Veneer intensity pasting test device

A technology for testing devices and decorative panels, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., and can solve problems such as large deviations, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

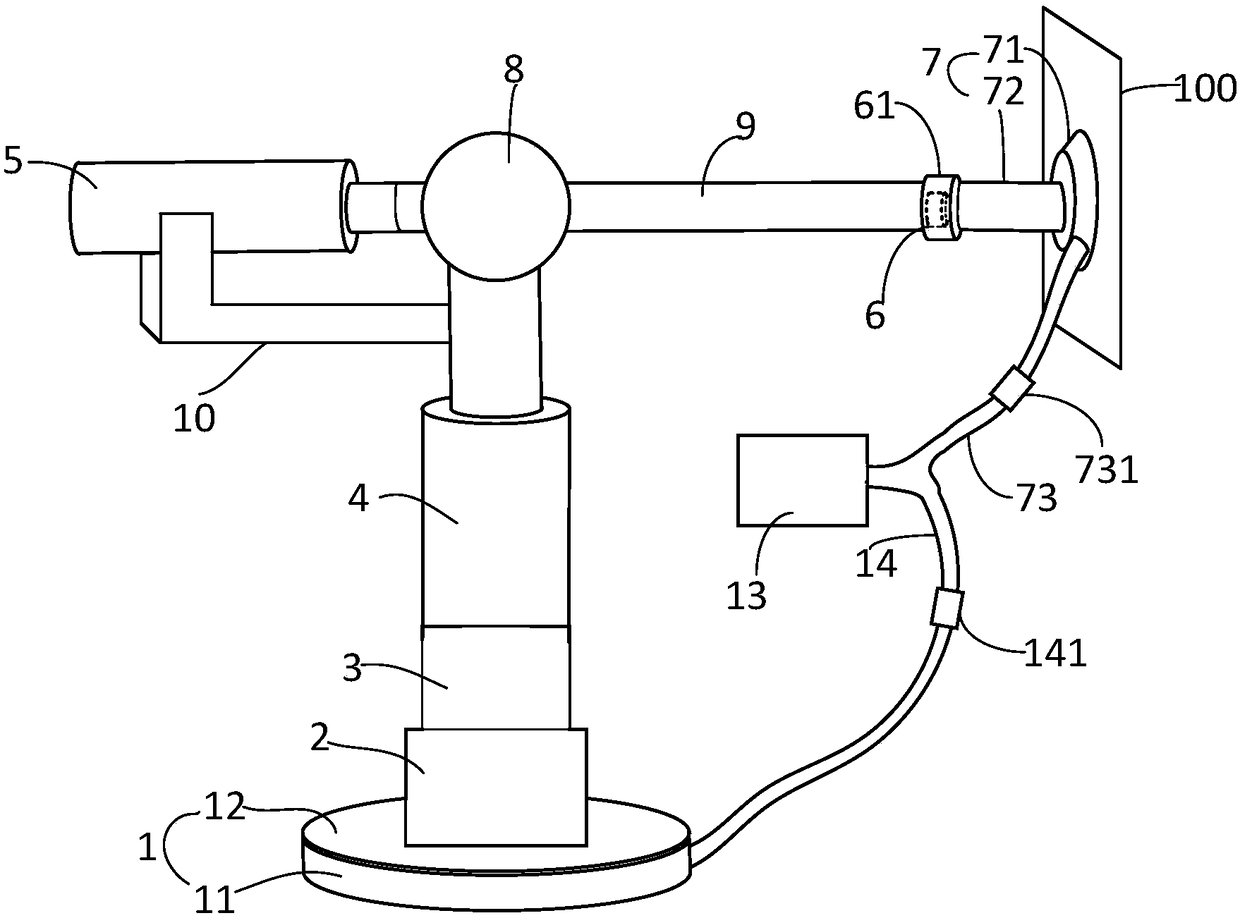

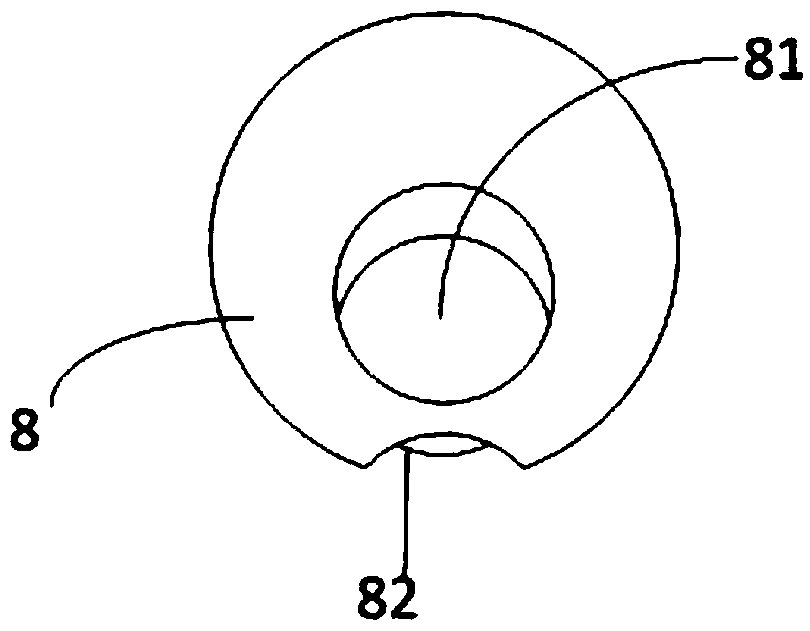

[0022] Such as figure 1 As shown, the present invention provides a device for testing the strength of veneer panels. The device includes a base 1, a horizontal rail 2 arranged above the base 1, a translation motor 3 arranged above the horizontal rail 2 and capable of translating along the horizontal rail 2, The first cylinder 4, the second cylinder 5, the elastic rod 9, the power supply, the spring dynamometer 6 and the veneer connection mechanism 7 for connecting the veneer 100 above the translation motor 3, the first cylinder 4 The cylinder barrel is connected with the translation motor 3 and its piston extends vertically upwards. The top end of the piston of the first cylinder 4 is fixed with a connecting mechanism 8. The piston of the second cylinder 5 is arranged horizontally in the axial direction and is coaxially connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com