Test device and method for evaluating anti-cracking sensitivity of pipeline steel in acid environment

An anti-cracking, pipeline steel technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of increasing difficulty and no longer applicable, and achieve the effect of comprehensive and reliable anti-cracking sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

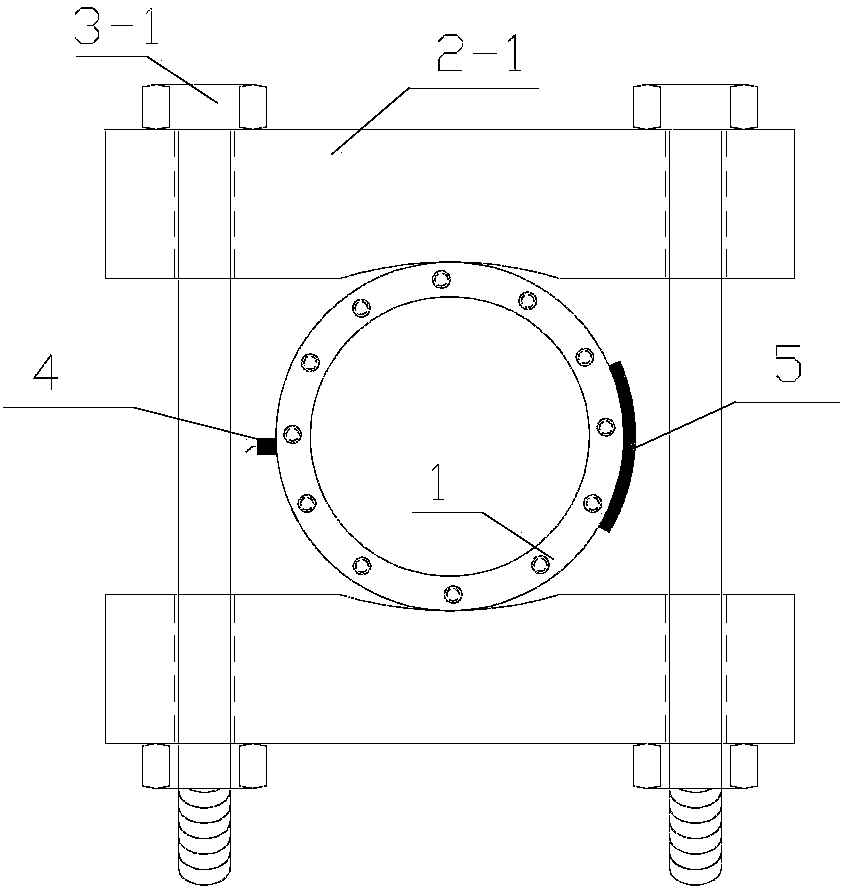

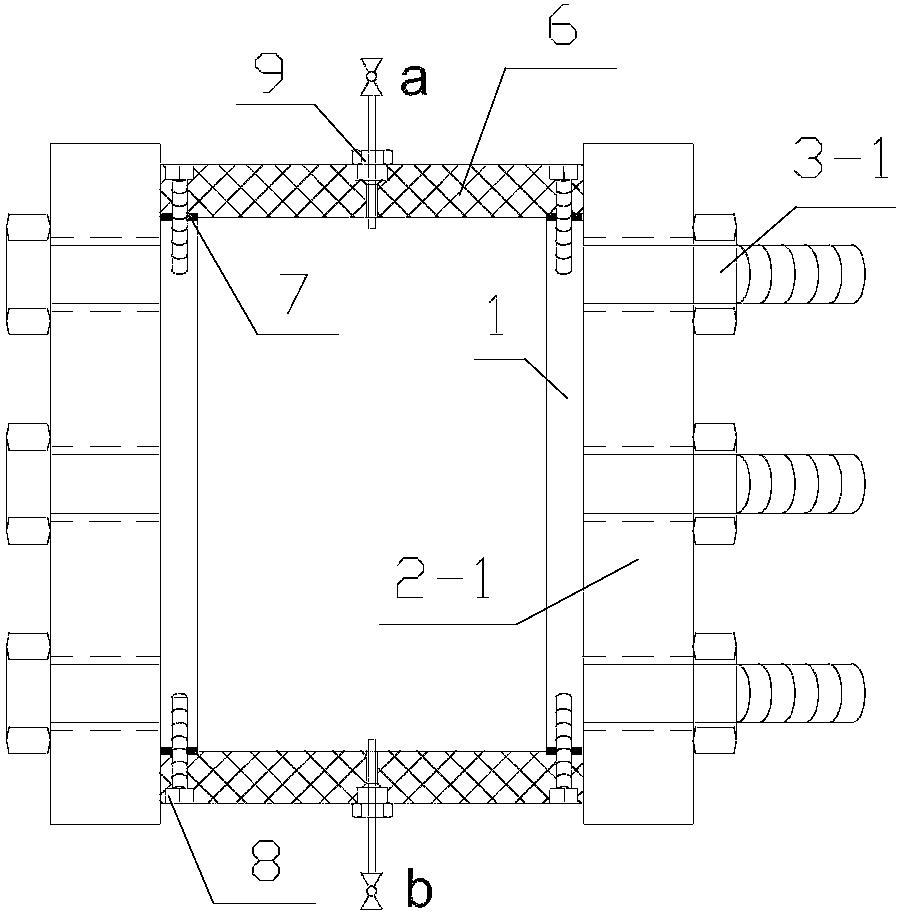

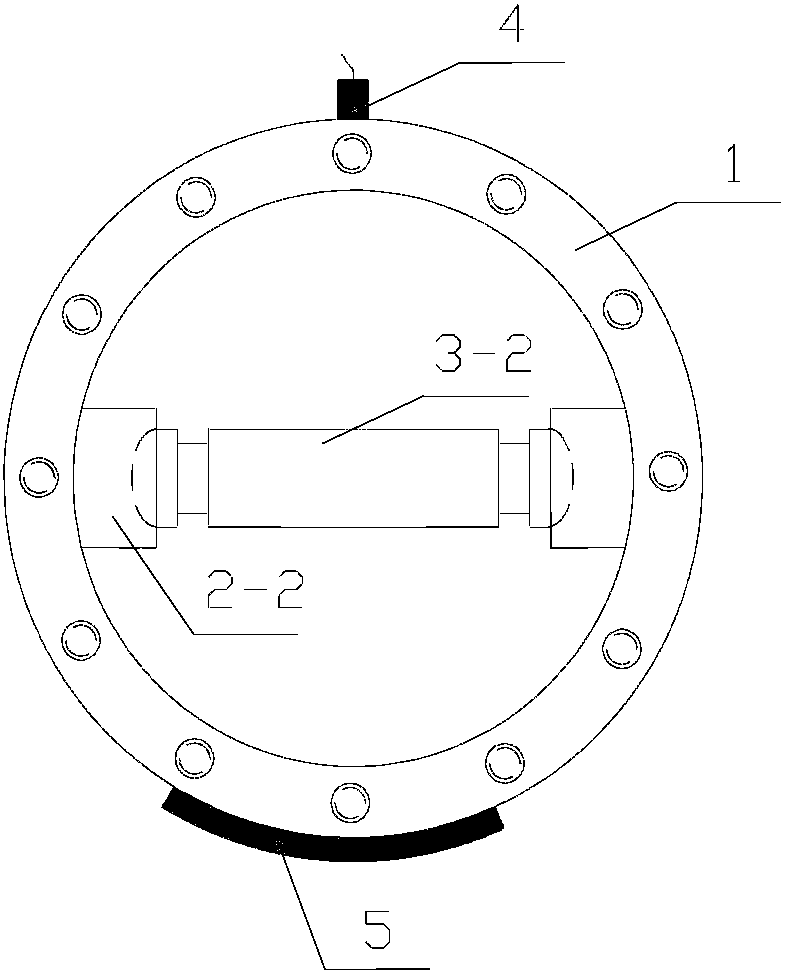

[0018] A test device for evaluating the susceptibility to cracking resistance of pipeline steel in an acidic environment using an annular pipe section, such as Figure 1 to Figure 4 As shown, it includes a ring-shaped pipe section loading component, a pipe end sealing component and a non-destructive testing component. The loading components are divided into external loading and internal loading. Among them: the external loading component includes a loading stop 2-1 and a fastener 3- 1. The internal loading component includes a loading bar 2-2 and a sleeve nut 3-2; the pipe end sealing component includes a sealing cover 6, a sealing ring 7, a fastening bolt 8, a gas-liquid inlet and outlet sealing component 9, and a valve a And b; the non-destructive testing component includes an ultrasonic detector and a hydrogen flux meter, the loading block 2-1 has an arc-shaped groove, and the loading block is fixed and disassembled by a fastener 3-1; loading The retaining bar 2-2 has a sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com