Mould for machining interior decorative plate of automobile door

A technology for interior decorative panels and car doors, applied in metal processing, etc., can solve problems such as worker scratches, and achieve the effects of strong drilling power, compact and simplified structure, and comprehensive functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

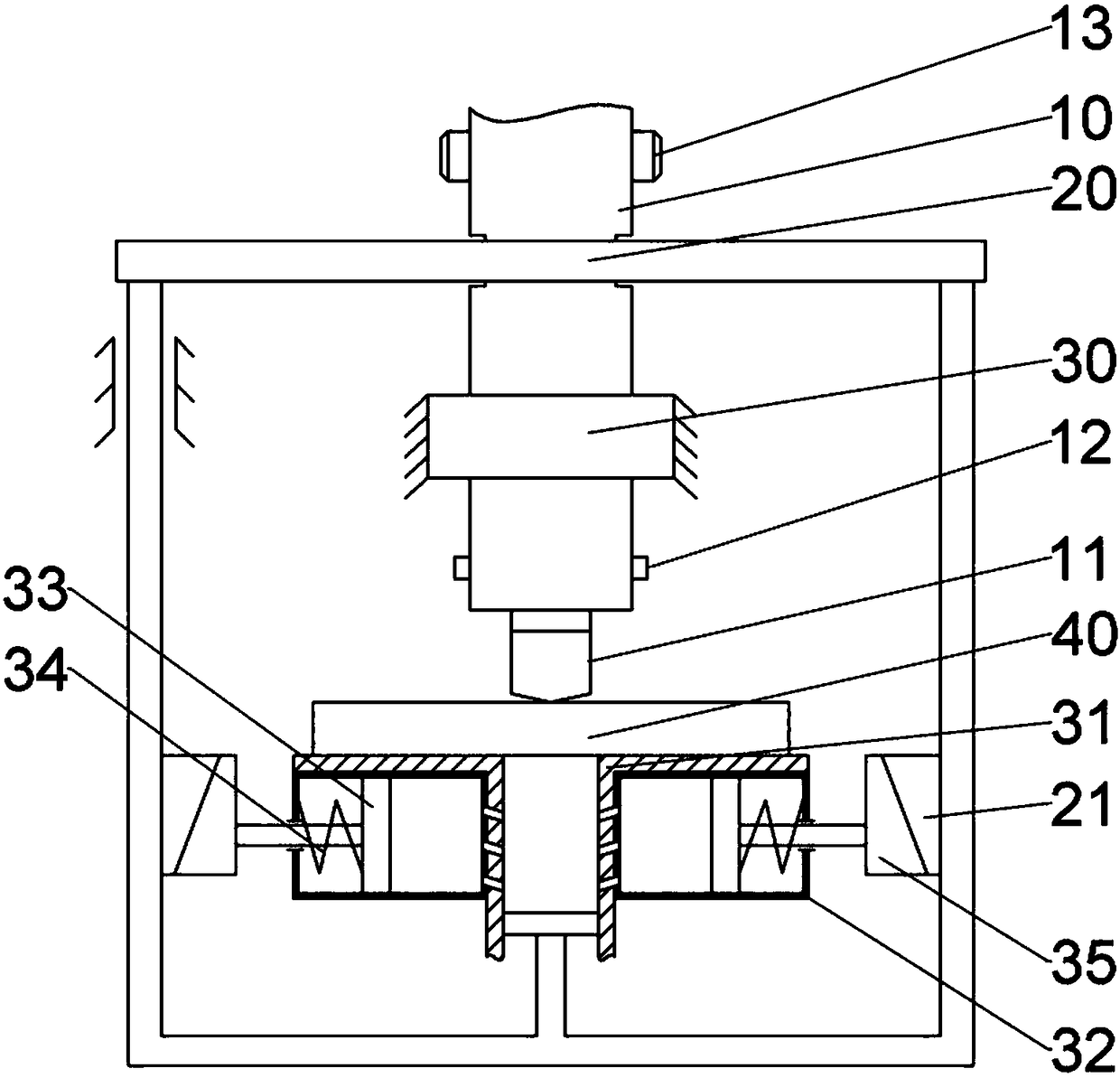

[0024] Basic as attached figure 1 Shown: a kind of mold for processing the interior trim panel of automobile door, comprises frame, is provided with main shaft 10, drive gear 13, drive frame 20, drill bit 11, support platform 31 and cylinder 32 from top to bottom on the frame.

[0025] Wherein the main shaft 10 comprises a spline section, a slot section, a thread section and a mounting section arranged in sequence from top to bottom; the drive gear 13 is driven by a motor and the inner hole is correspondingly provided with a spline groove, and the spline section and the drive gear 13 are splined. Key connection, the slot section is ring-shaped, and the upper end of the drive frame 20 is provided with a snap ring part, which is semicircular. Through the cooperation of the snap ring part and the slot section, the main shaft 10 drives the drive frame 20 to move axially, and the frame A nut sleeve 30 is arranged on the top, and the nut sleeve 30 is provided with an internal thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com