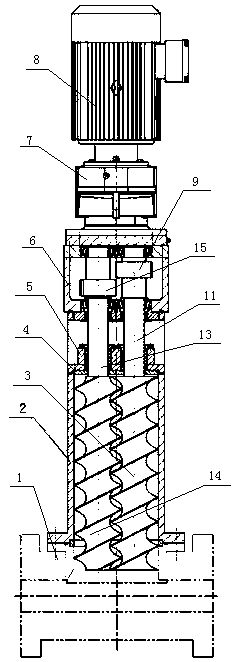

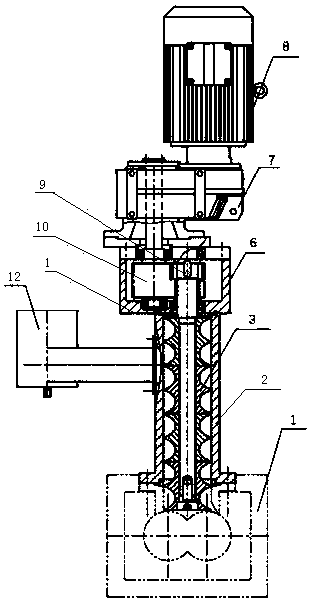

[0030] refer to Figure 1-2 , Embodiment 1, the present embodiment is an exhaust anti-overflow device, which includes an exhaust machine, a distribution box 6, a speed reducer 7 and a motor 8, and the lower end of the exhaust machine is fixedly connected with the open barrel 1 at the upper end of the main machine , and communicate with the main machine through the opening barrel 1 at the upper end of the main machine, the upper end of the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com