Remote industrial site management system and method based on industrial main-machine interface

An industrial human-machine interface and remote monitoring technology, which is applied in the general control system, control/regulation system, sequence/logic controller program control, etc., can solve the problem of no effective use of on-site data, lack of control, data processing and display Single method and other problems, to achieve the effect of convenient operation and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

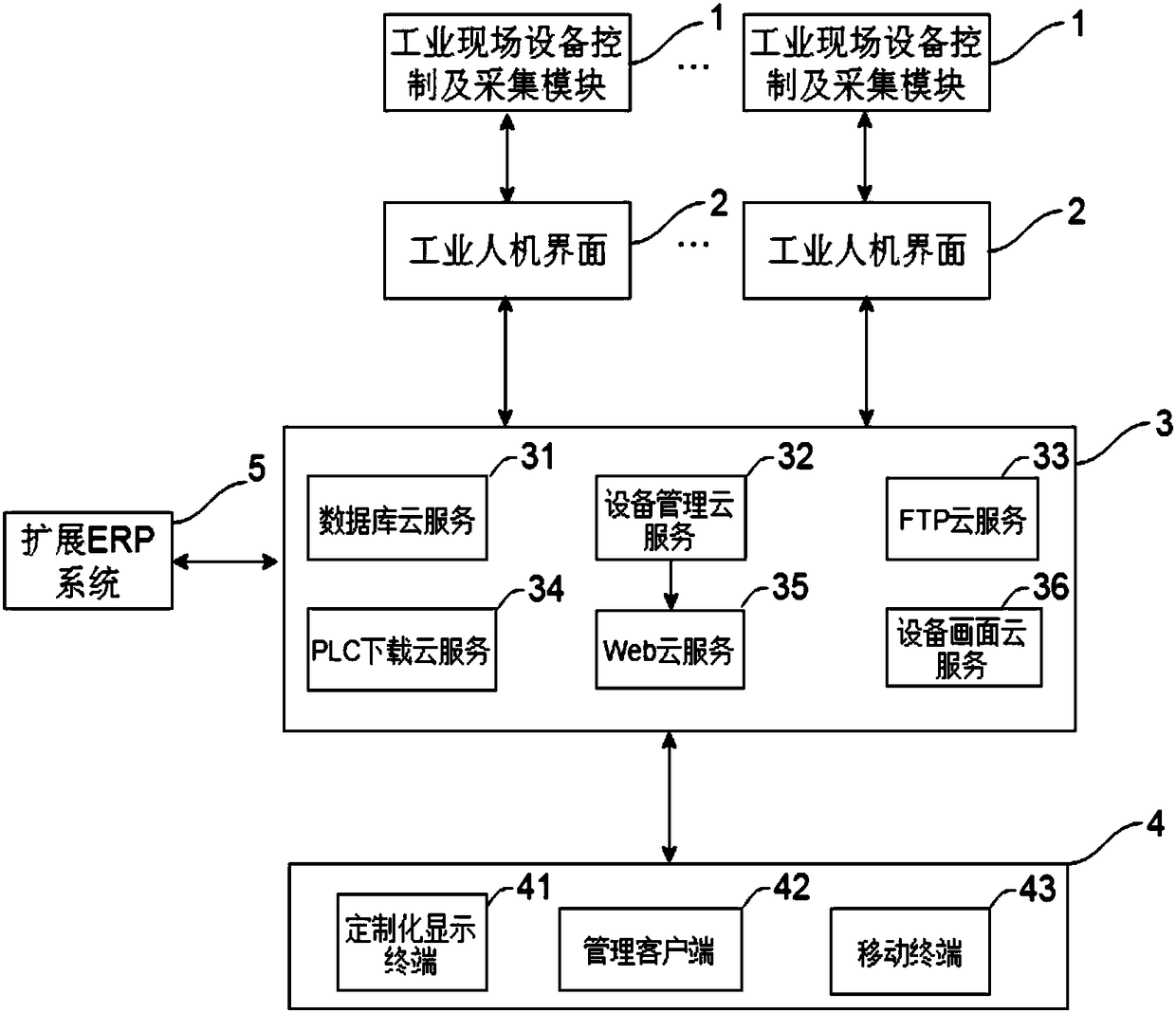

[0044] figure 1 It is a system architecture diagram of an industrial field remote monitoring and management system based on an industrial man-machine interface according to the present invention. The industrial field remote monitoring and management system based on the industrial man-machine interface mainly includes: at least one group of industrial field equipment control and data acquisition module 1 (including but not limited to programmable logic controller PLC); industrial man-machine interface (HMI) 2; Cloud service module 3; customer management and monitoring terminal module 4; and ERP system 5 that can be docked and expanded.

[0045]The industrial field device control and data acquisition module 1 and HMI 2 communicate through the field serial bus, Ethernet or CAN bus using a dedicated communication protocol. The industrial field device control and data acquisition module 1 collects the field device parameters and sends them to HMI 2. HMI 2 writes setting parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com