Bi-component starch-based adhesive for wood

A two-component, wood-based technology, applied in the direction of starch-derived adhesives, adhesive additives, polymer adhesive additives, etc., can solve problems such as poor water resistance, improve water resistance and mechanical properties, and improve water resistance Performance, the effect of maintaining air resistance

Inactive Publication Date: 2018-07-17

王建东

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The main technical problem to be solved by the present invention is: Aiming at the problem of poor w

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

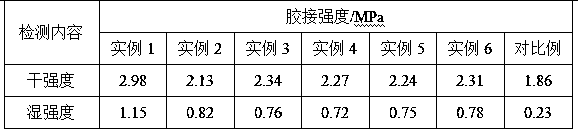

The invention discloses a bi-component starch-based adhesive for a wood and belongs to the technical field of deep processing of woods. The bi-component starch-based adhesive for the wood is formed byseparately packaging a component A and a component B, wherein the component A is prepared by adding 40-50 parts of starch paste, 20-30 parts of activated chitosan, 10-20 parts of humic acid, 10-20 parts of modified additive and 10-20 parts of nanometer silica into a 3# beaker according to part weight, and carrying out stirring and mixing at the rotating speed of 300-500r/min for 40-60min; and thecomponent B is prepared by adding 10-20 parts of isocyanate, 8-10 parts of konjac glucomannan, 8-10 parts of silane coupling agent and 3-5 parts of crosslinking agent into a 4# beaker according to part weight, and carrying out stirring and mixing at the rotating speed of 300-500r/min for 40-60min. By using the bi-component starch-based adhesive for the wood, provided by the invention, a system isenabled to have excellent water resistance and mechanical properties.

Description

technical field [0001] The invention discloses a two-component starch-based adhesive for wood, which belongs to the technical field of wood deep processing. Background technique [0002] Adhesives play a pivotal role in the full utilization of wood resources, such as traditional urea-formaldehyde resins, phenolic resins, melamine-formaldehyde resins, etc. Among the existing woodworking adhesive systems, the fatal defect of formaldehyde-based adhesives is that during the production and use of bonded wood products, harmful gases such as free formaldehyde will inevitably be released, which will endanger producers and consumers. The health of the body; water-based adhesives use water as the dispersion medium, are odorless, non-polluting, and are environmentally friendly adhesives. Although water-based polymeric isocyanate adhesive (API) does not release free formaldehyde, its high viscosity, short pot life and high cost limit its wide application in wood gluing. However, with ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J103/10C09J105/08C09J105/02C09J11/04C09J11/06C09J11/08

CPCC09J103/10C08K2201/011C08L2205/035C09J11/04C09J11/06C09J11/08C08L5/08C08L5/02C08L51/08C08K13/02C08K5/29C08K3/36C08K5/5435C08K5/544C08K5/5419

Inventor 王建东殷连海张淼

Owner 王建东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com