Automatic assembly tool for quick joint of drainage pipeline of sunroof of SGM Weilang

A drainage pipeline and assembly tooling technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as customer complaints, employee operation errors, and low production efficiency, so as to prevent inaccurate installation positions and avoid wrong directions , The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

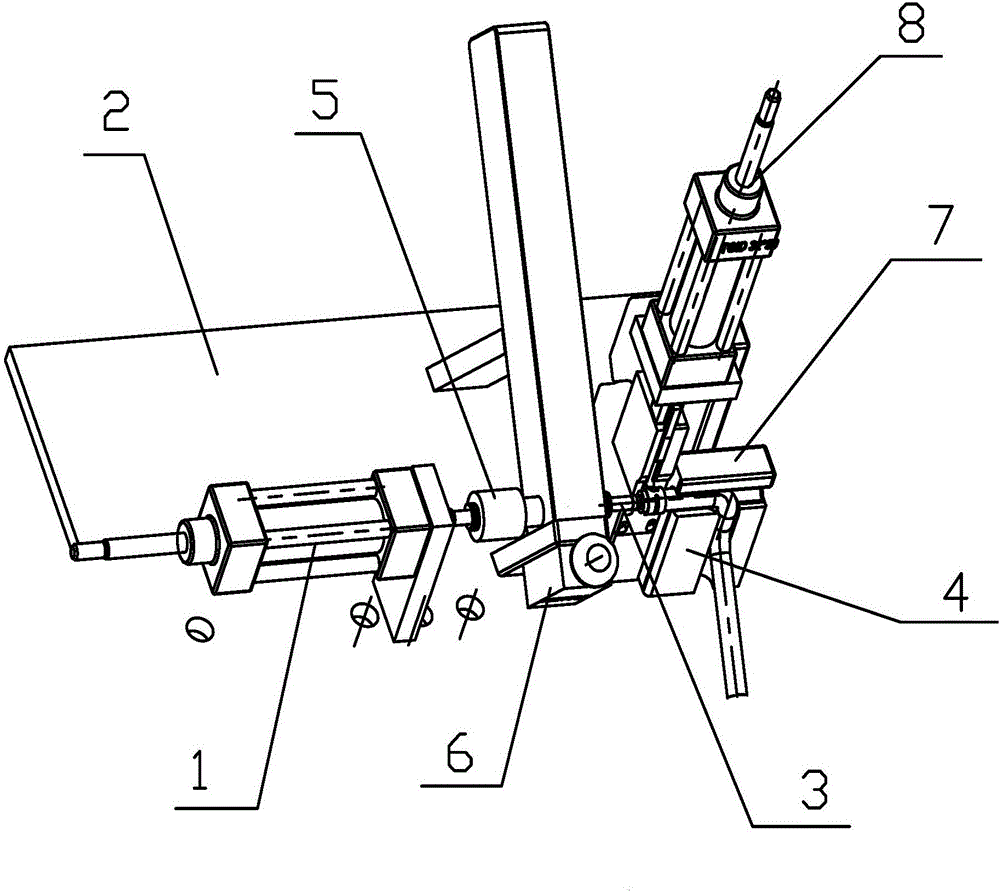

[0012] An automatic assembly tooling for quick joints of SGM Weilang skylight drainage pipes, including a bottom plate 2, on which a profiling 7, a horizontal cylinder 1 and a vertical cylinder 8 are installed, and between the profiling 7 and the horizontal cylinder 1 is installed Slide 3 and metal slider 4.

[0013] An adjusting rod 6 is installed between the slideway 3 and the horizontal cylinder 1 .

[0014] A limit block 5 is installed between the adjusting rod 6 and the horizontal cylinder 1 .

[0015] The horizontal cylinder 1 is used to open or close the elastic clamp, and the vertical cylinder 8 is used to push the quick connector to fit to the specified inner diameter of the hose. The profiling 7 is used to limit the shape of the rubber hose to ensure the consistency of the angle of the assembled quick connector.

[0016] Put the elastic clamp at the limit position of the clamp of the horizontal cylinder 1, start the horizontal cylinder 1, and the clamp is opened; p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com