Sintering pallet grate-layer material grading material arrangement device and method

A technology of sintering trolley and material distributing device, which is applied in the field of metallurgy, can solve problems such as poor sintering efficiency, achieve the effects of reducing power consumption, uniform air distribution, and maintaining effective ventilation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

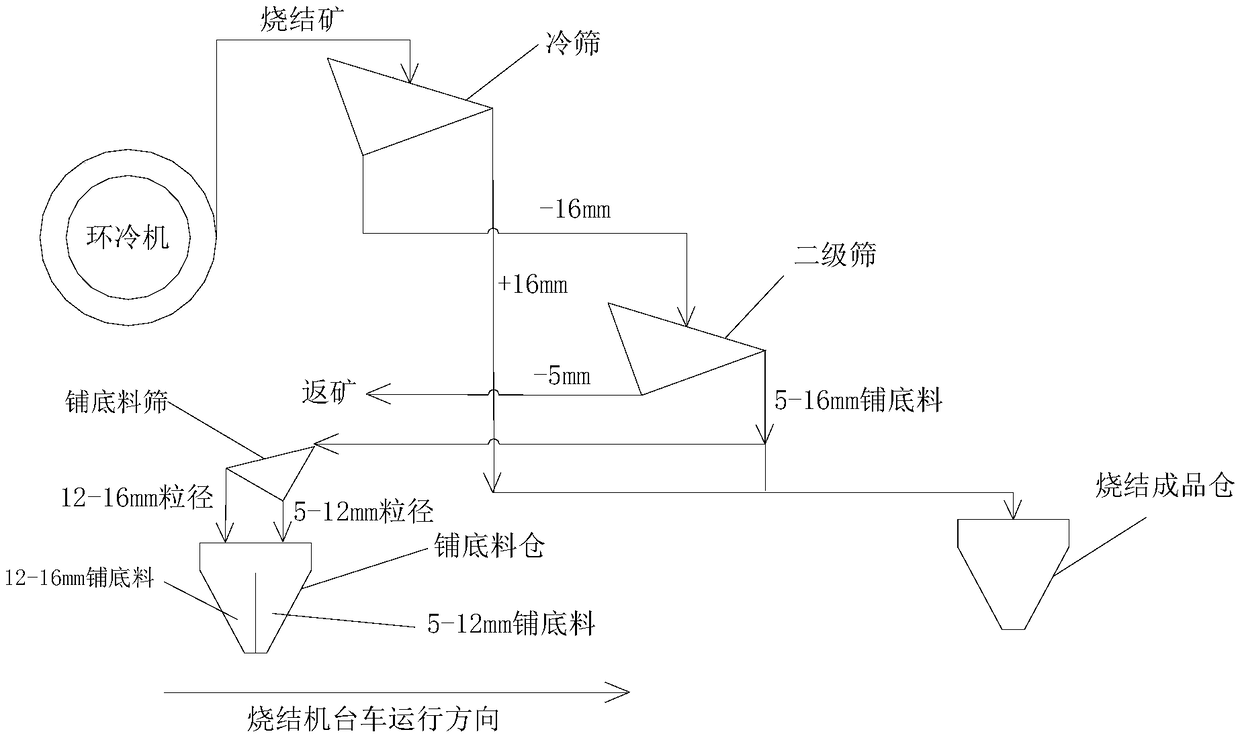

[0032] Such as figure 1 As shown, the sintering trolley bottom material classification distribution device of the present invention comprises:

[0033] Ring cooler; process sinter bottom material with a certain size and thickness;

[0034] The cold screen is arranged downstream of the annular cooler and connected to the outlet of the annular cooler; the grain size of the cold screen is 16mm, and the sintered ore of a certain grain size and a certain thickness processed by the annular cooler is filtered, and the granular The bottom material with a diameter of more than 16mm is filtered out and sent to the sintered product bin; the bottom material with a particle size of less than 16mm is filtered out and sent to the secondary material sieve;

[0035] The secondary ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com