Preparation method of pure amino plastic bocce

A manufacturing method and technology of pure amino, which is applied in the field of manufacturing pure amino plastic throwing balls, can solve problems such as poor bonding, unstable center of gravity, cracking strength, etc., and achieve precise density control process, excellent center of gravity stability, avoiding direction The effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

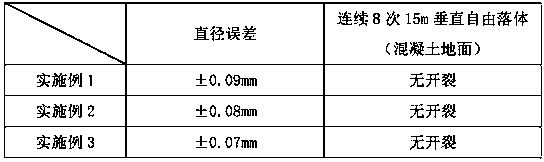

Examples

Embodiment 1

[0019] Embodiment 1, a kind of manufacture method of pure aminoplastic bocce ball, the method of the present invention comprises:

[0020] Cold-pressed star cake: put the amino molding compound in the star cake mold, pressurize at room temperature, the pressure is 60bar, keep the pressure for 1 second, and take out the product from the mold to become the star cake.

[0021] Color matching and pressing blank balls: first add the measured amino molding compound into the blank mold, place the pressed star cake on the surface of the amino molding compound according to the rules, then turn on the press, and the press reaches the set After the pressure is kept for 8 seconds, the mold is released, and the set pressure is 100 bar, that is, one half of the rough ball is obtained, and the other half of the rough ball is made in the same way, and the combination is a rough ball.

[0022] Preheating: Place the rough ball in a high-frequency preheating machine, preheat for 15 seconds with ...

Embodiment 2

[0025] Embodiment 2, a kind of manufacture method of pure aminoplastic bocce ball, the method of the present invention comprises:

[0026] Cold-pressed star cake: put the amino molding compound in the star cake mold, pressurize at room temperature, the pressure is 60bar, keep the pressure for 1.5 seconds, and take out the product from the mold to become the star cake.

[0027] Color matching and pressing blank balls: first add the measured amino molding compound into the blank mold, place the pressed star cake on the surface of the amino molding compound according to the rules, then turn on the press, and the press reaches the set The pressure is maintained for 9 seconds and the mold is released. The set pressure is 100 bar, that is, one half of the rough ball is obtained, and the other half of the rough ball is made in the same way, and the combination is a rough ball.

[0028] Preheating: Place the rough ball in a high-frequency preheating machine, preheat for 30 seconds wit...

Embodiment 3

[0032] Cold-pressed star cake: put the amino molding compound in the star cake mold, pressurize at room temperature, the pressure is 60bar, keep the pressure for 2 seconds, and take out the product from the mold to become the star cake.

[0033] Color matching and pressing blank balls: first add the measured amino molding compound into the blank mold, place the pressed star cake on the surface of the amino molding compound according to the rules, then turn on the press, and the press reaches the set After the pressure is kept for 10 seconds, the mold is released, and the set pressure is 100 bar, that is, one half of the green ball is obtained, and the other half of the green ball is made in the same way, and the combination is a green ball.

[0034] Preheating: Place the rough ball in a high-frequency preheating machine, preheat for 45 seconds with a current of 0.2A (adjusted according to the ambient temperature), and the preheating is completed.

[0035] Curing molding: put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com