Combined wall plate structure of lightweight composite material

A composite material and composite wall technology, applied in building components, building structures, noise absorbing devices, etc., can solve the problems of construction quality and progress, influence construction quality and progress, etc. The effect of interior space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In conjunction with the accompanying drawings, the present invention will be described in further detail.

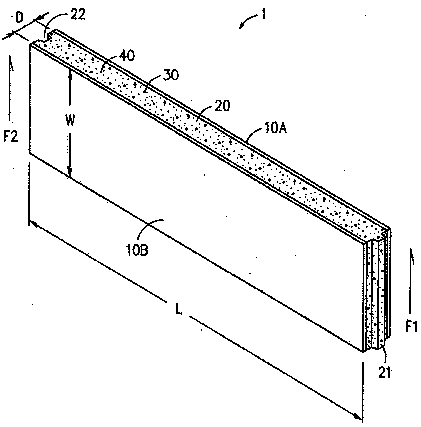

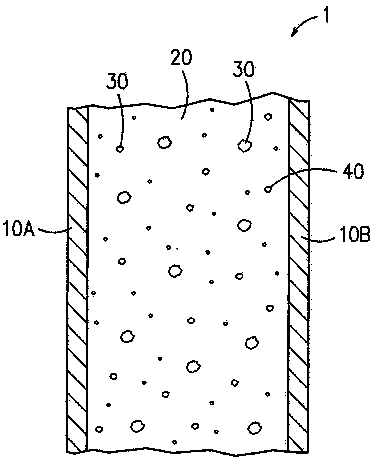

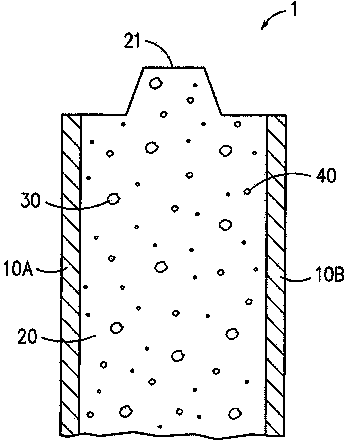

[0015] A combined wallboard structure of lightweight composite materials, comprising two boards 10A, 10B, lightweight cement 20, polystyrene particles 30 and lightweight filler 40, characterized in that: the two boards 10A, 10B are separated by a distance D; The cement 20 is arranged between the two boards 10A, 10B, one side is provided with a convex portion 21, and the convex portion 21 protrudes from the corresponding edge of the two boards 10A, 10B, and the other side is provided with a concave portion 22, and the concave portion 22 is recessed in the two boards. On the corresponding edges of the plates 10A, 10B, the shape of the concave portion 22 corresponds to that of the convex portion 21 . The protrusion 21 is a three-dimensional trapezoid with a length, and the length direction F1 of the protrusion 21 is parallel to the sides of the two plates 10A, 10B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com