Straw shrinkage feeding device

A supply device and straw technology, which is applied in packaging, tubular objects, transportation and packaging, etc., can solve the problems of increased labor costs, low efficiency, and different positions of straws, and achieve stable and reliable efficiency, low error rate, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

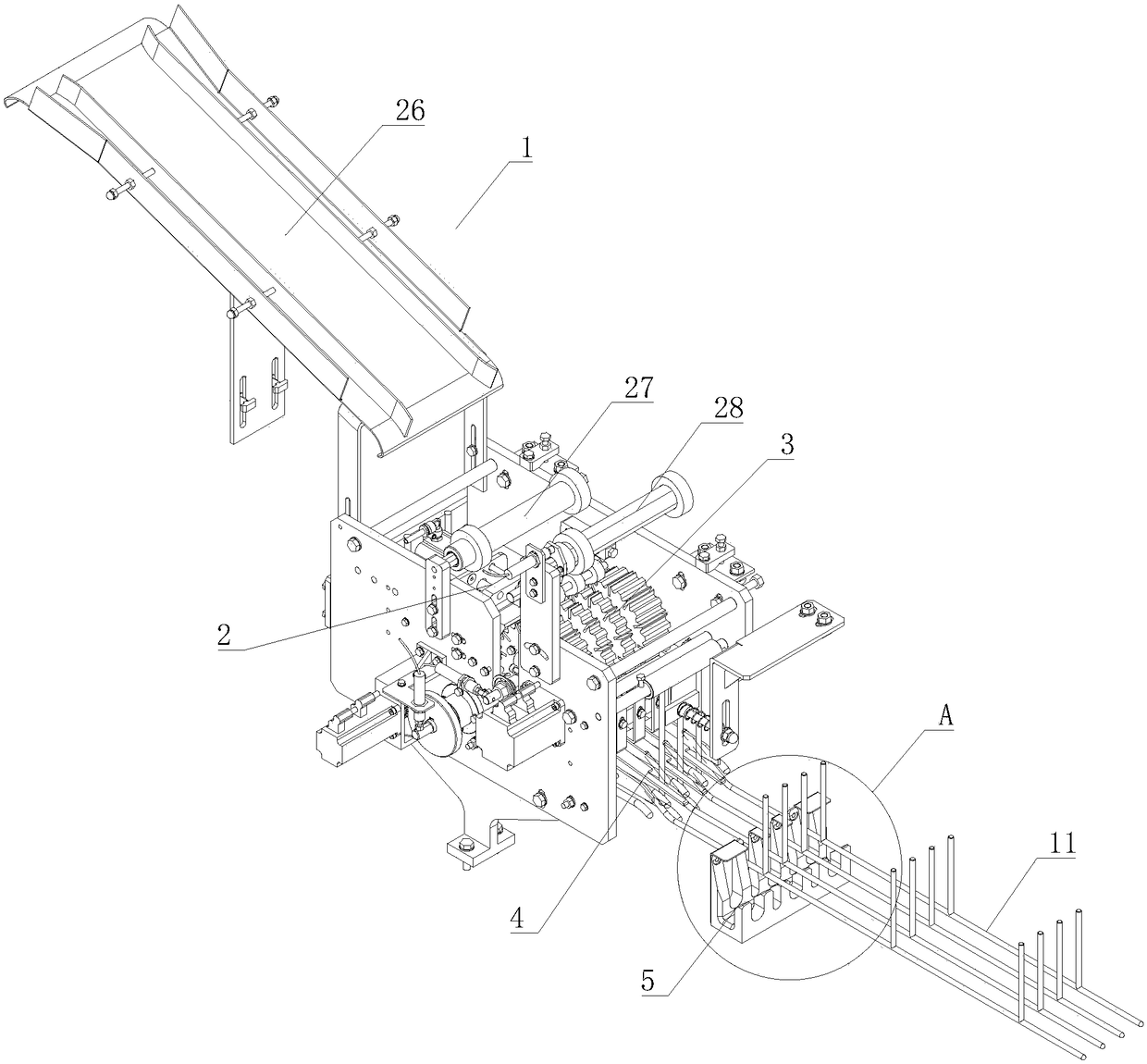

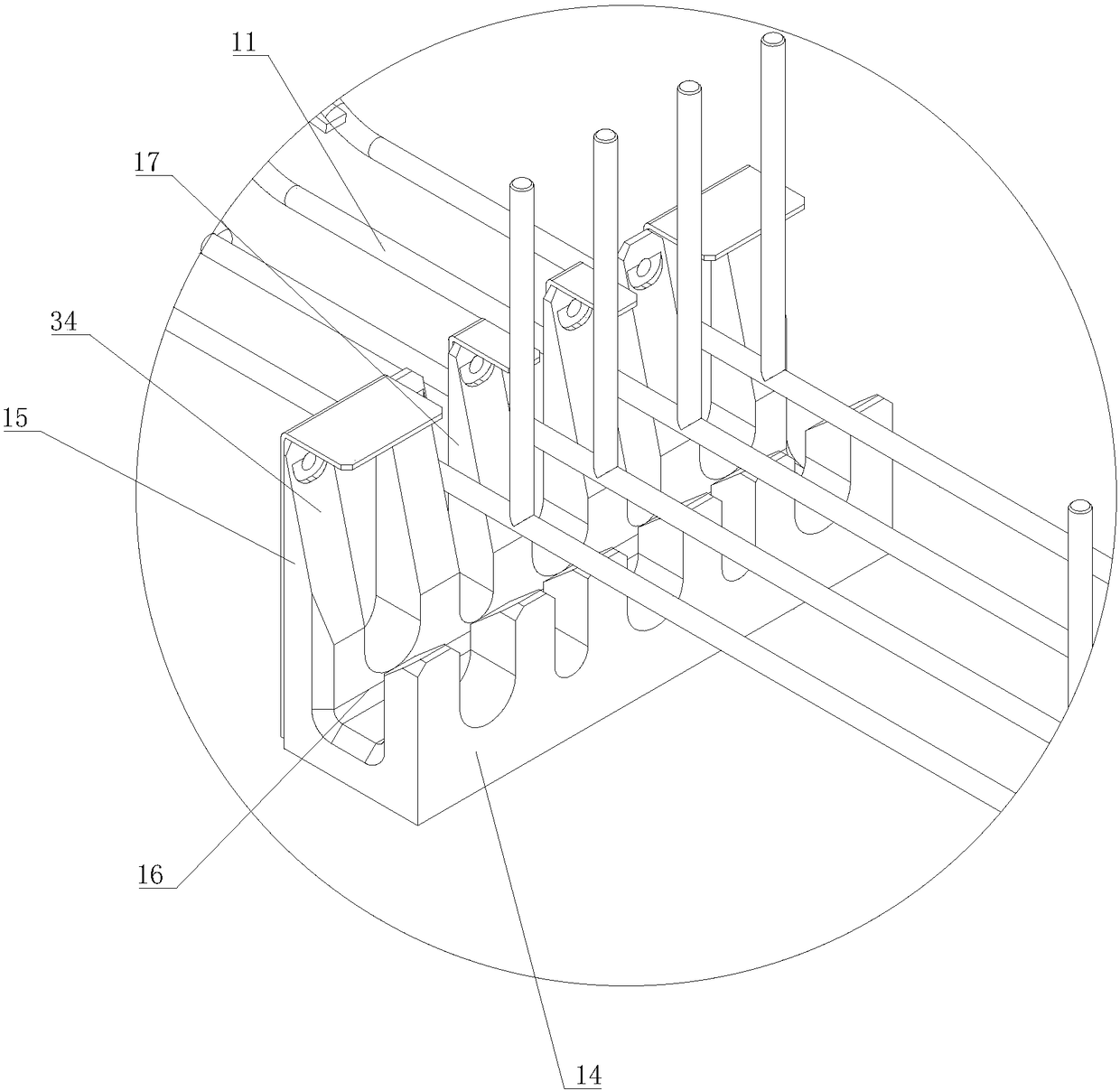

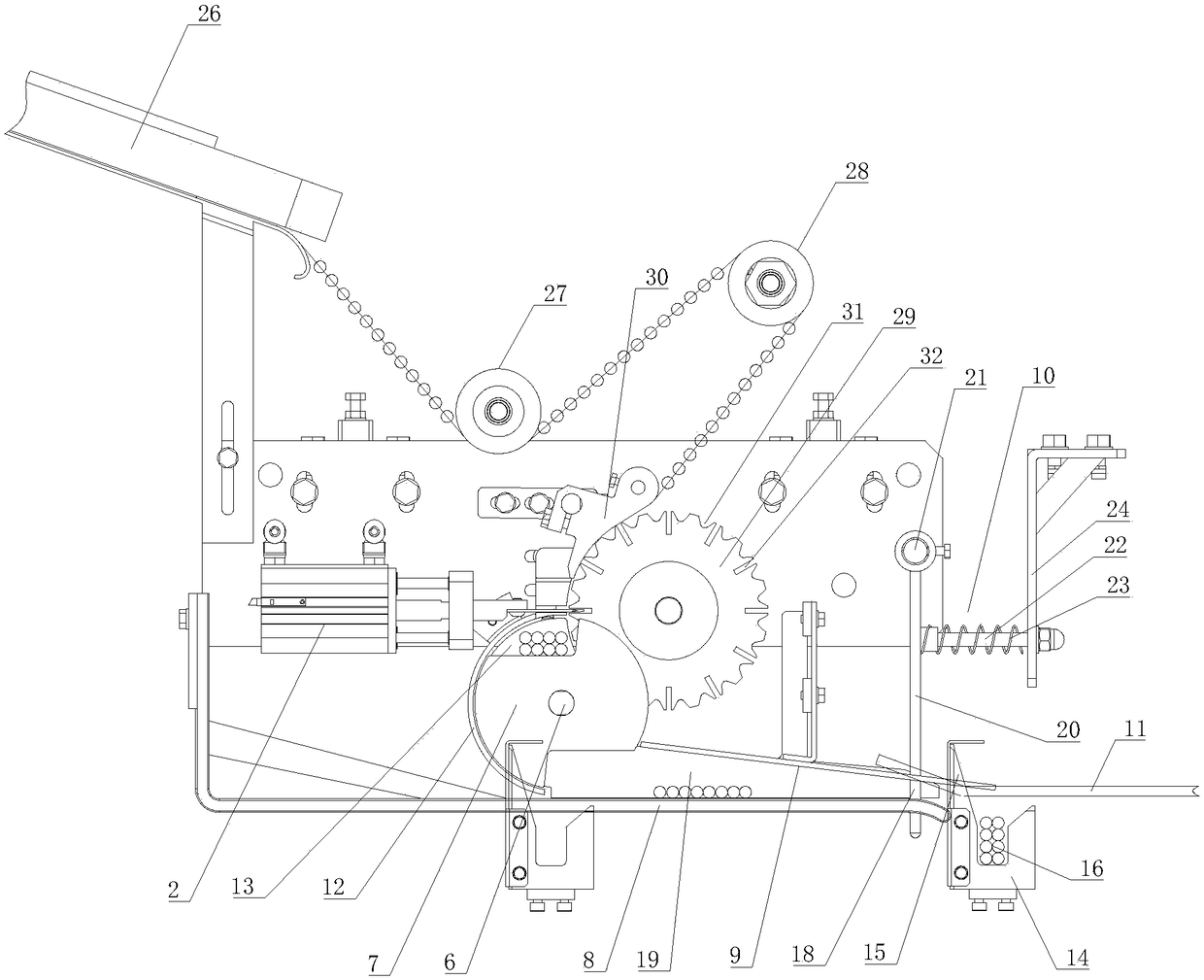

[0020] Such as Figure 1 to Figure 4 As shown, a straw shrinkage supply device includes a straw feeding assembly 1, a cutter assembly 2, a straw delivery assembly 3, a straw guide assembly 4, and a storage block 5; the straw guide assembly 4 includes a rotating shaft 6 and a dial 7 , straw bracket 8, straw limit frame 9, elastic pressure bar mechanism 10, straw pressure bar 11, guide plate 12; Described dial 7 is provided with two symmetrically arranged dial grooves 13; Described straw holder The frame 8 is made up of a plurality of bracket bars arranged in parallel with each other; the storage block 5 is provided with a storage part 14 and a push tube part 15, and the storage part 14 is provided with a storage groove 16, and the push tube The part 15 is vertically arranged on the receiving part 14 and is positioned at the outer edge of the receiving groove 16, and the receiving part 14 is provided with a plurality of escape grooves 17 arranged in parallel; A guiding slope 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com