Bracket tool for preventing rubber vulcanization deformation and operation method for preventing rubber vulcanization deformation

A rubber vulcanization and operation method technology, which is applied in the field of post-processing of rubber products, can solve problems such as limited oven space, low oven utilization rate, and product deformation, and achieve the effects of improving utilization rate, improving space utilization rate, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

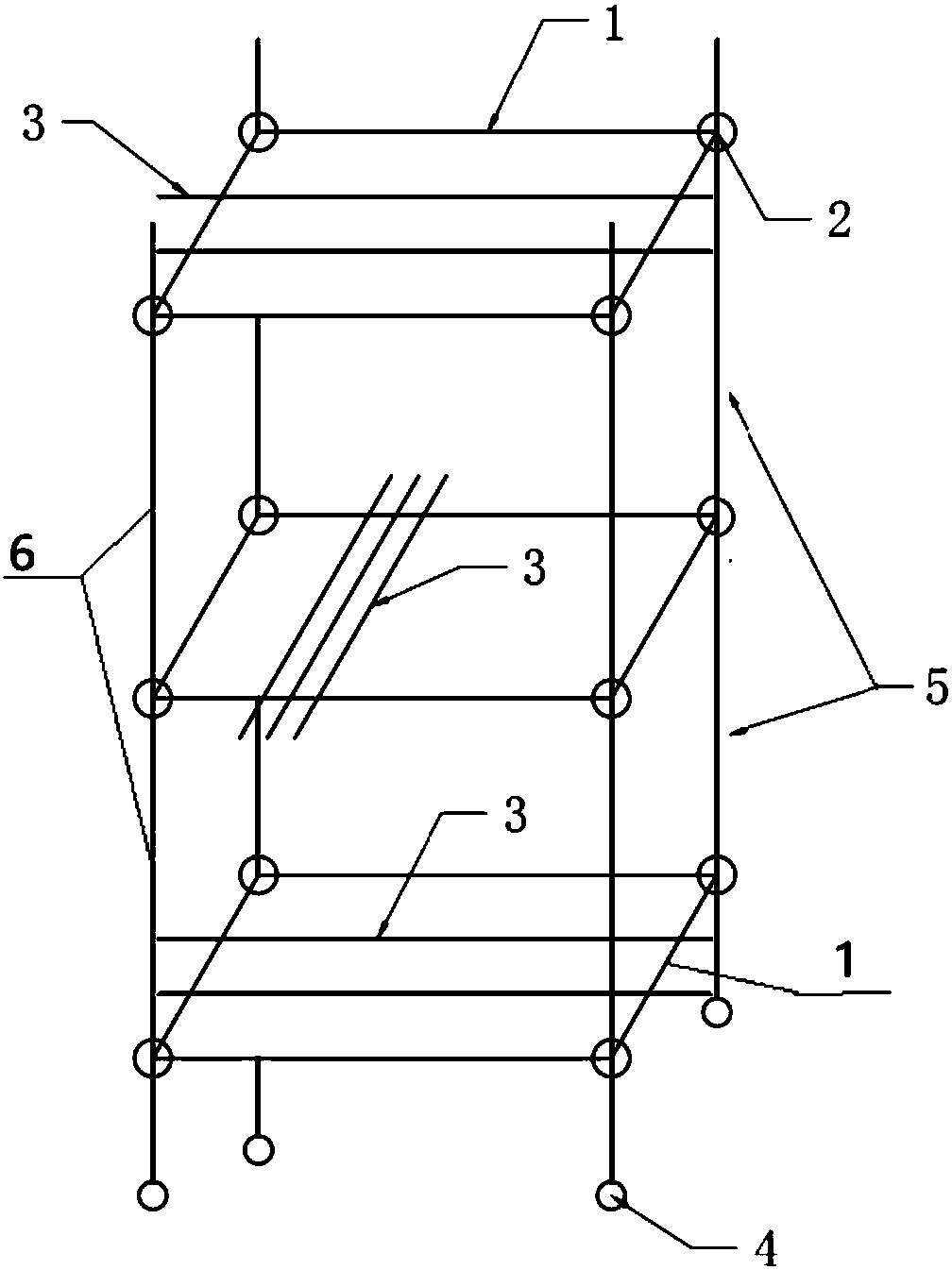

[0026] like figure 1 , the secondary vulcanization anti-deformation bracket tooling of the rubber special-shaped part of the present embodiment, it includes a bracket frame 5, figure 1 There are two layers of bracket frames 5 in the bracket tooling, which can be set into one layer, three layers, or even more layers according to needs. The number and size of bracket frames 5 can be adapted according to the size of the secondary vulcanization oven; figure 1 The stent frame 5 in is rectangular; As can be seen from the figure, the lower surface of the uppermost stent frame and the upper surface of the lowermost stent frame are common surfaces. Support frame 5 has crossbeam 1, vertical beam 6, because figure 1 There are two-layer support frames in the middle, for simplifying manufacture, the vertical beam 6 of two-layer support frame is a whole, and this vertical beam is telescopic. At the junction of the vertical beam 6 and the crossbeam 1, a height-adjustable tightening bolt 2 ...

Embodiment 2

[0039]The operation method of secondary vulcanization and anti-deformation of rubber special-shaped parts in this embodiment, the steps are:

[0040] (1) Height adjustment: According to the maximum length of the special-shaped rubber parts of 15CM, the partition height between the beams 1 on the upper and lower surfaces of the support frame is adjusted to 20CM by tightening the bolts 2.

[0041] (2) Rod threading: string the cylindrical stainless steel rod 3 into the end of the special-shaped parts, and string the special-shaped parts sequentially in the same direction and at the same position. The total length of the strings is slightly less than the length of the beam 1. Do not produce extrusion phenomena such as cross winding.

[0042] (3) Placing rods: place the stringed cylindrical stainless steel rods 3 on the beam 1 .

[0043] (4) Secondary vulcanization: set the temperature of the secondary vulcanization oven at 165° C. and the process conditions of 180 minutes, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com