Temperature control device for microtube extrusion

A technology of extrusion temperature and control device, which is applied in the direction of metal extrusion control equipment, metal extrusion, manufacturing tools, etc., can solve the problems of uneven size of extrusion pipes, shortening the service life of extrusion dies, over-burning, etc. Achieve the effect of reducing internal and surface defects, solving low service life and ensuring size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

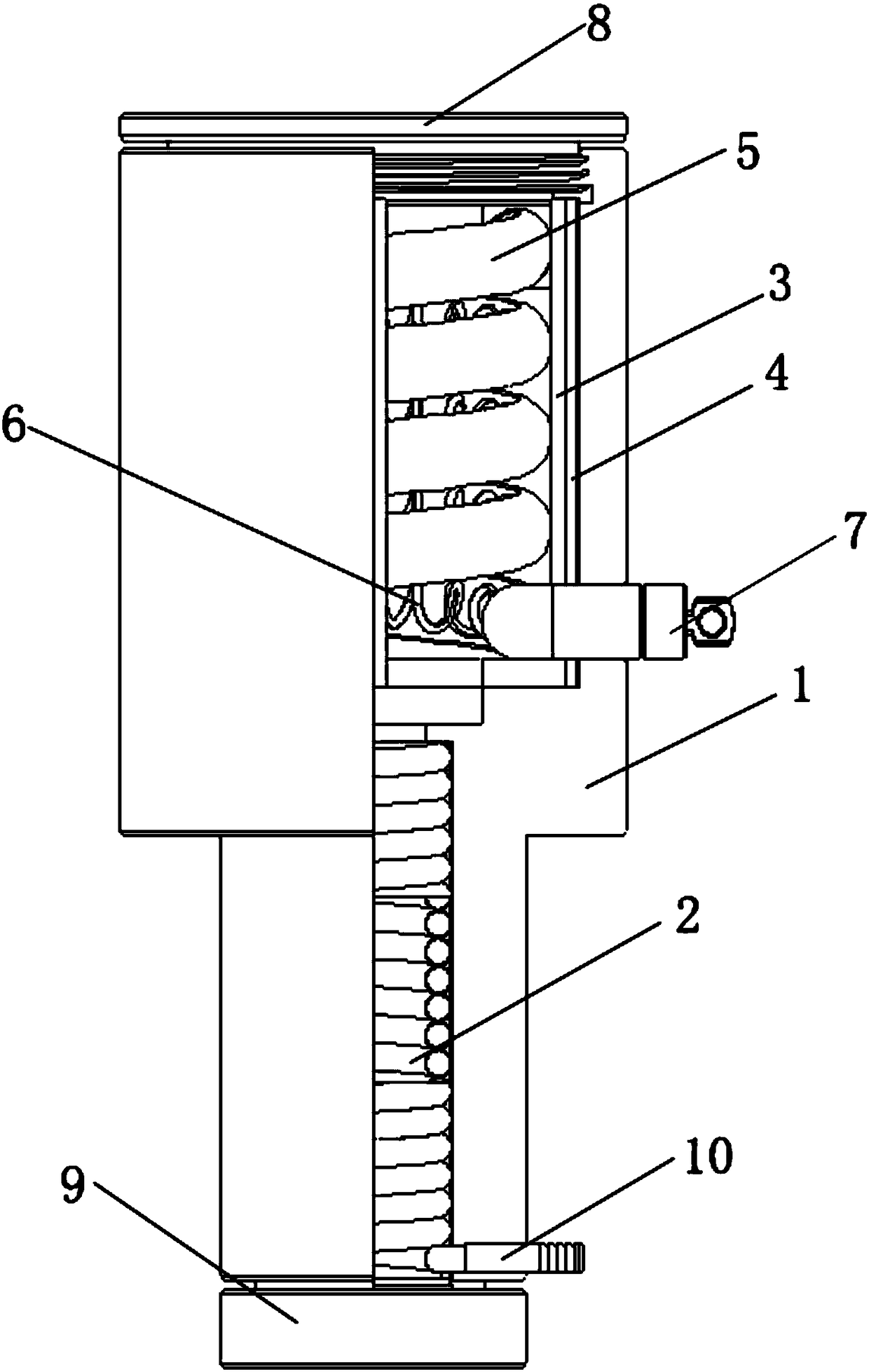

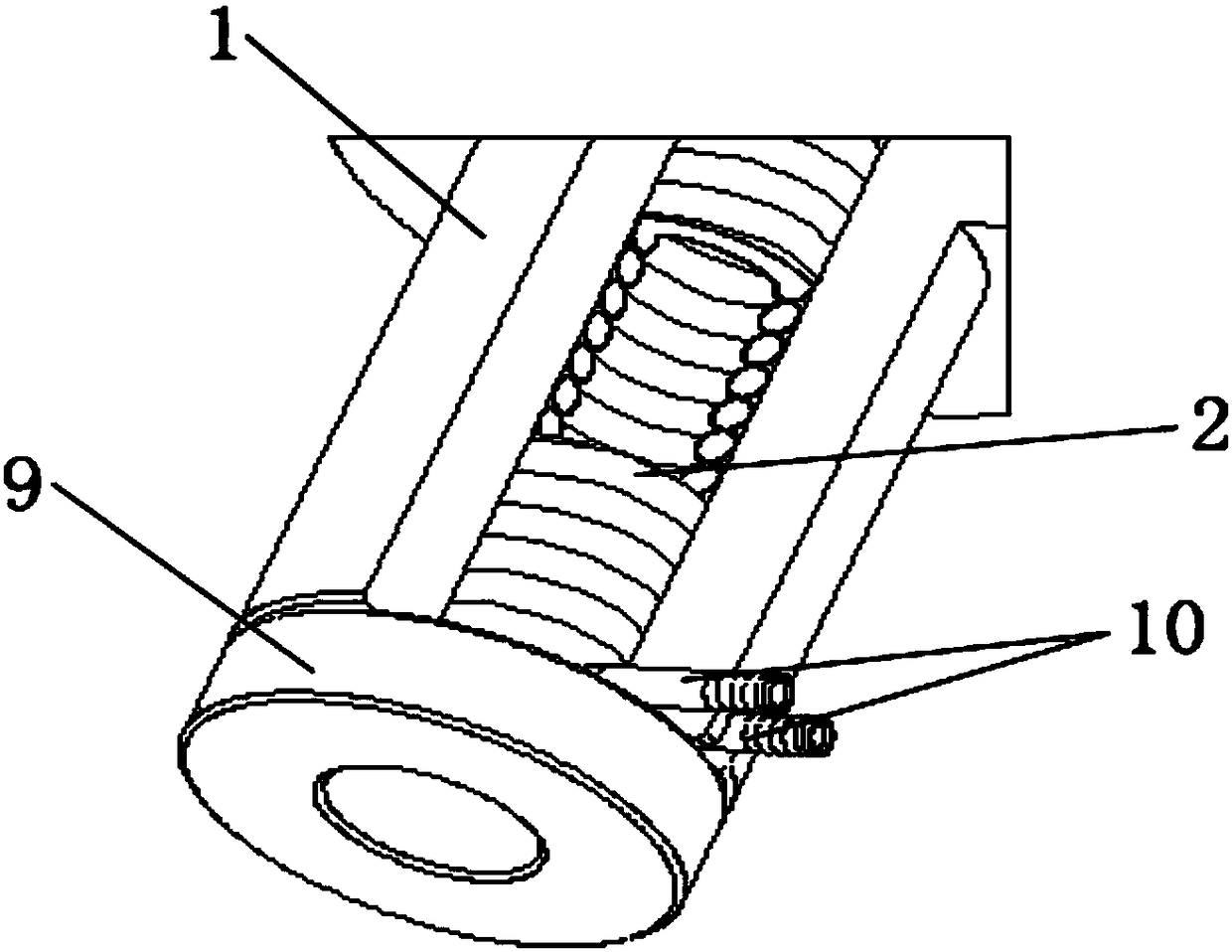

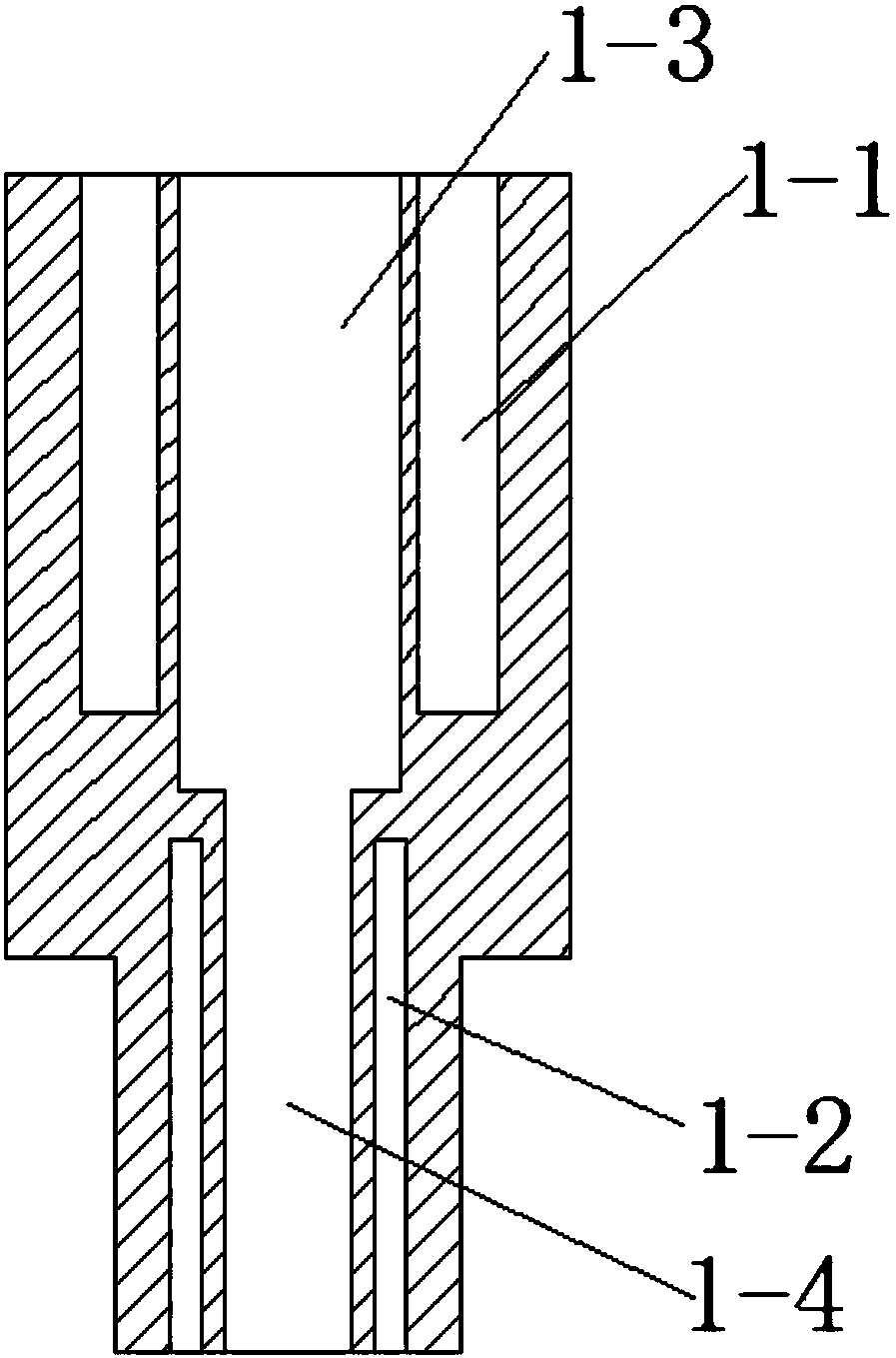

[0025] like figure 1 , figure 2 and image 3 As shown, the present invention includes a pipe sleeve 1, and the pipe sleeve 1 is provided with an extrusion channel for extruding a tube blank in the axial direction, and the extrusion channel is composed of interconnected heating channels 1-3 and cooling channels 1-4, The diameter of the heating channel 1-3 is greater than the diameter of the cooling channel 1-4, and a heating cavity 1-1 is arranged on the sleeve wall of the pipe sleeve 1 on the side of the heating channel 1-3, and the heating cavity 1 -1 is provided with a spiral tube 5, both ends of the spiral tube 5 pass through the heating chamber 1-1, and the spiral tube 5 is pierced with a tube for heating and extruding the tube blank to the hot extrusion temperature. Heating wire 6, both ends of the heating wire 6 pass through the spiral tube 5 to connect with the metal core of the electrical connector 7, the electrical connector 7 is fixed at the mouth of the spiral tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com