Temperature-controllable fuel boiler

A water boiler and fuel technology, which is applied in water heaters, lighting and heating equipment, fluid heaters, etc., can solve the problems of inability to detect scale formation in the water tank, heat loss, cracking of the straight fire pipe water tank, etc., to improve self-sustainability. capacity and heating efficiency, the effect of reducing thermal stress, reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

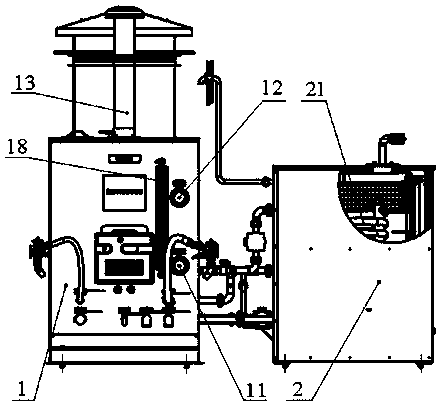

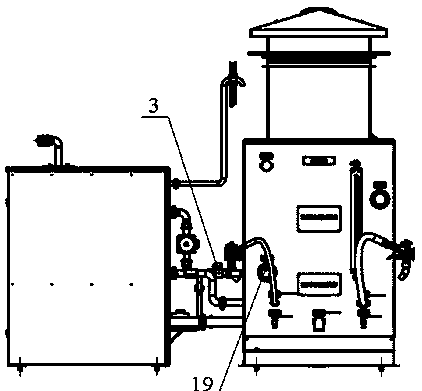

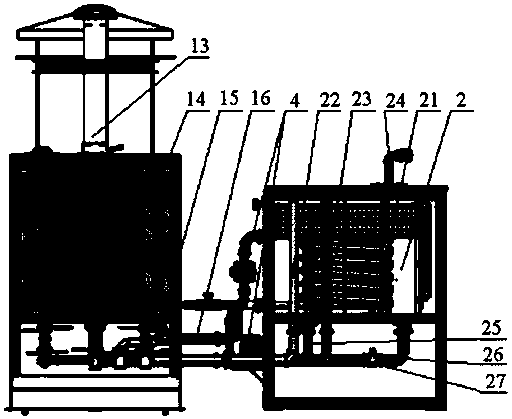

[0022] A temperature-controllable oil-fired water boiler is a normal pressure, energy-saving stainless steel water boiler, which includes a water boiler 1 and a water make-up tank 2 connected by pipelines. The working state of the water boiler and the water make-up tank is controlled by a PLC controller.

[0023] The boiling water furnace is an internal combustion, horizontal, two-pass diesel furnace. The heat insulation material of the furnace body is polyurethane and the fuel is diesel. The boiling water furnace has a size of 1600mm×800mm×1200mm and a capacity of 300L. The boiling water furnace includes a furnace body, a water storage tank 112 is arranged in the furnace body, a burner 14 is arranged under the water storage tank, and the water storage tank and the burner in the furnace body are placed in the furnace 113; the top of the furnace body is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com