Clamp tool of tightening arm

A fixture and tooling technology, which is applied in the field of clamping and tooling of the tensioning arm, can solve the problems of discounted pin positioning effect, failure to meet parallelism requirements, large impact and vibration, etc., achieve convenient positioning effect, improve fixing effect, and reduce shaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

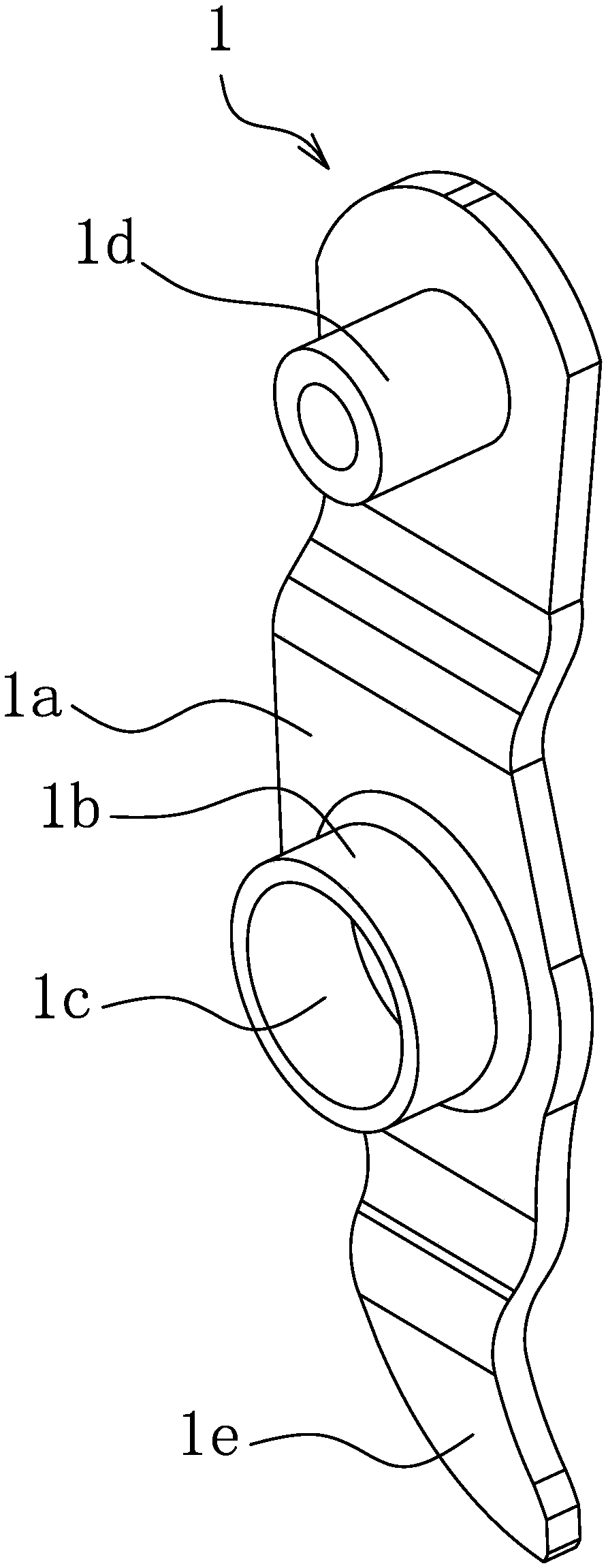

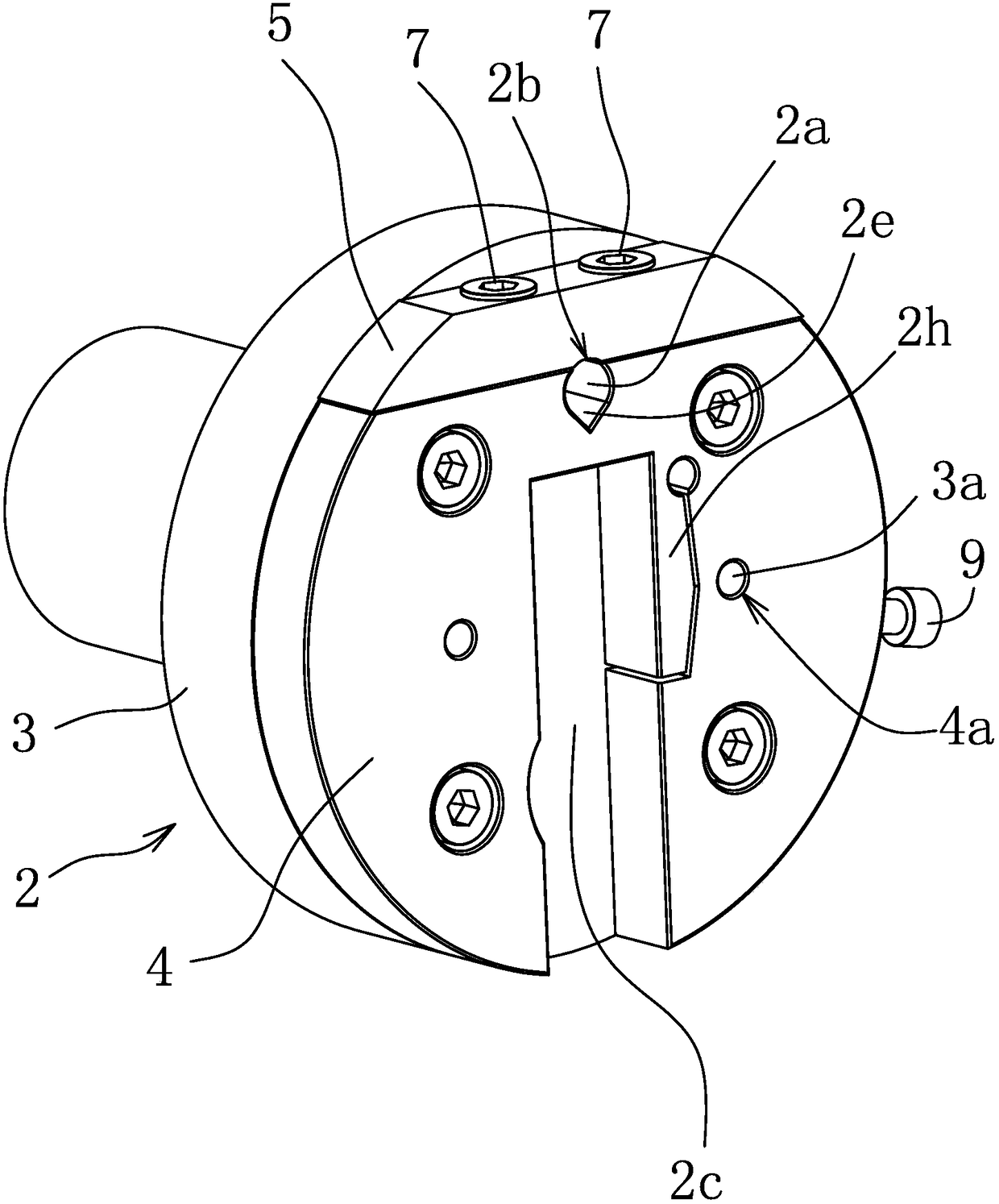

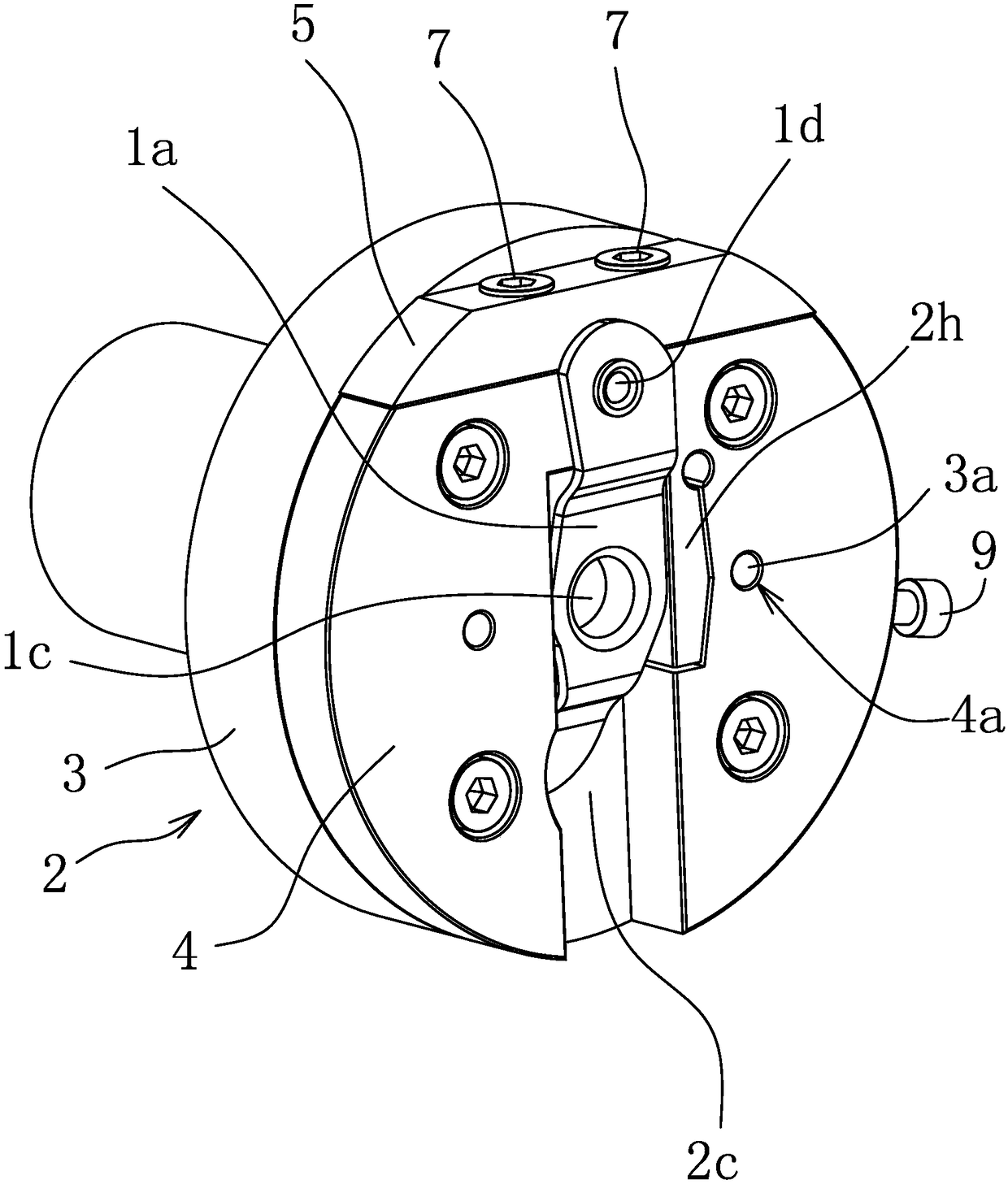

[0039] Such as Figure 2-Figure 6 As shown, a clamp tooling for a tensioning arm includes a connecting seat 2 that can rotate. A pressure plate 5 is provided on the front side of the connecting seat 2 through a pressing member. The contact surface of the connecting seat 2 and the pressure plate 5 The shape is the same, and the mounting hole 2b and mounting hole 2b for clamping the pin 1d in the tensioning arm 1 are formed by opening a straight groove 2a on the contact surface of the connecting seat 2 or / and the pressure plate 5 between the two The axial direction of is parallel to the rotation axis of the connecting seat 2. The straight groove 2a is an arc-shaped groove for mating with the pin shaft 1d, and a strip-shaped relief groove 2e is provided on the bottom surface of the straight groove 2a. A spacer 6 is fixed in the mounting hole 2b so that the axial depth of the mounting hole 2b is smaller than the axial length of the pin shaft 1d. The edge of the mounting hole 2b is...

Embodiment 2

[0045] Such as Figure 7 As shown, the front end surface of the connecting seat 2 is provided with a stopper 2d into which the main body 1a of the tensioning arm 1 is placed to prevent swinging around its pin 1d, and an abutting member 2h is provided on the connecting seat 2 at the stopper 2d, A push rod 9 is connected to the connecting base 2. One end of the abutment member 2h can be fixed to the connecting seat 2, and one end of the push rod 9 abuts on the abutment member 2h; the abutment member 2h can be separated from the connection seat 2, and the abutment member 2h is connected to one end of the push rod 9. The other structure is the same as the first embodiment.

Embodiment 3

[0047] The pressing part is a pressing cylinder, and the piston rod of the pressing cylinder is fixedly connected with the pressing plate 5. The push rod 9 is a straight rod, a positioning cylinder is connected to the push rod 9, and the piston rod of the positioning cylinder is fixedly connected with the push rod 9. Both the compression cylinder and the positioning cylinder are electrically connected to the control panel of the machine tool to realize automatic clamping and improve production efficiency. The other structure is the same as the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap