Vibration absorption steel wire inhaul cable for bridge

A technology for bridges and steel wires, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as lack of buffer protection, reduced service life, and coating damage, and achieve improved service life, reduced costs, and high corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

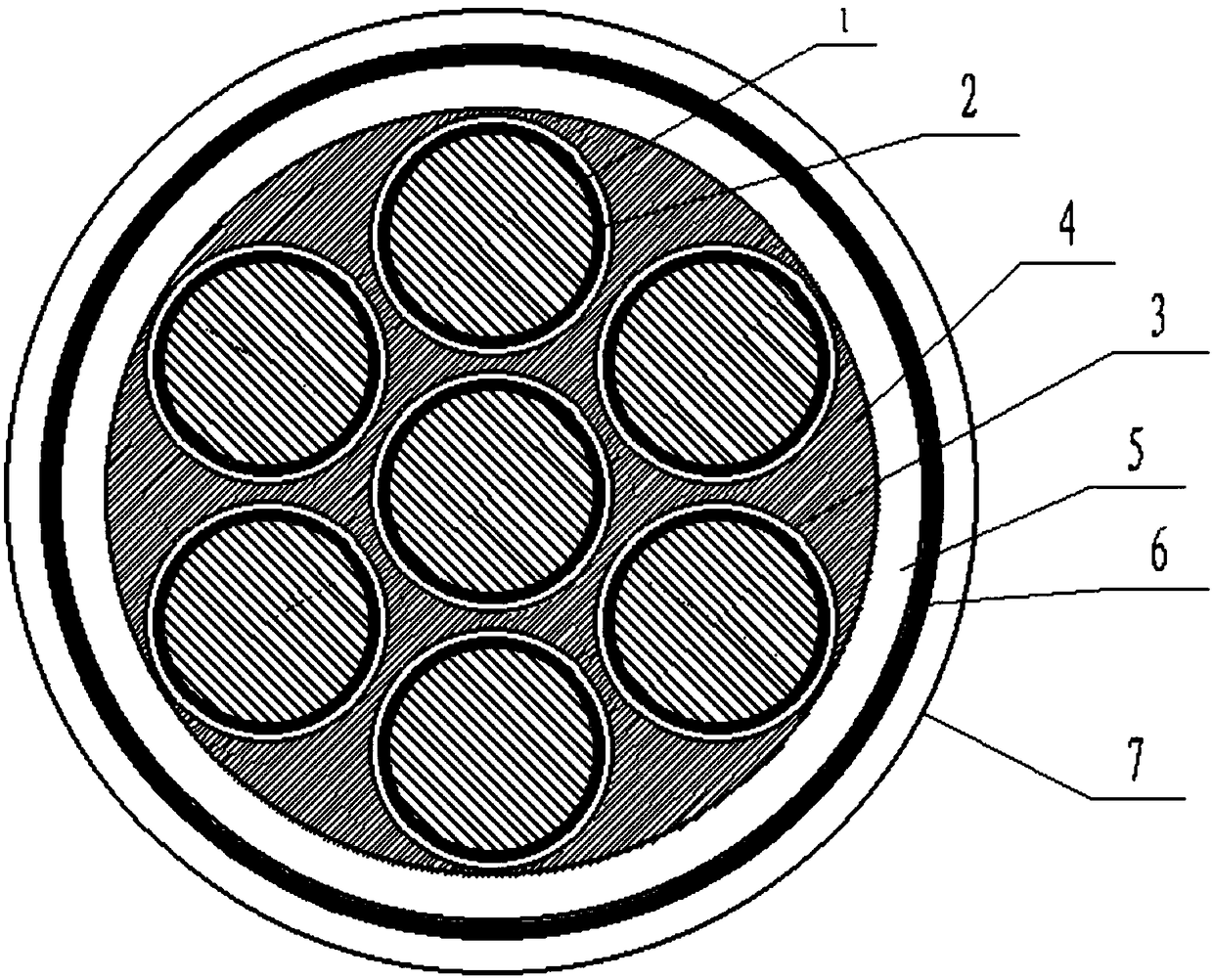

[0014] Such as figure 1 As shown, a steel wire cable for a bridge includes a plurality of smooth steel wires 1, the plurality of smooth steel wires 1 are arranged in a hexagonal close-packed manner, and the outer surface of the steel wires is coated with a particle layer 2 forming a rough surface, The particle layer is coated with a protective coating, and there is a foam shock absorbing material 4 between the multiple steel wires with the protective coating, and the outer layer is wrapped with a rigid shell 5 and a HDPE sheath 7, and the rigid shell 5 and the HDPE sheath 7 is provided with flame-retardant layer 6 between.

[0015] The specific processing method is as follows: first select the steel wire, the composition of the steel wire is: C: 0.32-0.58%, Si: 4.1-5.3%, Ti: 1.1-1.3%, Ni: 1.0-1.1%, Cr: 0.1-0.8%, Mo: 0.1-0.15%, Cu: 0.04-0.06%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com