Workpiece attitude adjustment method based on measuring point and adaptive differential evolution algorithm

A technology of adaptive difference and evolutionary algorithm, applied in computer control, control/regulation system, instrument, etc., can solve problems such as difficult surface parameter equations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

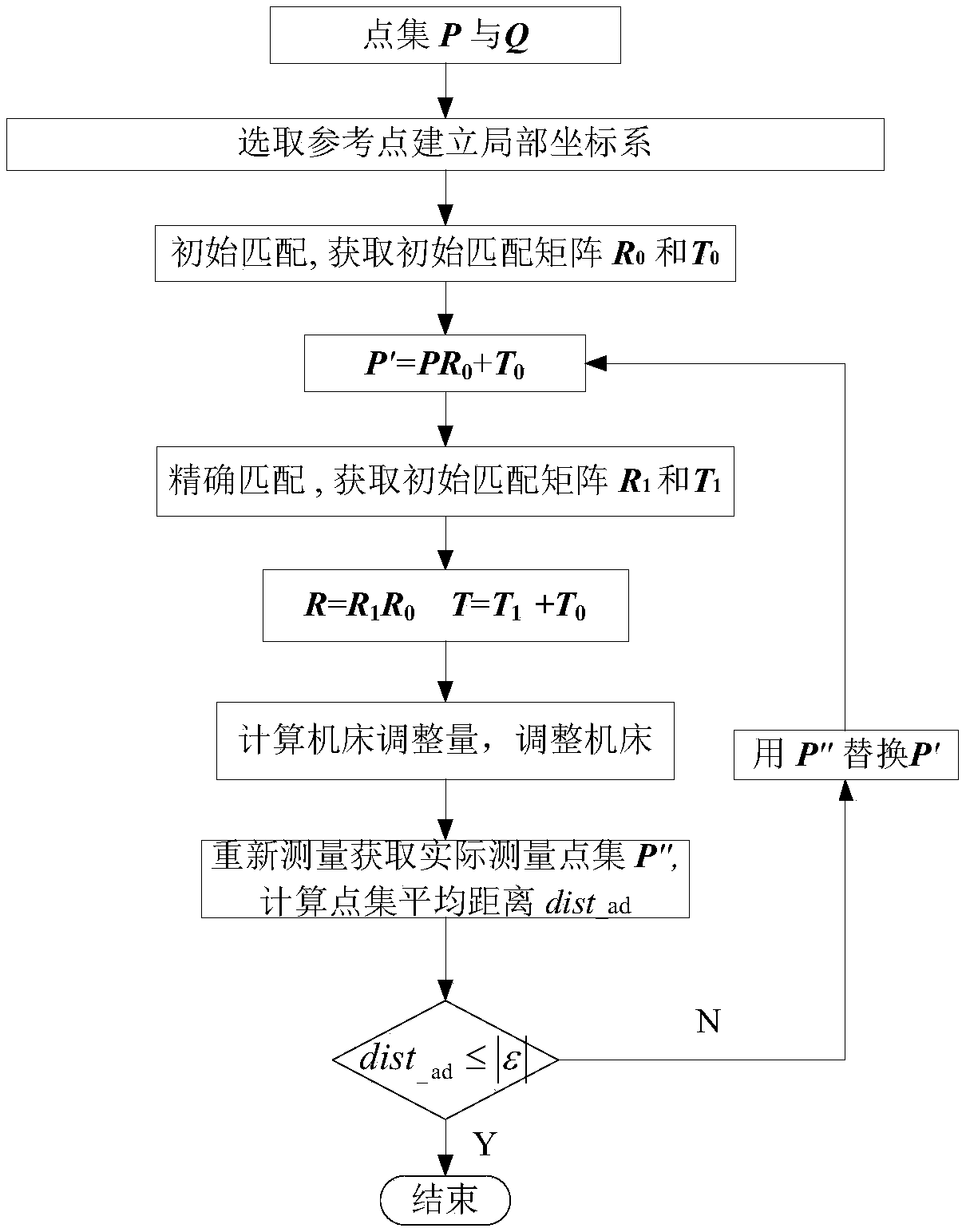

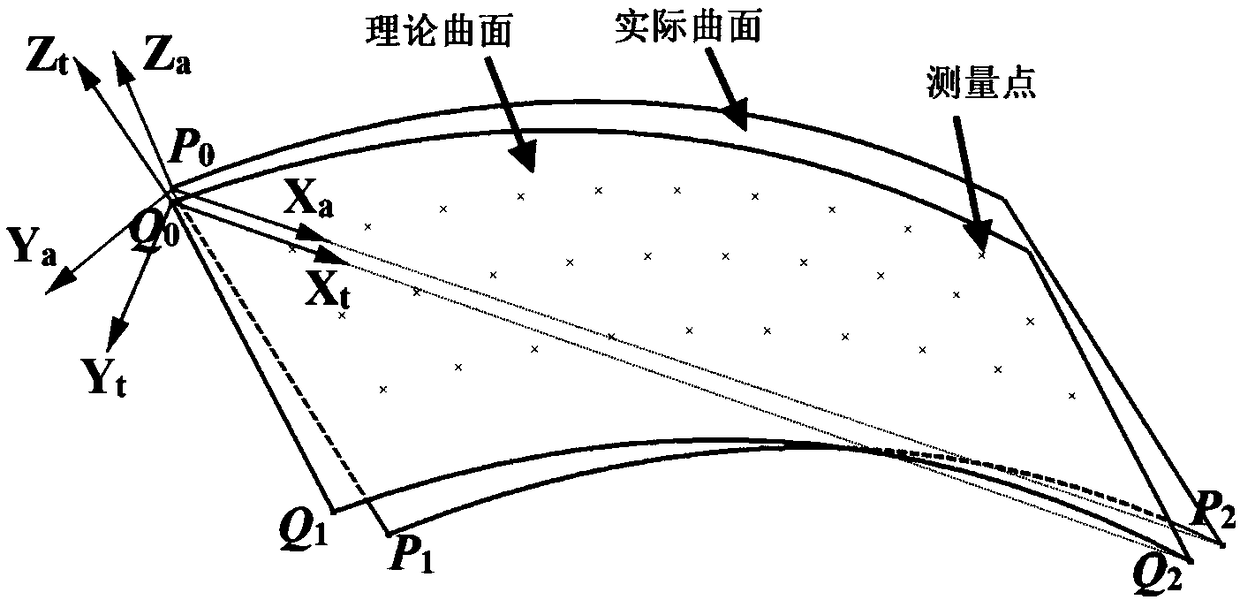

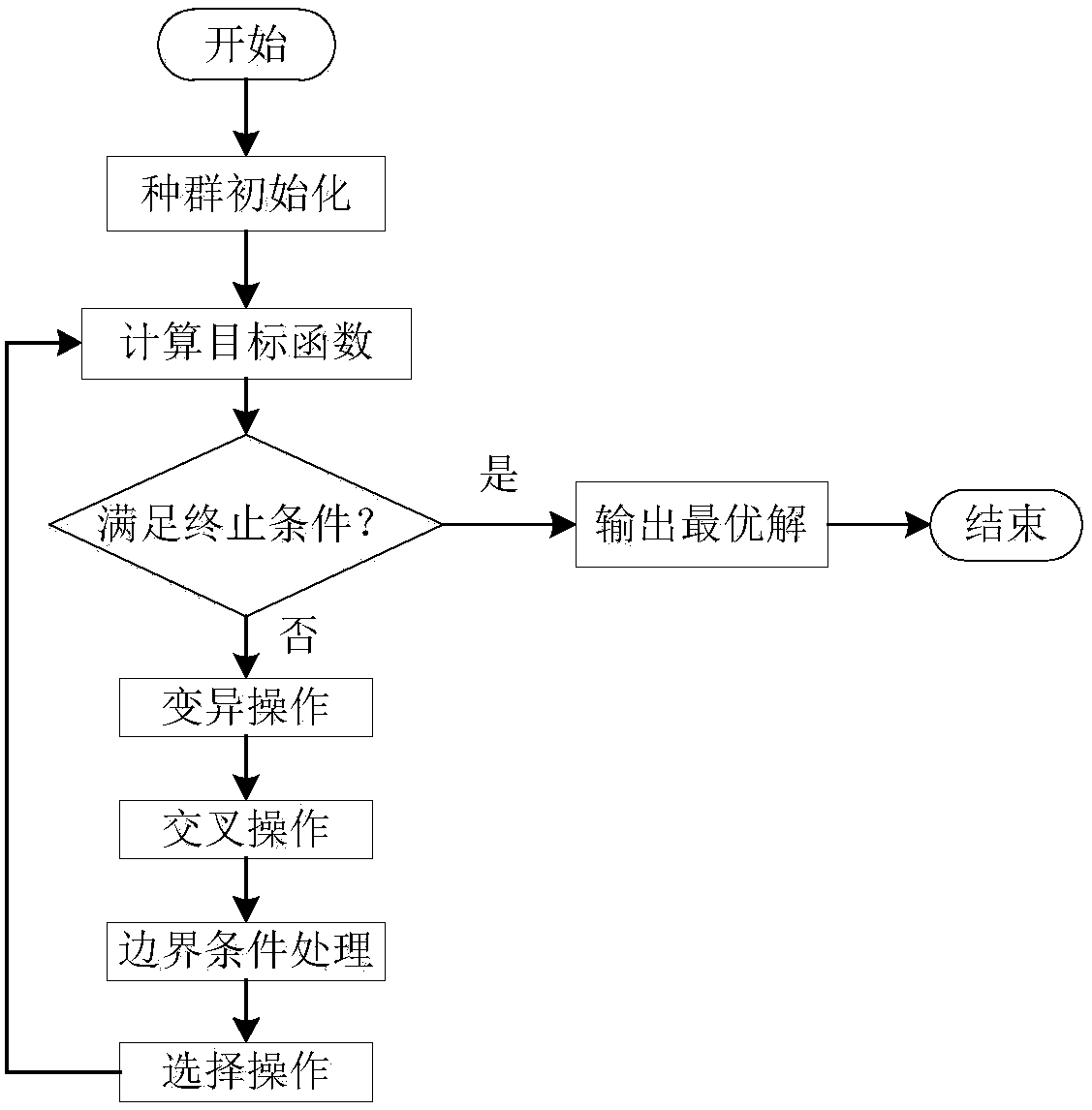

[0065] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The invention proposes a new matching algorithm to realize real-time adjustment of workpiece posture. The proposed algorithm includes initial matching and exact matching. The adaptive differential evolution algorithm (SADE) is introduced in the exact matching link to search for the best exact matching matrix, and the optimal spatial rotation of the actual point set relative to the theoretical point set is obtained through step-by-step matching. Transformation matrix R and translation transformation matrix T. Finally, the adjustment parameters of the machine tool are obtained according to the optimal transformation matrix combined with the structure of the machine tool, and the adjustment of the workpiece posture is realized.

[0066] Do point set matching:

[0067] Set the actual measurement point set of the feature surface of the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com