Optical splitter

A technology of optical splitters and splitters, applied in the direction of light guides, optics, instruments, etc., can solve the problem of affecting the use effect and market expansion prospects, the capacity of fiber distribution cannot meet user requirements, and the inconvenience of expanding the network of optical splitters and other problems, to achieve the effect of convenient and quick adjustment of optical communication lines, convenient and flexible installation, and convenient plug-in and pull-out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

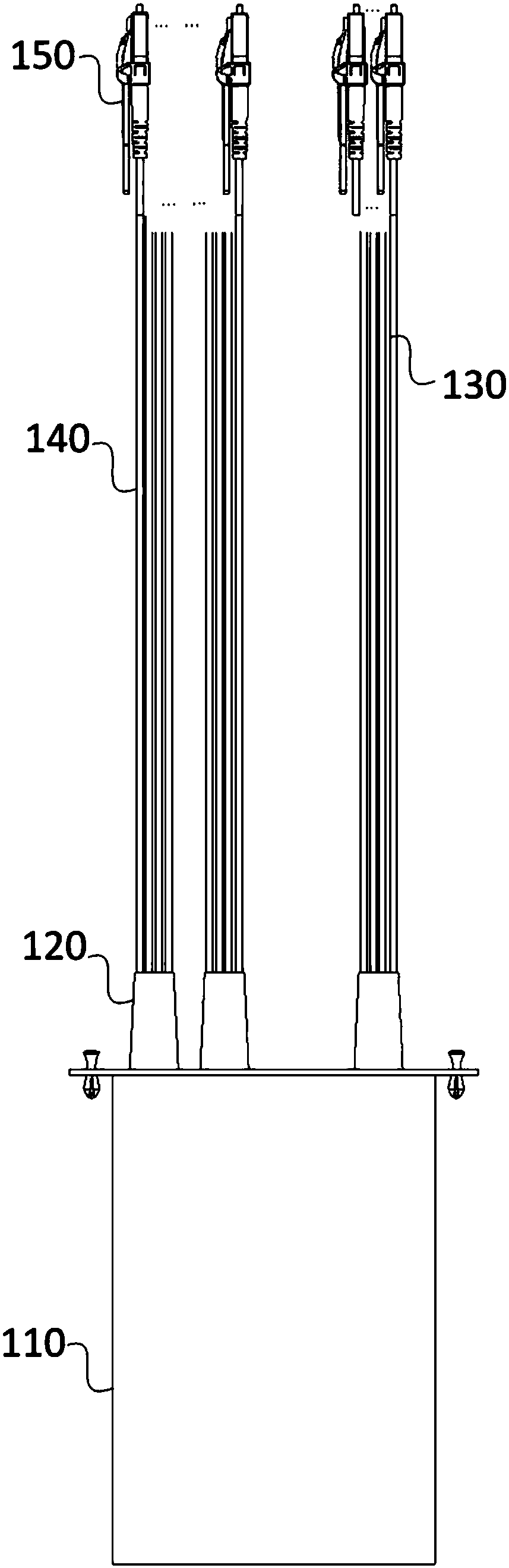

[0030] figure 1 It is a schematic structural diagram of the optical splitter in Embodiment 1 of the present invention, and this embodiment can be used in the case of splitting optical signals. Such as figure 1 As shown, the optical splitter includes: a module box 110 , a PLC splitter, a ferrule set 120 , an input optical fiber 130 , an output optical fiber 140 and an optical fiber connector 150 . Wherein, the PLC splitter is not shown in the figure.

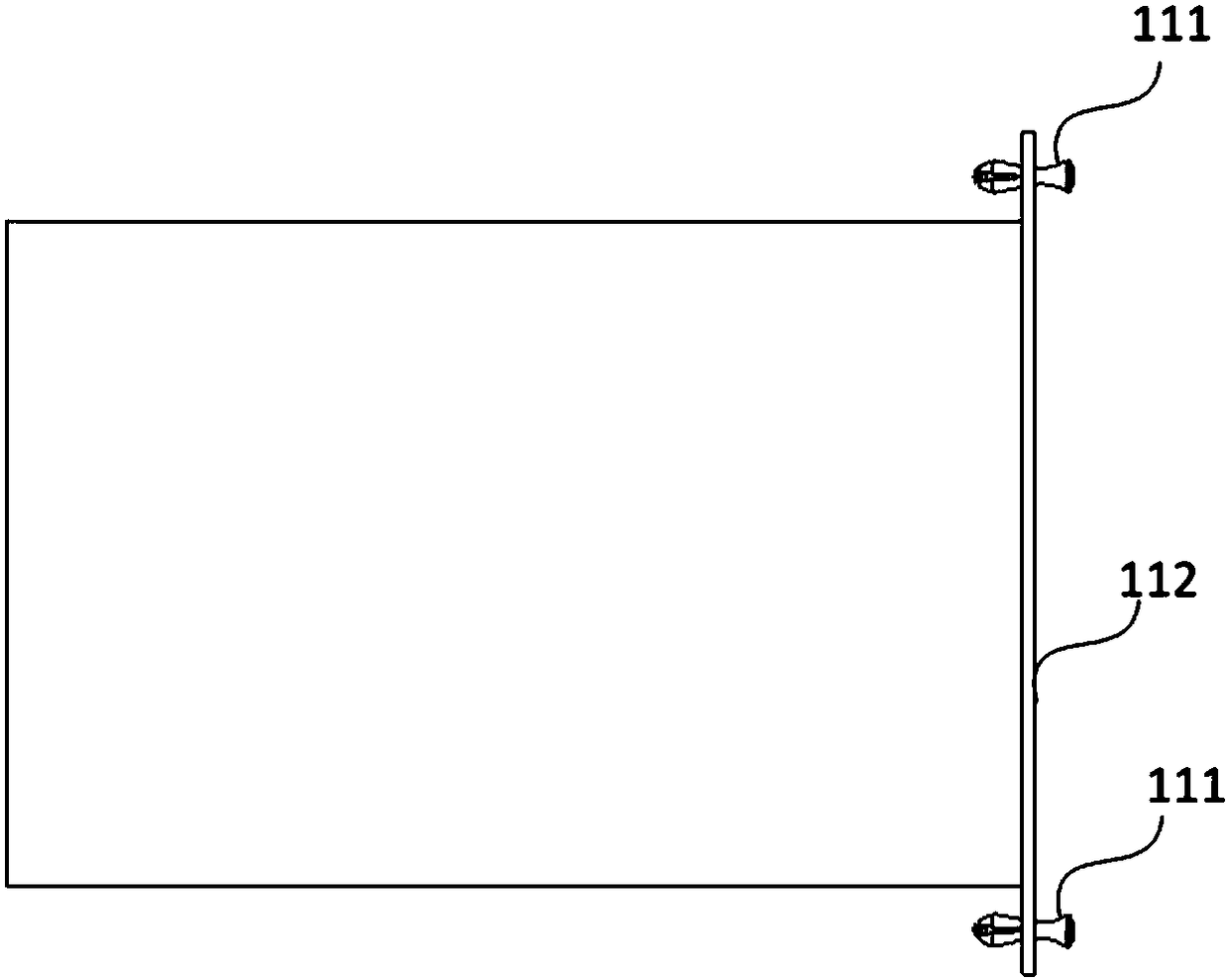

[0031] Specifically, the module box 110 includes at least one input panel hole and at least one output panel hole, and a bushing group 120 is respectively arranged in each said panel hole, and each group of bushings 120 includes at least one bushing; PLC branch The device is fixed inside the module box; the other end of the input optical fiber 130 at the input end of the PLC splitter extends to the outside of the module box 110 through the sleeve 120 arranged in the hole of the input panel, and is provided with an optical fiber...

Embodiment 2

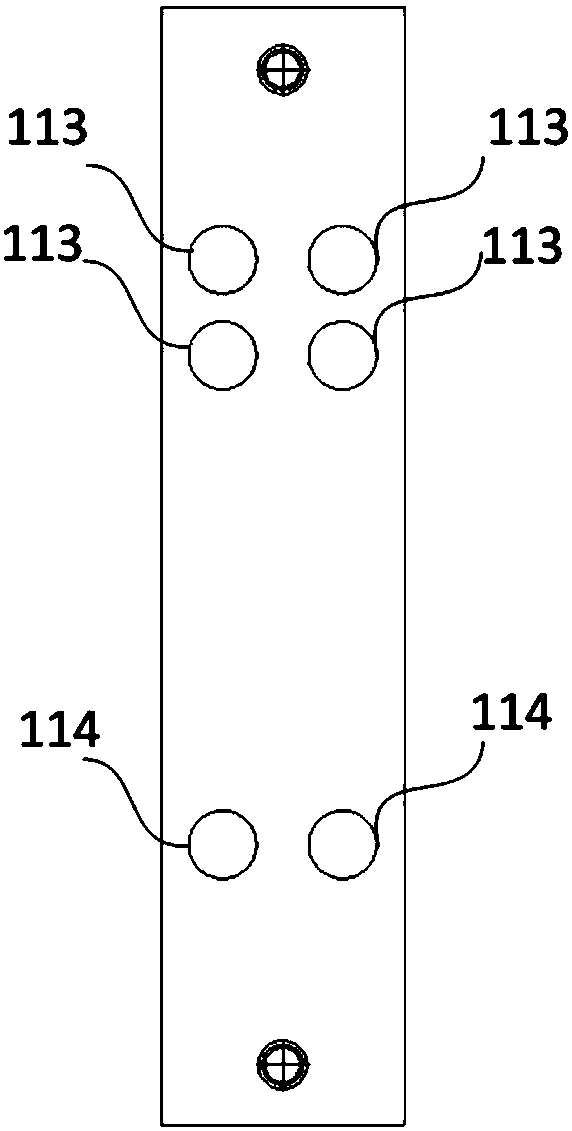

[0039] image 3 It is a schematic diagram of the connection mode of the optical fiber in the module box in the second embodiment of the present invention. This embodiment is based on the above-mentioned embodiment, and embodies the connection mode of the optical fiber in the module box.

[0040] Such as image 3 As shown, the PLC splitter 160 is fixed inside the module box 110, and the input end is on the side close to the panel hole 114, and the output end is on the side away from the panel hole 114. The input optical fiber 130 at the input end of the PLC splitter 160 extends to the outside of the module box 110 through the sleeve tube fixed in the input panel hole 114; the output optical fiber 140 at the output end of the PLC splitter 160 extends through the sleeve tube fixed in the output panel hole 113 to the outside of the module box 110. Wherein the casing is not shown in the figure.

[0041] Specifically, the PLC splitter is packaged into the LGX module box, and when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com