An Intensive Stainless Steel Kitchen Sink

A kitchen sink, stainless steel technology, applied in water supply devices, mechanical equipment, multi-way valves, etc., can solve the problem of difficult to effectively use the floor cabinet space, and achieve the effect of simplifying the structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

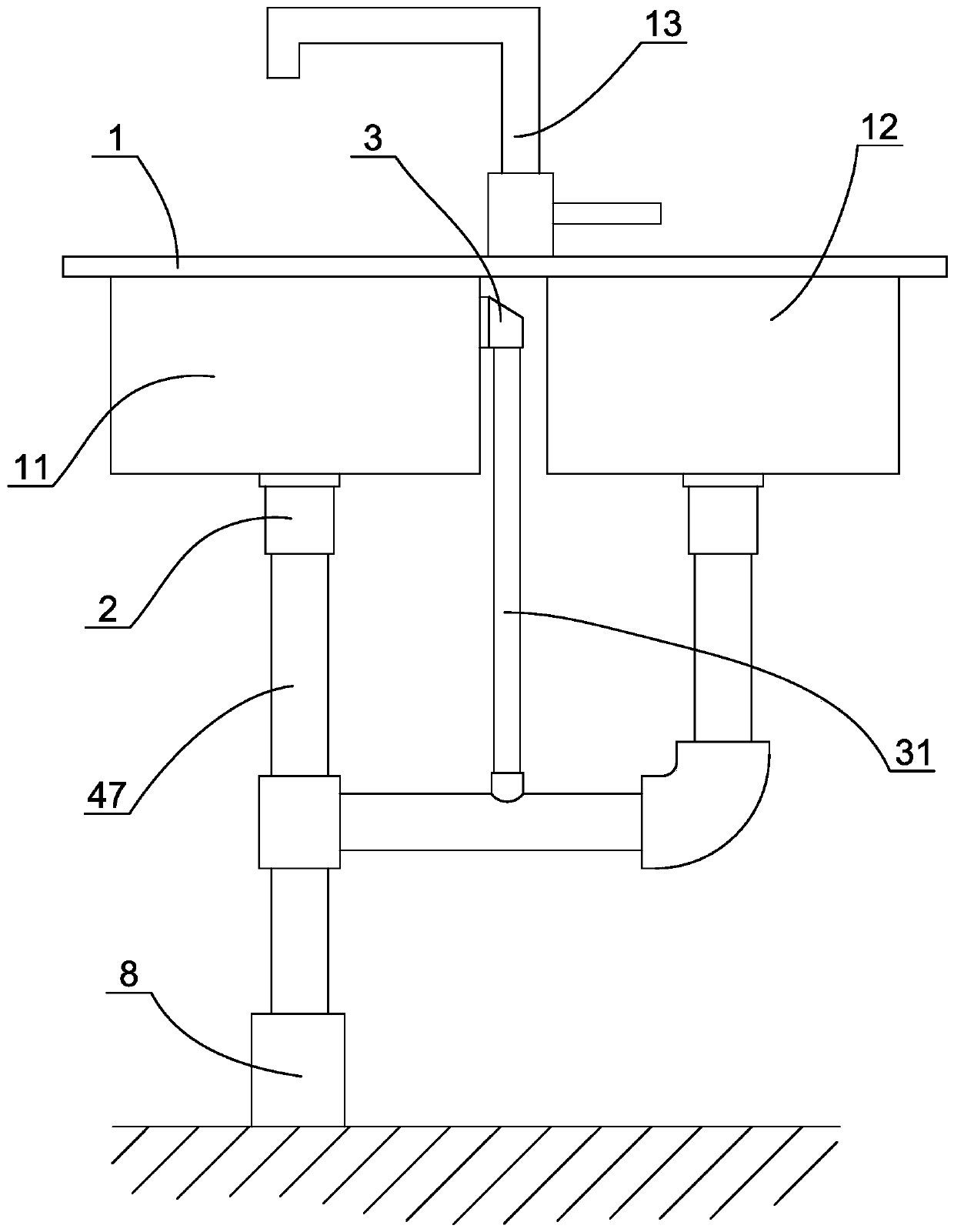

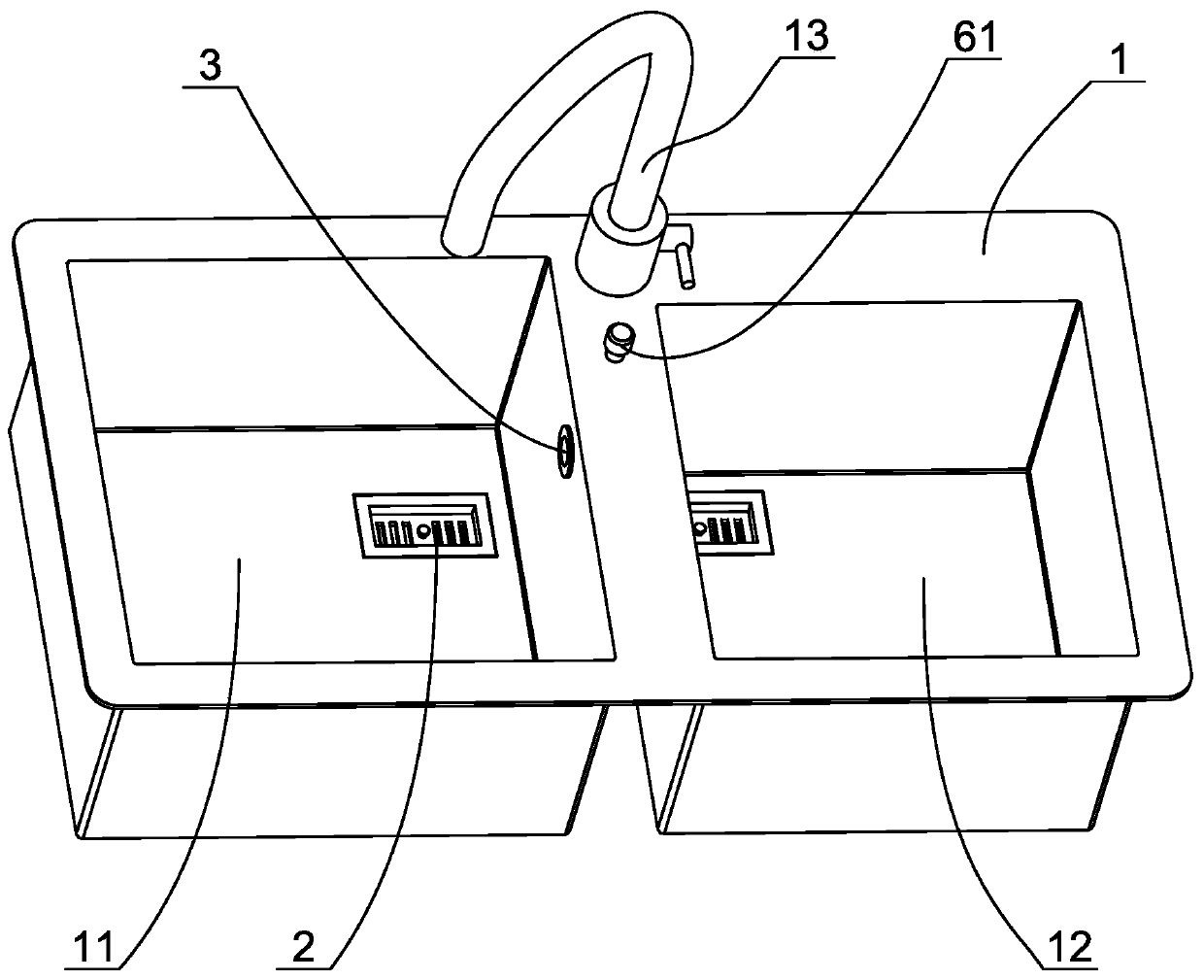

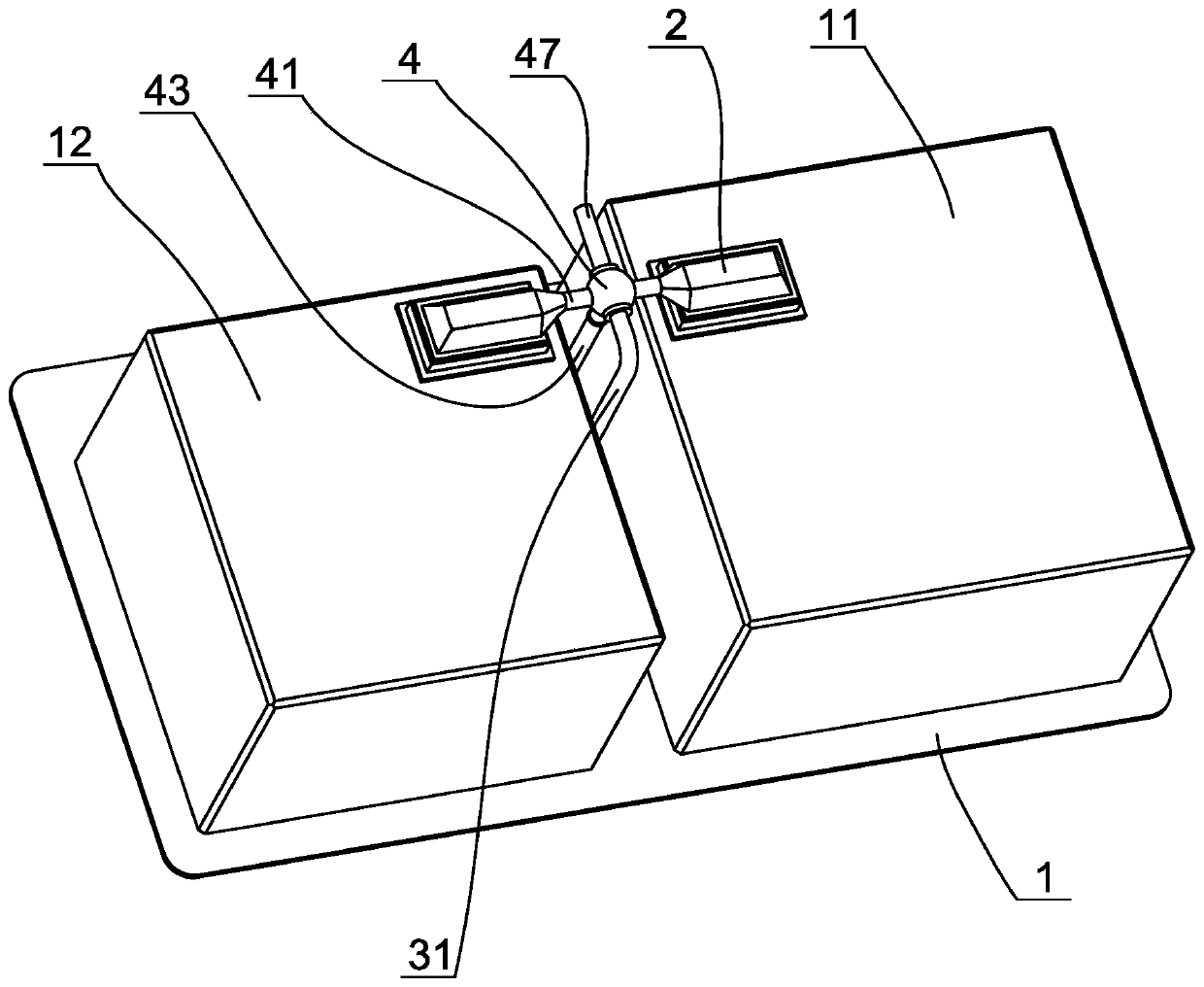

[0036] Such as figure 2 , image 3 , Figure 4 As shown, an intensive stainless steel kitchen sink includes a rectangular sink side 1, a main rectangular tank body 11 and a secondary rectangular tank body 12 which are integrally arranged on the side of the sink and arranged side by side. The water tap 13 that rotates, so that main, secondary rectangular tank body water supply. The bottoms of the main and auxiliary rectangular tanks are respectively provided with drains, and the drain joints 2 are arranged at the drains. An overflow hole is respectively arranged on the upper side of the side walls of the main and auxiliary rectangular tanks. The main and auxiliary rectangular tanks Overflow joints 3 are all set at the overflow holes. In addition, a four-way joint 4 and a three-way joint 5 are arranged in the gap between the outer sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com