A vibration cutting impact drop test device and its working method

A technology of vibrating cutting and experimental equipment, which is applied in the direction of measuring equipment, testing of mechanical components, testing of machine/structural components, etc., can solve the problem that the cutting process cannot be well simulated, cutting parameters cannot be well controlled, and it is difficult to capture To the cutting cycle and other issues, to achieve the effect of improving the automation level and modifying the parameters conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

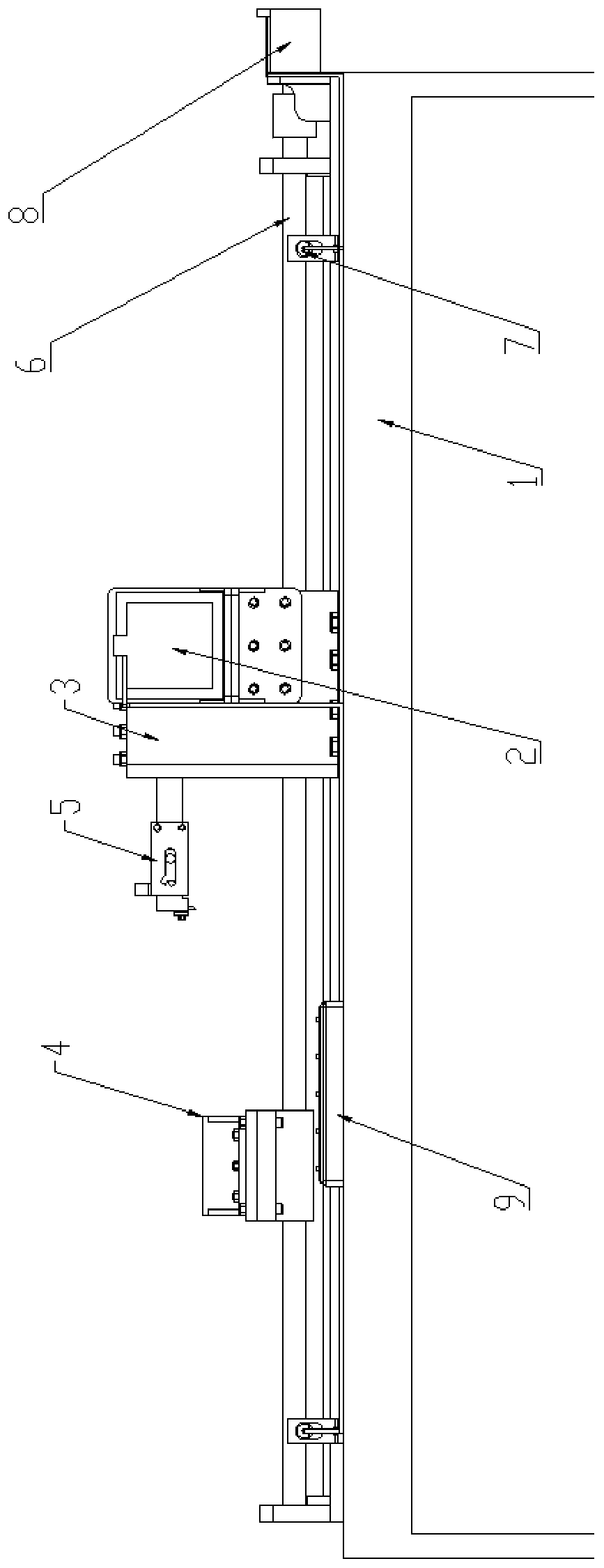

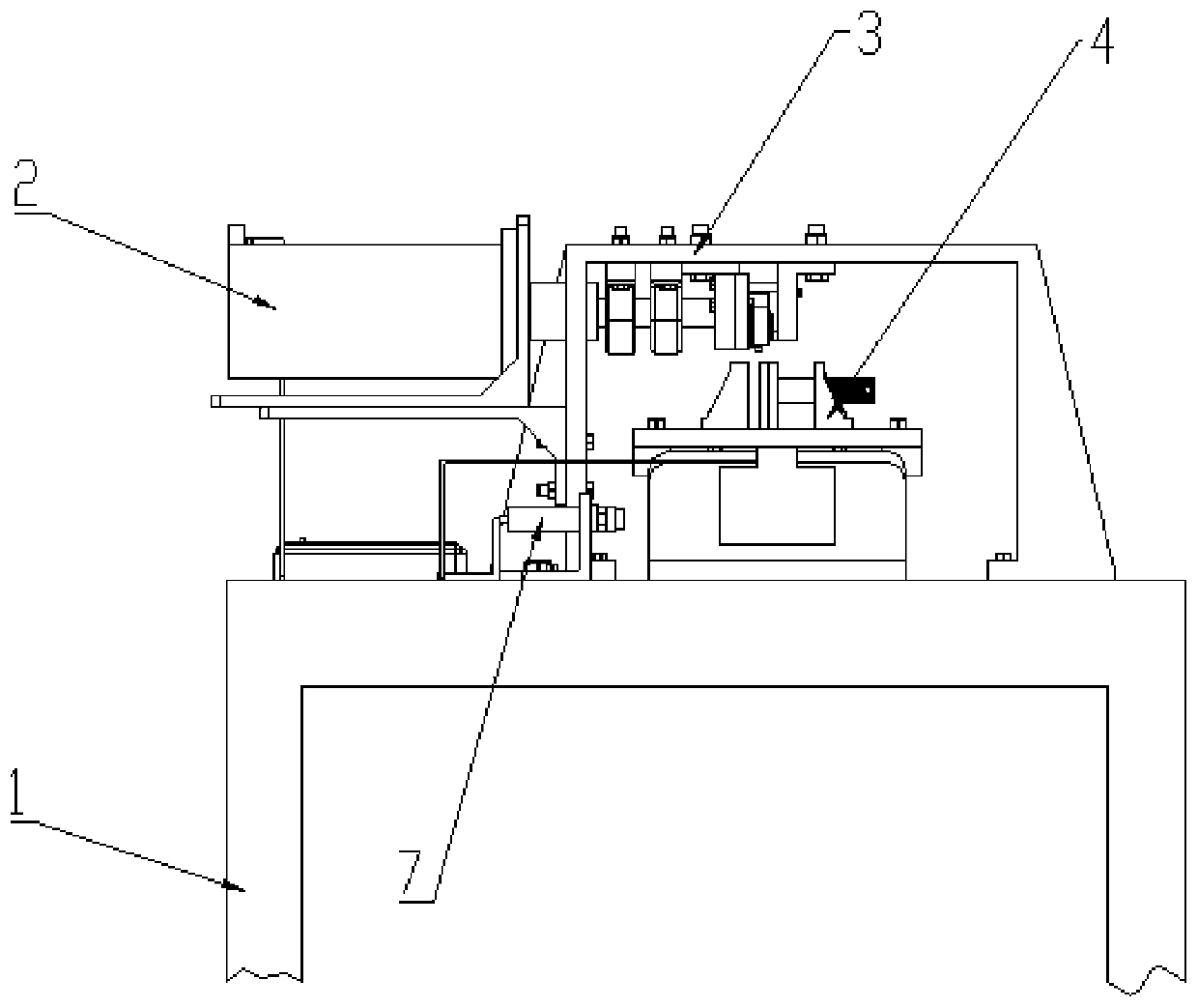

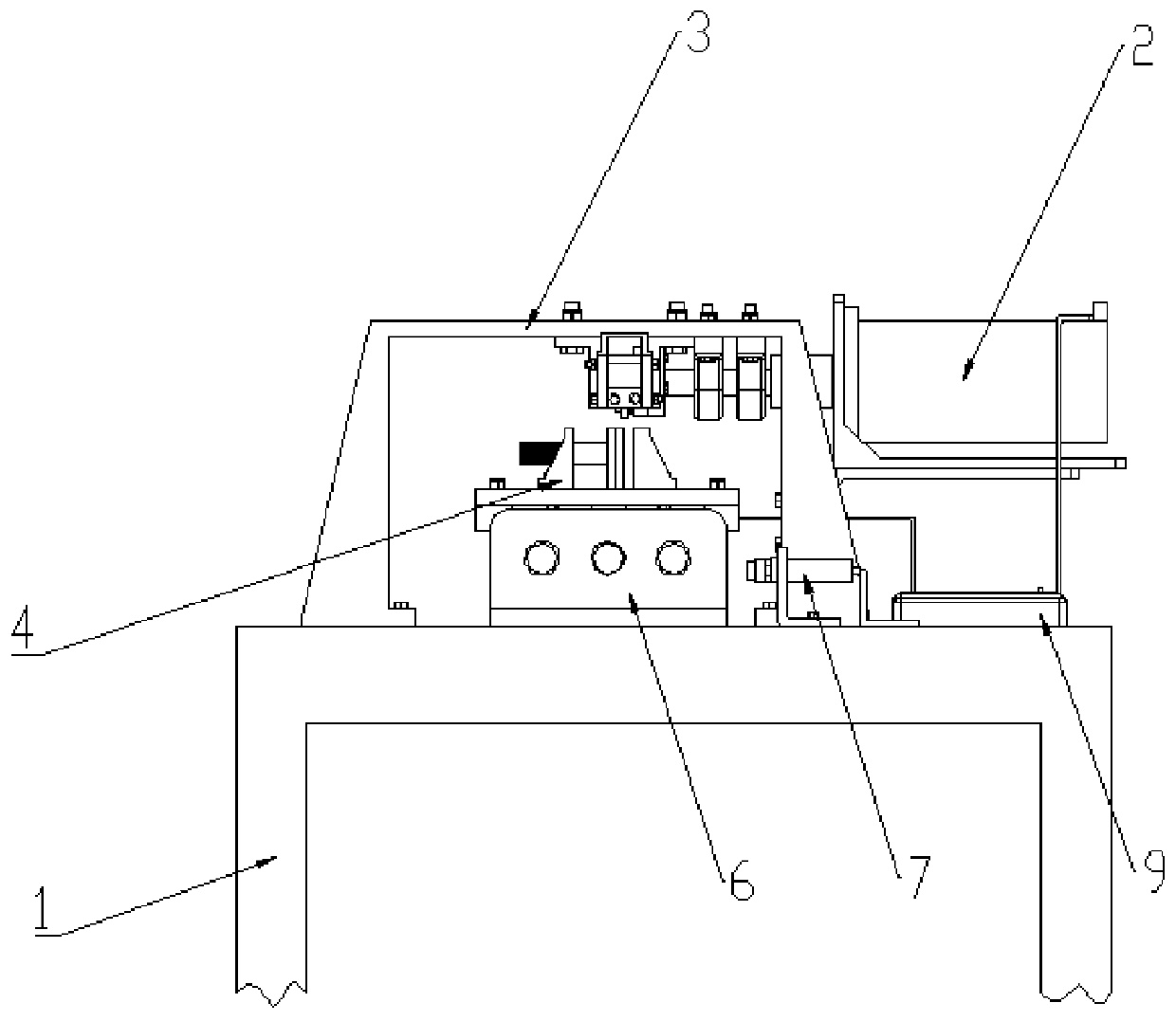

[0036] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-12 As shown in the figure, an experimental device for simulating vibration cutting impact tool drop, including workbench 1, fixture 4, slide table, stepping motor A8, vibration cutting device and control device;

[0037] The slide table is installed on the workbench 1, the clamp 4 is installed on the moving panel of the slide table, and the stepper motor A8 is installed on the motor bracket of the slide table, and the step motor A8 is connected to the slide table through the plum blossom coupling. screw connection;

[0038] The vibration cutting device includes a knife drop module 5 and a vibration generation module 3, and the knife drop module 5 includes a cutter 24, a pressing blade 25, a knife drop slide bar 23, a knife drop shell, a spring frame 21 and a spring B28; The falling knife shell described above is formed by two side plates 22 and a rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com